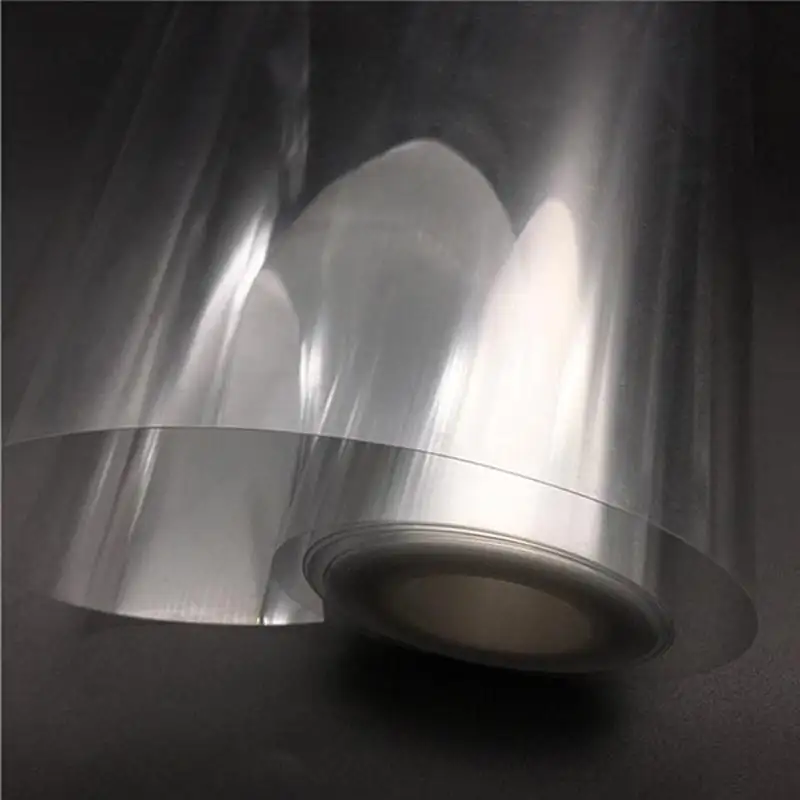

0.2 mm PET plastic sheet

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "0.2 mm PET plastic sheet", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Brief introduction of 0.2 mm PET plastic sheet

A 0.2 mm PET plastic sheet is a thin, flexible sheet made from polyethylene terephthalate (PET), a type of polyester. PET is commonly used for various applications due to its excellent properties:

Key Characteristics

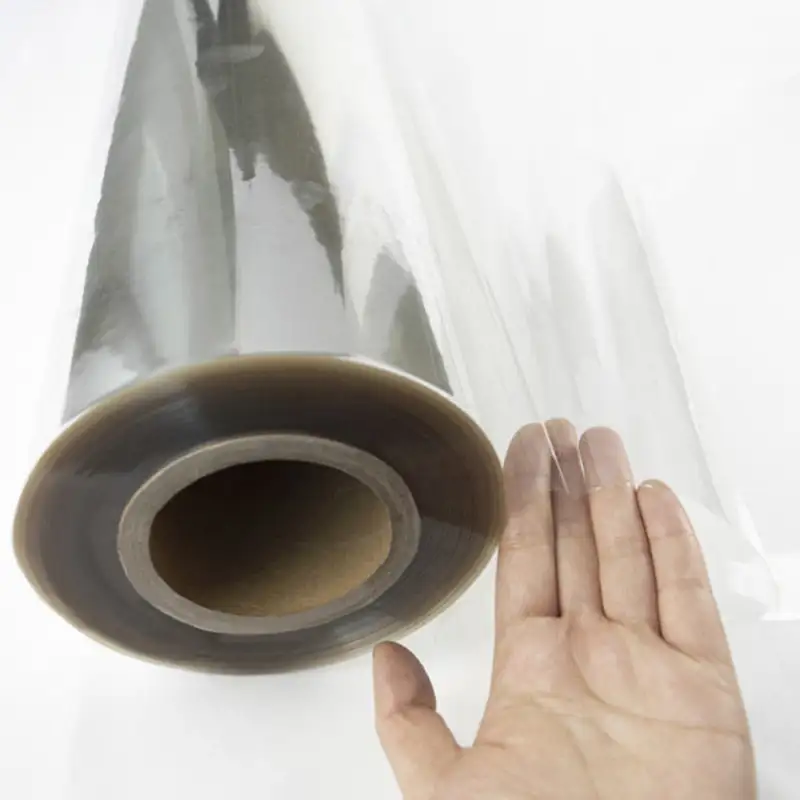

Thickness: 0.2 mm, which is quite thin and allows for flexibility.

Transparency: PET plastic sheets are often clear, providing high clarity.

Strength: Despite being thin, PET plastic sheet is known for its durability and toughness.

Chemical Resistance: PET is resistant to many chemicals, including acids and oils.

Barrier Properties: PET provides a good barrier against moisture and gases, making it suitable for packaging.

Product Application of 0.2 mm PET plastic sheet

The 0.2 mm PET plastic sheet is suitable for packaging a wide range of products due to its excellent physical and chemical properties. Below are some common application areas:

1. Food Packaging

(1) Beverage Bottles: PET is a common material for making beverage bottles, especially for water, juices, carbonated drinks, etc. Although 0.2 mm thickness is quite thin, it can be used for sealing bottle necks or caps.

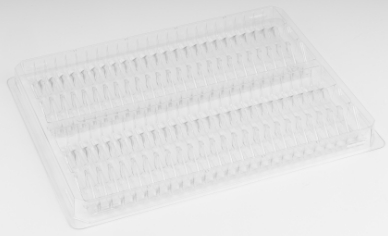

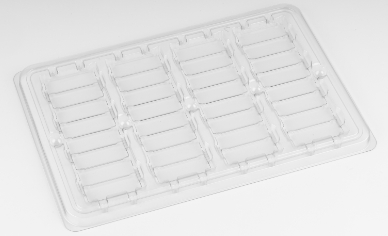

(2) Trays and Lids: Used for packaging fresh fruits, vegetables, deli products, etc. This thin sheet material can be made into transparent trays or lids, allowing consumers to see the contents.

(3) Blister Packaging: 0.2 mm PET plastic sheets can be used to create blister packaging for candies, nuts, small snacks, etc.

2. Pharmaceutical and Medical Product Packaging

(1) Pharmaceutical Blister Packaging: Used for packaging tablets or capsules, this thin sheet material provides protection and prevents contamination.

(2) Medical Device Packaging: Used for packaging disposable medical devices such as syringes, surgical blades, etc.

3. Electronics Packaging

(1) Electronic Component Protection: The 0.2 mm PET sheet can be used for packaging and protecting sensitive electronic components such as chips, circuit boards, etc., preventing static and mechanical damage.

4. Cosmetics and Personal Care Product Packaging

(1) Cosmetic Trays: Used for packaging transparent trays for cosmetics such as powder, eyeshadow, etc.

(2) Personal Care Product Packaging: Used for packaging personal care items like razor blades, toothbrushes, etc.

5. Stationery and Office Supplies Packaging

(1) Stationery Packaging: Transparent blister packaging for items such as pens, erasers, file folders, etc.

(2) Document Protectors: Used to make transparent document protectors or sleeves to keep documents clean and organized.

6. Toys and Small Goods Packaging

(1) Toy Packaging: Used for transparent blister packaging to display small toys or models.

(2) Gift Packaging: 0.2 mm PET plastic sheet used as part of gift boxes to enhance product display.

Due to its excellent transparency, mechanical strength, and chemical stability, the 0.2 mm PET plastic sheet is widely used in packaging for these types of products.

Processing Process of 0.2 mm PET plastic sheet

The production of 0.2 mm PET plastic sheets involves several steps, from raw material preparation to the final sheet formation. Below is an overview of the production process:

1. Raw Material Preparation

PET Resin: The primary raw material for producing PET plastic sheets is PET (Polyethylene Terephthalate) resin pellets.

Additives: Depending on the requirements, additives such as antioxidants, plasticizers, colorants, and UV stabilizers can be added to enhance the sheet’s properties.

2. Drying Process

PET resin pellets typically need to be dried in a dryer to remove moisture. PET is highly sensitive to moisture, and excessive moisture can lead to quality issues in the sheets, such as bubbles and reduced transparency. The drying temperature is usually around 160°C, with a drying time of 4-6 hours.

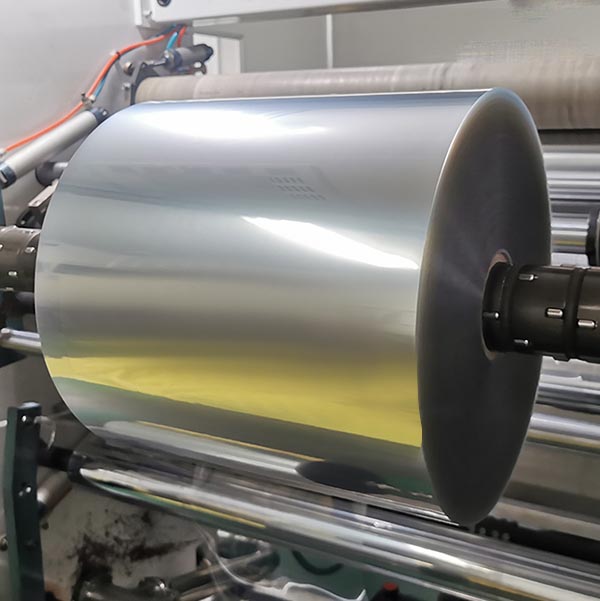

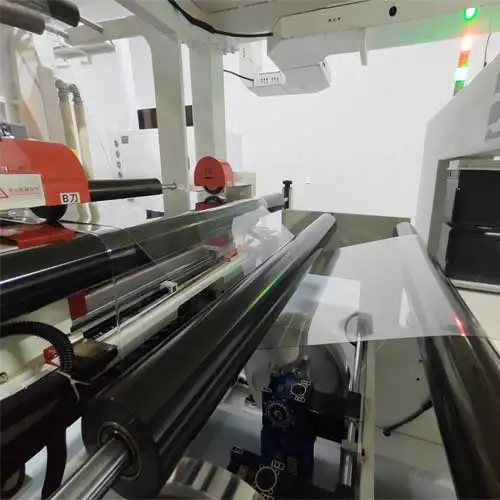

3. Extrusion Process

Extruder: The dried PET pellets are fed into a screw extruder, where they are heated and melted. The extruder heats the solid PET pellets to a molten state, typically at temperatures between 260°C and 290°C.

Filter: The molten PET is passed through a filter to remove impurities, ensuring the purity of the material.

Die Extrusion: The molten PET is then extruded through a flat die, forming a molten film.

4. Cooling and Forming

Calendering and Cooling: The molten PET film is passed through a calender (typically a three-roll calender) to press it into a sheet of uniform thickness. The cooling rolls then cool and set the sheet. For a 0.2 mm thickness, precise control of roll spacing and cooling speed is required to ensure uniform thickness and a smooth surface.

Edge Trimming: The formed sheet passes through an edge trimming device to remove excess material from the edges.

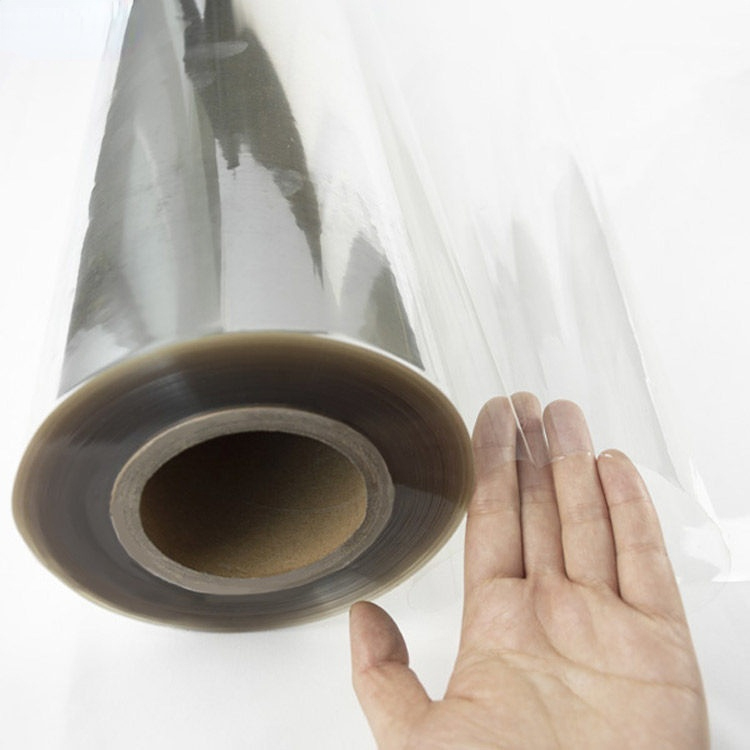

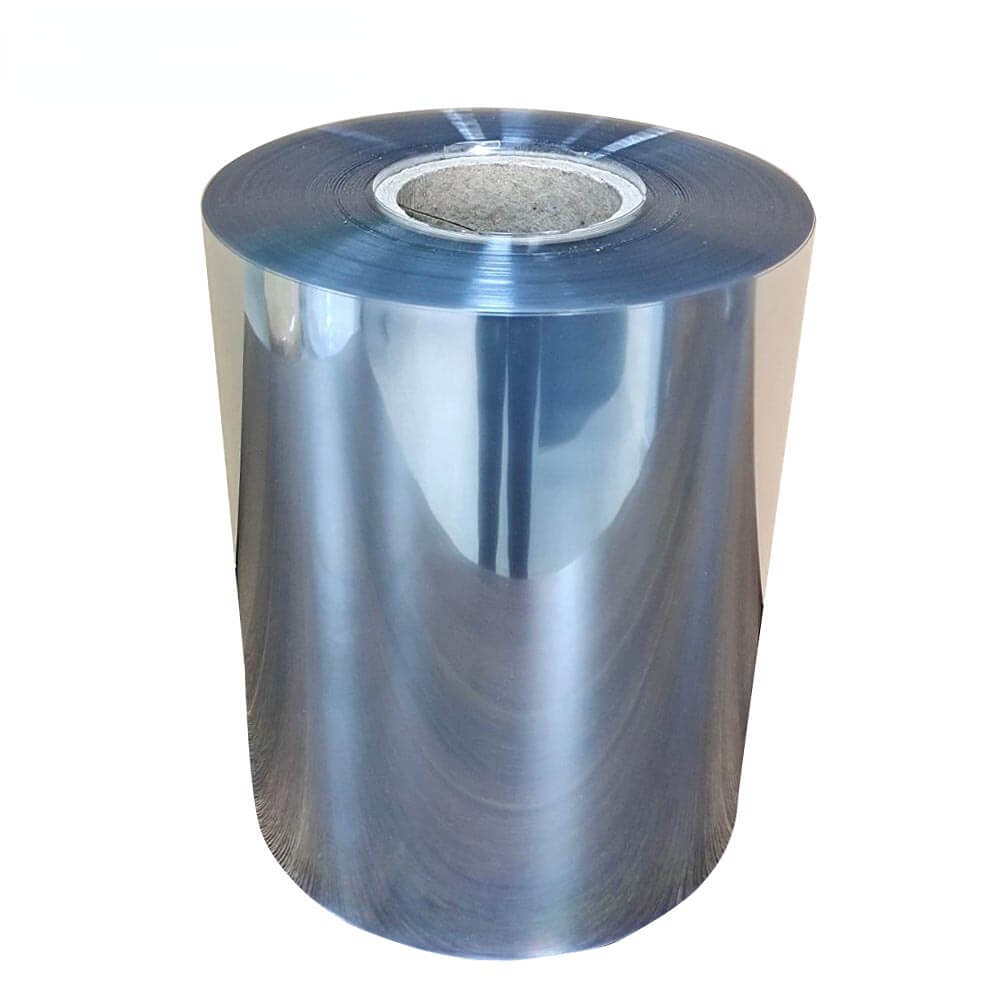

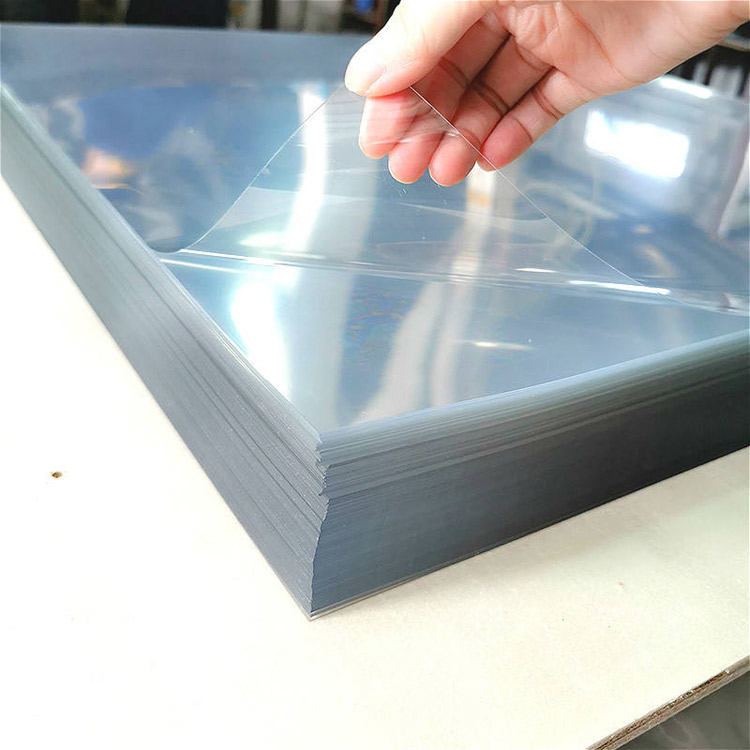

5. Winding and Cutting

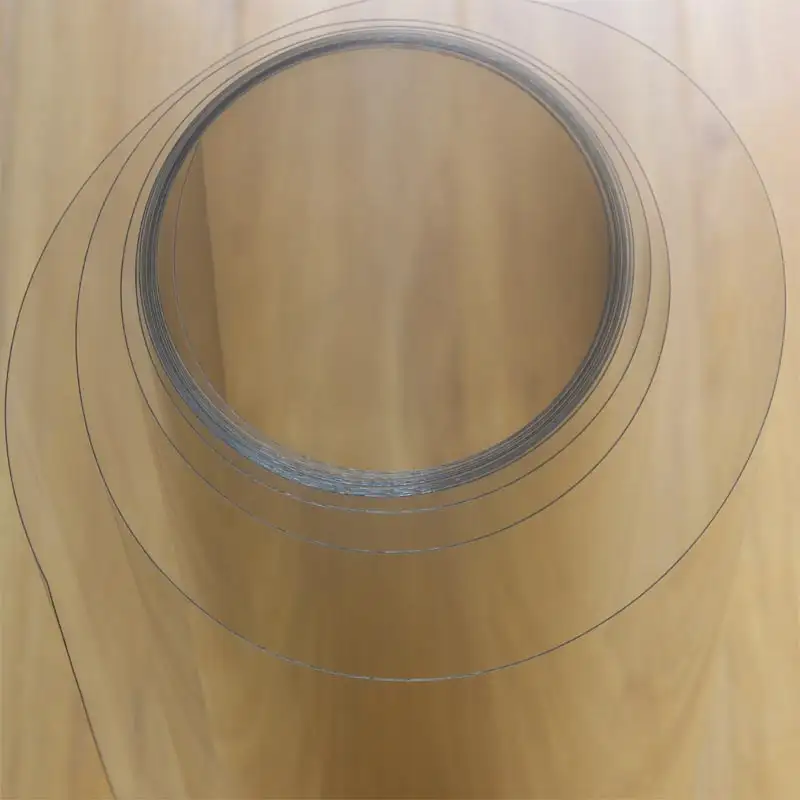

Winding: The cooled sheet is wound into large rolls for easy handling and transportation.

Cutting: The sheet can be cut into specific sizes and shapes according to customer requirements.

6. Quality Control

Thickness Testing: A thickness gauge is used to measure the sheet’s thickness to ensure it meets the 0.2 mm specification.

Surface Inspection: The sheet surface is inspected for defects such as bubbles, particles, or scratches.

Physical Performance Testing: Tests are conducted for tensile strength, transparency, and other properties to ensure the sheet meets quality standards.

7. Packaging and Storage

Packaging: The qualified sheets are packaged according to specifications to prevent damage during transportation.

Storage: The packaged sheets should be stored in a dry, shaded environment to prevent aging and contamination.

This production process requires precise equipment and strict process control. In thin 0.2mm pet plastic sheet production, consistency in thickness and surface quality is crucial. The level of automation, the quality of raw materials, and the setting of process parameters all impact the final product’s quality.

Product Advantages of 0.2 mm PET plastic sheet

A 0.2 mm PET plastic sheet offers several advantages across various applications. Here are the key benefits:

1. High Transparency

0.2 mm PET plastic sheets are known for their excellent clarity and transparency, making them ideal for applications where visibility of the product is essential, such as packaging.

2. Strong Barrier Properties

0.2 mm PET plastic sheet has excellent barrier properties against moisture, gases, and other environmental factors, helping to preserve the freshness and integrity of packaged goods.

3. Mechanical Strength

Despite its thinness, a 0.2 mm PET plastic sheet offers good tensile strength, impact resistance, and durability, making it suitable for a variety of uses, including protective covers and packaging.

4. Lightweight

The thin profile of 0.2 mm PET plastic sheet ensures that it adds minimal weight to products, which is particularly beneficial for packaging and shipping.

5. Chemical Resistance

0.2 mm PET plastic sheet is resistant to a wide range of chemicals, including acids, oils, and alcohols, making it a good choice for packaging food, pharmaceuticals, and other sensitive products.

6. Recyclability

0.2 mm PET plastic sheet is widely recyclable, making it an environmentally friendly option. The thin sheet can be easily recycled into new products, contributing to a circular economy.

7. Flexibility and Formability

The thin 0.2 mm PET plastic sheet is flexible and can be easily thermoformed into various shapes without compromising its structural integrity, which is useful in packaging and other industrial applications.

8. Cost-Effective

0.2 mm PET plastic sheets are relatively inexpensive compared to other types of plastic sheets, providing a cost-effective solution for manufacturers and end-users.

9. Safe for Food Contact

0.2 mm PET plastic sheet is FDA-approved for direct food contact, making the 0.2 mm sheet suitable for food packaging applications.

10. UV Resistance

PET offers good resistance to UV radiation, helping to protect the contents of the packaging from sunlight and prolonging shelf life.

These advantages make 0.2 mm PET plastic sheets a versatile and practical material in industries ranging from packaging to consumer goods.

Products we can offer

| Product name | PET Plastic Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

- 0.7mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM