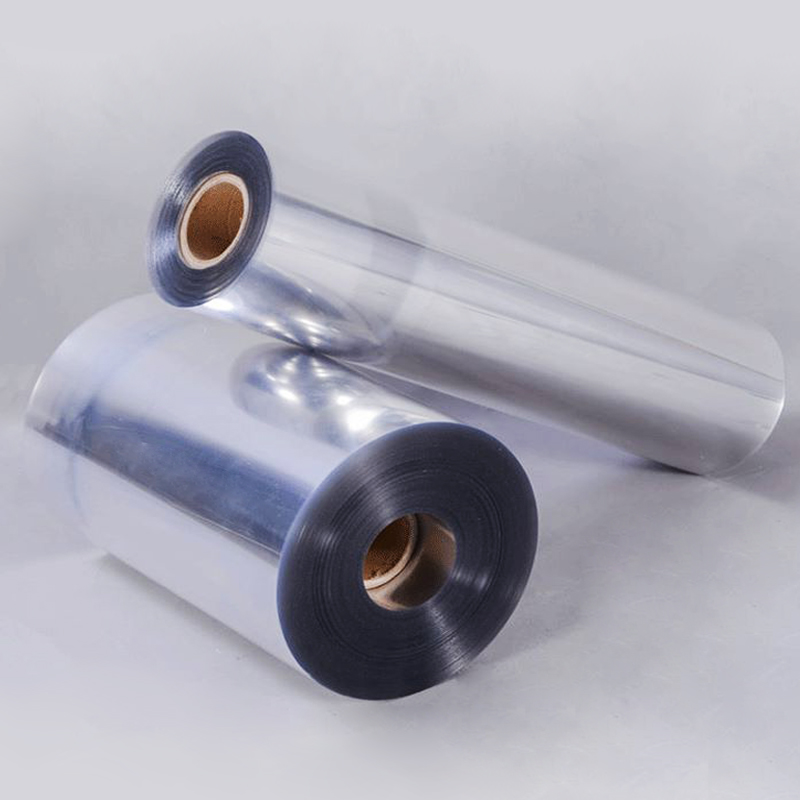

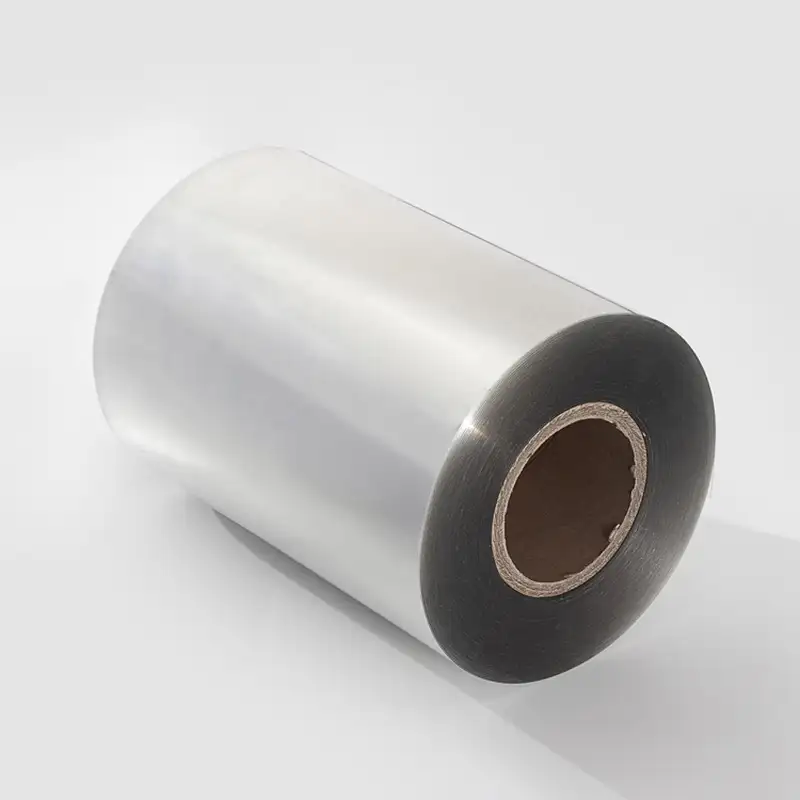

0.8mm PET plastic sheet rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? . pet-sheet.com is A factory focus on Manufacturer and Export rigid for thermoforming or blister packaging. As to "0.8mm PET plastic sheet rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction of 0.8mm PET plastic sheet rolls

0.8mm PET plastic sheet rolls are made from high-quality Polyethylene Terephthalate (PET), offering excellent durability, clarity, and resistance to chemicals and environmental factors. With a thickness of 0.8mm, these sheets are ideal for a wide range of applications in industries such thermoforming, electronics, food, automotive packaging.

Key Features of 0.8mm PET plastic sheet rolls

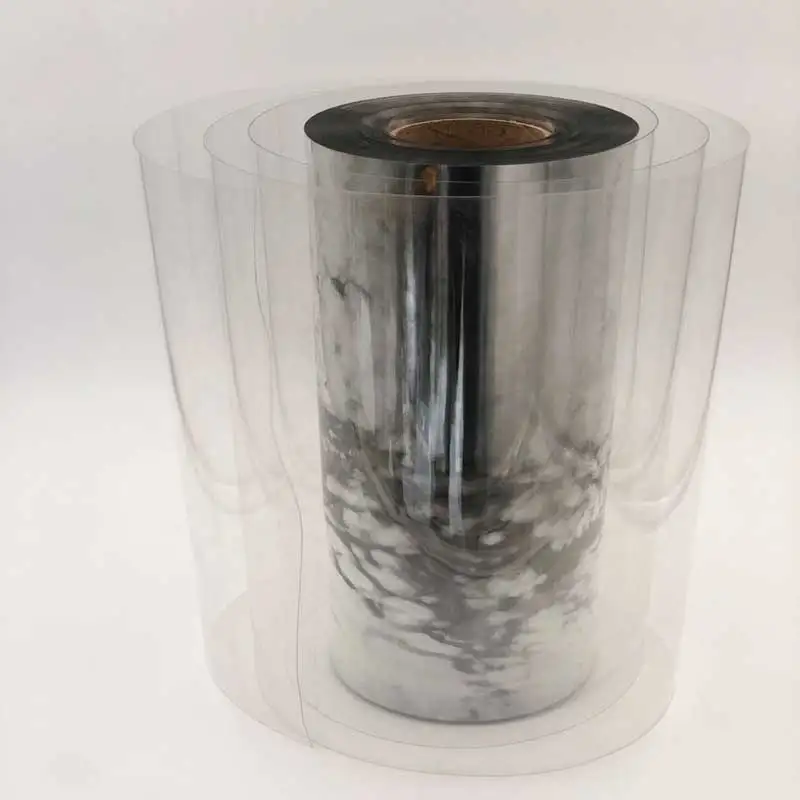

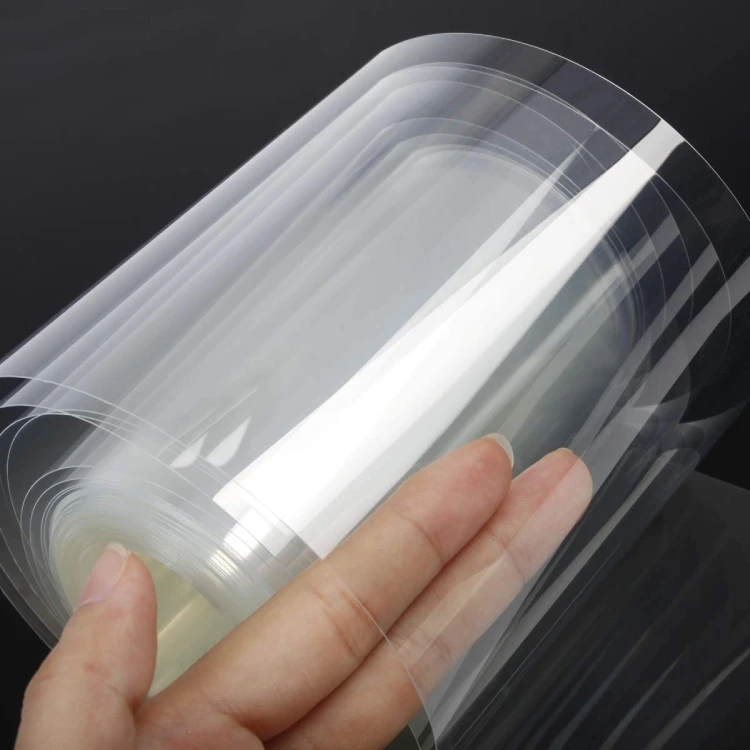

1. High Clarity & Transparency: PET sheets provide outstanding clarity, making them an ideal choice for applications that require transparency and visual appeal.

2. Strength & Durability: With a thickness of 0.8mm, these sheets offer a balance of rigidity and flexibility, ensuring both strength and resistance to wear and tear.

3. Chemical Resistance: PET is known for its resistance to chemicals, making it suitable for packaging food and beverages, as well as for use in industrial environments.

4. Heat Resistance: PET has a high melting point, allowing it to maintain its shape and integrity even in high-temperature environments.

5. Lightweight: Despite its strength, PET sheets are lightweight, which helps reduce shipping costs and handling difficulties.

6. Environmentally Friendly: PET is fully recyclable, making it an eco-friendly choice for businesses looking to reduce their environmental footprint.

7. Easy to Fabricate: The sheets can be easily cut, shaped, and thermoformed into custom designs for a variety of purposes.

Applications of 0.8mm PET plastic sheet rolls

0.8mm PET plastic sheet rolls are suitable for packaging products such us:

- Food packaging (such as snacks, candies, and ready-to-eat meals)

- Cosmetic packaging (for creams, lotions, and powders)

- Electronics packaging (for small electronic devices or parts)

- Medical device packaging

- Gift and retail packaging (boxes, displays, etc.)

- Pharmaceutical packaging

Product Parameter of 0.8mm PET plastic sheet rolls

| Product name | 0.8mm PET plastic sheet rolls, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- High Quality PET Plastic Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- Recycled PET Plastic Sheet Rolls

- UV-resistant PET Sheet Rolls

- 0.5 mm PET plastic rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

- 0.3mm Clear PET Sheet Roll

- ESD PET Plastic Rolls

- Lightweight PET Plastic Rolls

- 1.2 mm PET plastic rolls

- Factory Price PET plastic rolls

- Wholesale Clear PET plastic rolls

- 1.8 mm Thickness PET Plastic Rolls

- Wholesale Conductive PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM