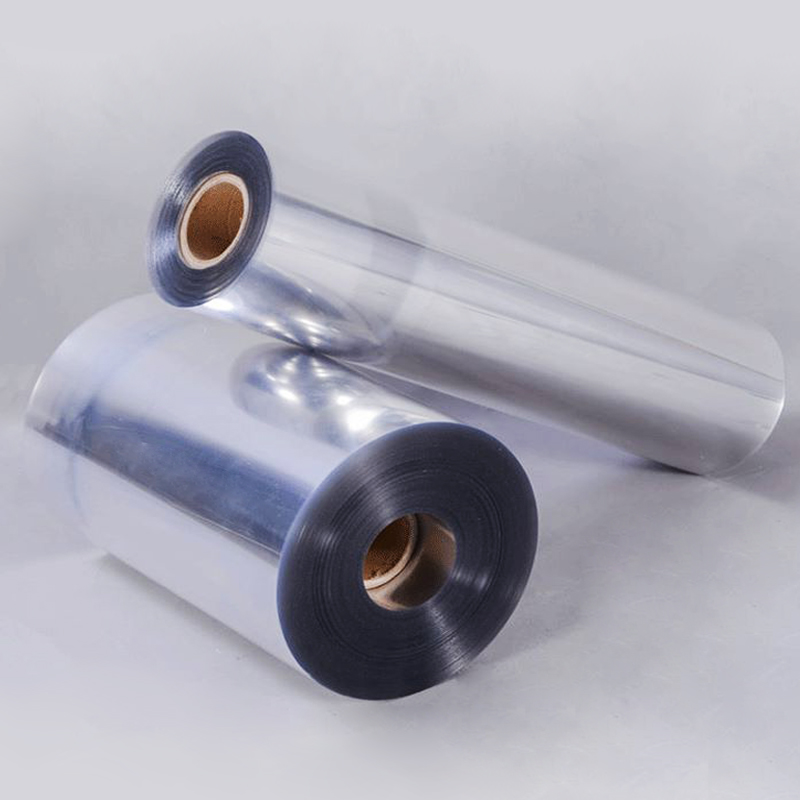

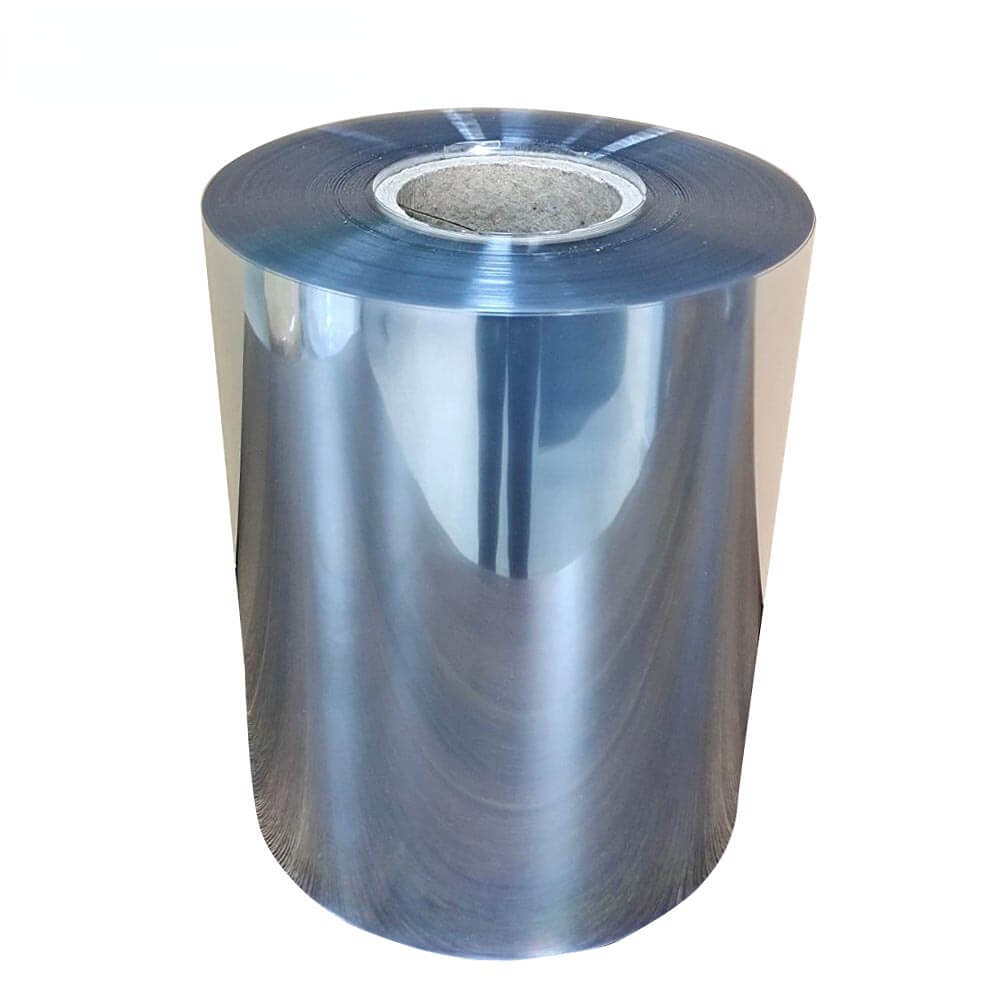

0.5 mm PET plastic rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

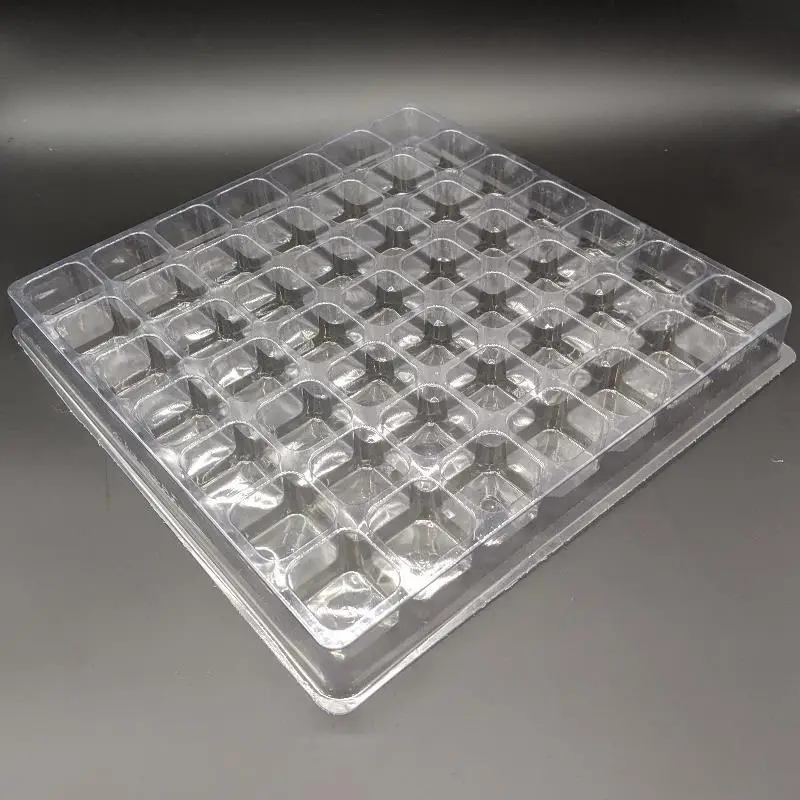

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "0.5 mm PET plastic rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction: 0.5 mm PET Plastic Rolls

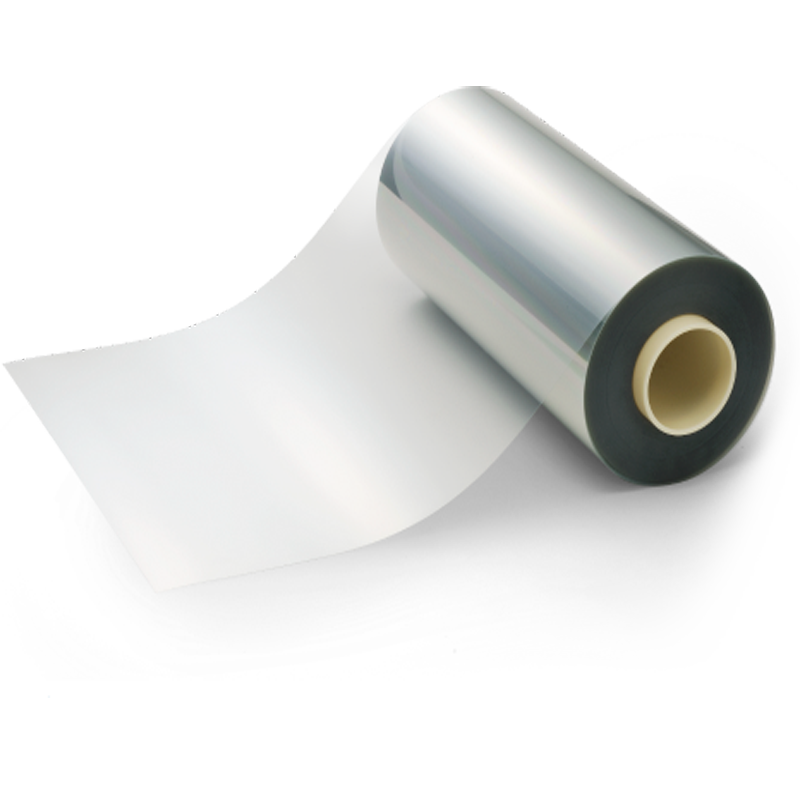

Our 0.5 mm PET (Polyethylene Terephthalate) plastic rolls are high quality, versatile materials designed for a wide range of applications, especially in thermoforming, blister packaging, and various other packaging solutions.

With excellent clarity, durability, and rigidity, these rolls provide the perfect balance of strength and flexibility for efficient and reliable packaging.

Key Features of 0.5 mm PET Plastic Rolls

1. Durability and Strength

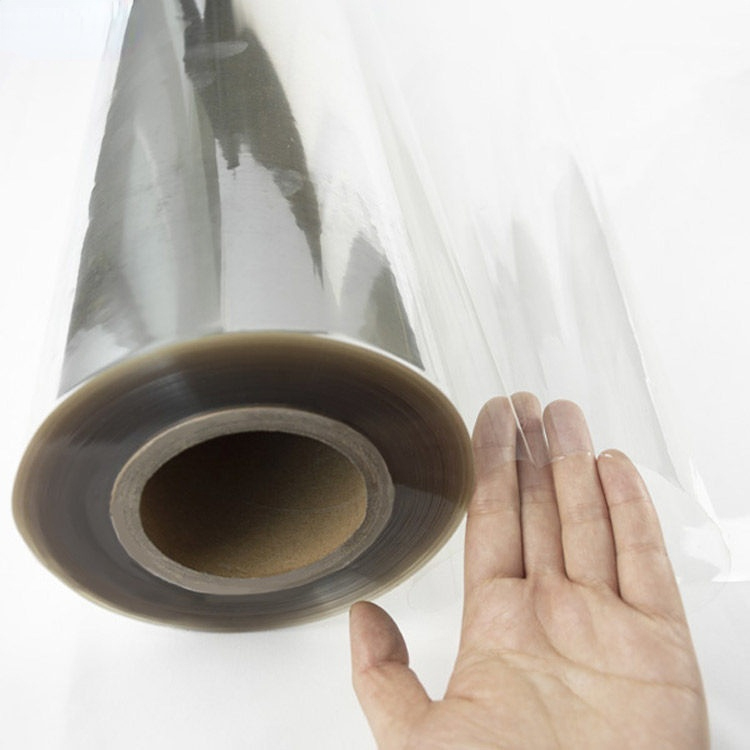

0.5 mm PET rolls are highly durable and resistant to breakage, ensuring long-lasting performance.

Excellent mechanical properties that provide a high degree of rigidity and resistance to deformation during use.

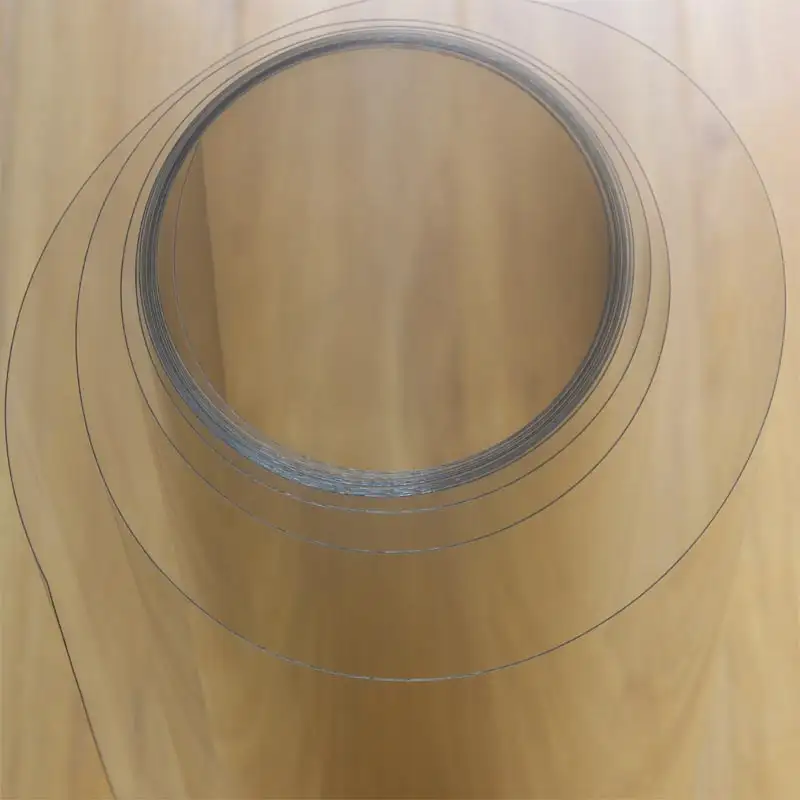

2. Clarity and Transparency

Exceptional optical clarity and gloss, allowing for superior product visibility.

Ideal for packaging products that require both protection and display appeal.

3. Chemical Resistance

PET offers excellent resistance to oils, greases, and various chemicals, ensuring your products remain safe and well-protected from external elements.

4. Environmental Friendly

PET is 100% recyclable, making it a more sustainable choice compared to other plastics. It contributes to reducing environmental impact and supports green initiatives.

5. Lightweight

The lightweight nature of PET helps reduce overall shipping costs and environmental footprint.

6. Thermoforming and Blister Packaging:

Suitable for high-quality thermoforming processes, allowing precise and consistent results.

Excellent for blister packaging, providing a secure and protective barrier for products.

7. Food Safety

Compliant with international food safety standards and regulations (e.g., FDA, EU), making it a safe choice for food packaging applications.

Applications of 0.5 mm PET Plastic Rolls

Thermoforming and Vacuum Forming: Ideal for creating rigid packaging, trays, and containers for various products.

Blister Packaging: Perfect for products such as pharmaceuticals, electronics, and consumer goods that require secure and visible packaging.

Food Packaging: Widely used for packaging fresh produce, snacks, and other food items that need clarity and durability.

Cosmetic Packaging: Used in the cosmetic industry to package products like makeup, skincare items, and fragrances due to its superior aesthetic qualities.

Parameter of 0.5 mm PET Plastic Rolls

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.5mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Customization: Our 0.5 mm PET plastic rolls can be customized in terms of size, color, and specific properties to meet your exact requirements. We offer a wide range of thicknesses and finishes to suit different applications.

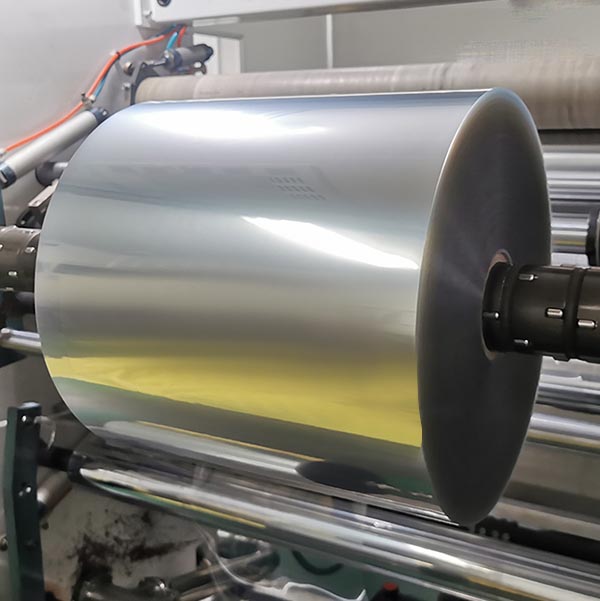

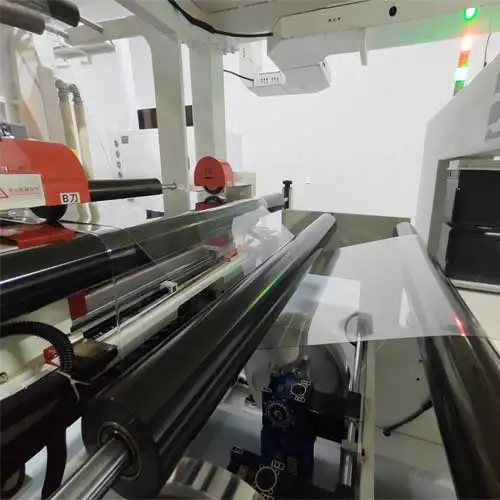

Production process of 0.5 mm PET Plastic Rolls

The production process of 0.5mm PET (Polyethylene terephthalate) plastic rolls typically involves several steps. Here’s an overview of the production process:

1. Polymerization: The process starts with the polymerization of raw materials. In this step, terephthalic acid and ethylene glycol are reacted to produce PET pellets or granules.

2. Extrusion: The PET pellets are then fed into an extruder, where they are melted at a high temperature and pressure to form a uniform molten mass.

3. Sheet Formation: The molten PET is extruded through a flat die to create a continuous thin sheet of plastic. This sheet is initially hot and flexible.

4. Cooling: As the extruded sheet comes out of the die, it passes through a cooling system, such as a series of chilled rollers or air-cooling units, to rapidly cool and solidify the plastic.

5. Sheet Thickness Control: To achieve the desired thickness of 0.5mm, the sheet goes through a series of gauge rolls or calibration units that precisely control the thickness of the plastic.

6. Solidification: After the sheet is cooled and its thickness is controlled, it becomes solid and semi-rigid.

7. Trimming and Cutting: The solidified sheet is trimmed to remove any uneven edges or irregularities and then cut into standard sizes, typically in rolls or sheets.

8. Surface Treatment (Optional): Depending on the application, the PET plastic rolls may undergo surface treatment to enhance adhesion, printability, or other specific characteristics.

9. Quality Control: Throughout the production process, quality control checks are performed to ensure that the PET plastic rolls meet the required specifications, including thickness, dimensions, and physical properties.

10. Packaging and Storage: Once the PET plastic rolls pass quality checks, they are packaged and stored properly to prevent damage or contamination until they are ready for distribution and use.

Why Choose Our 0.5 mm PET Plastic Rolls?

Reliable Quality: Manufactured using state-of-the-art technology, ensuring consistency and high-quality performance.

Global Delivery: With a robust supply chain, we offer reliable and on-time deliveries across various regions.

Customization Options: Tailored to fit your specific needs in terms of dimensions, colors, and performance.

Environmental Responsibility: Our products are recyclable, aligning with sustainable packaging practices.

For more information or to request a sample, feel free to contact us!

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- High Quality PET Plastic Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- UV-resistant PET Sheet Rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

- ESD PET Plastic Rolls

- Lightweight PET Plastic Rolls

- 1.2 mm PET plastic rolls

- Factory Price PET plastic rolls

- Wholesale Clear PET plastic rolls

- 1.8 mm Thickness PET Plastic Rolls

- Wholesale Conductive PET Plastic Rolls

- Wholesale PET plastic sheet rolls

- 1.5 mm Pet plastic sheet roll

- Transparent Rigid PET Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM