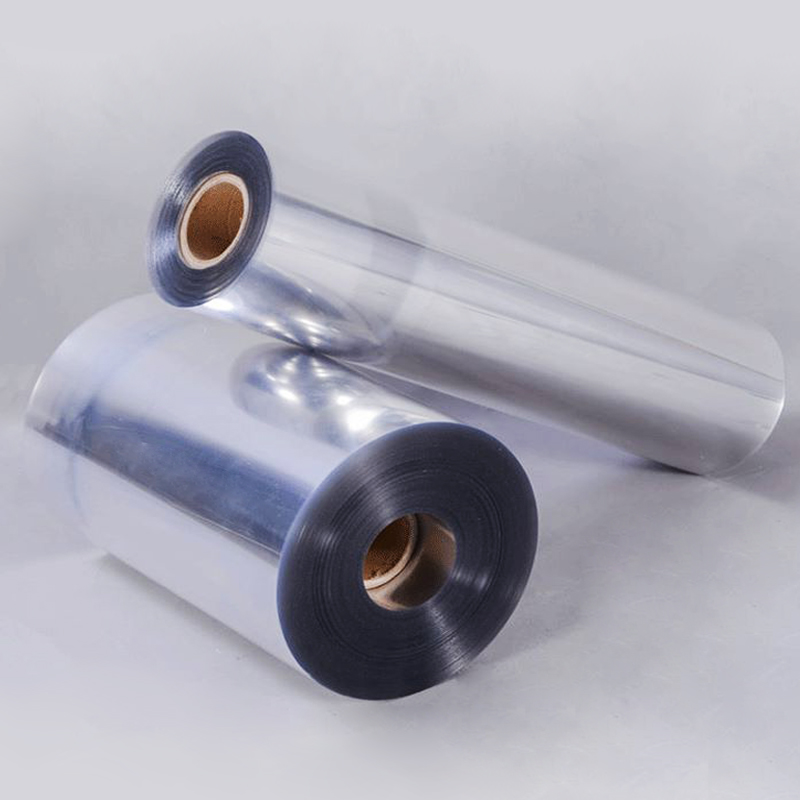

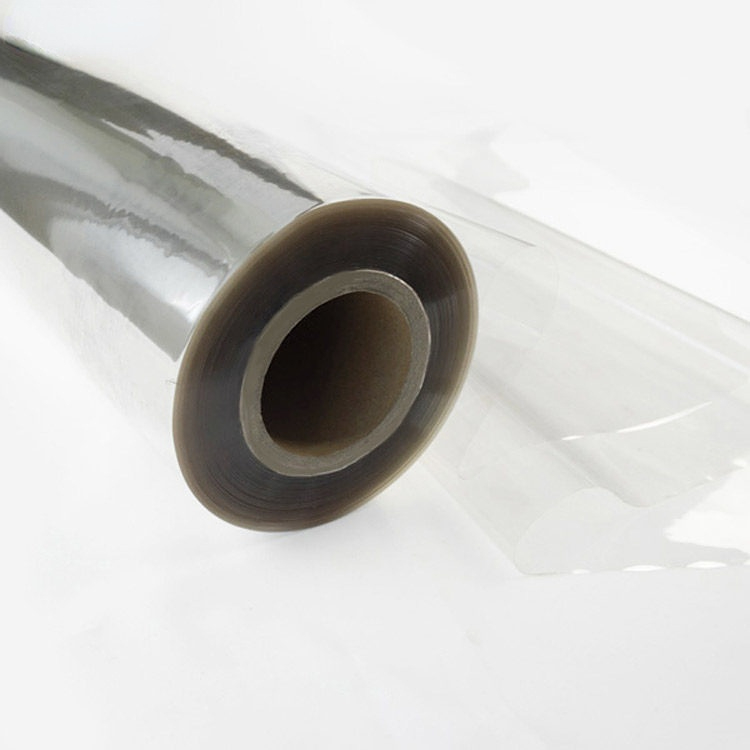

Coated PET Sheet Roll

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

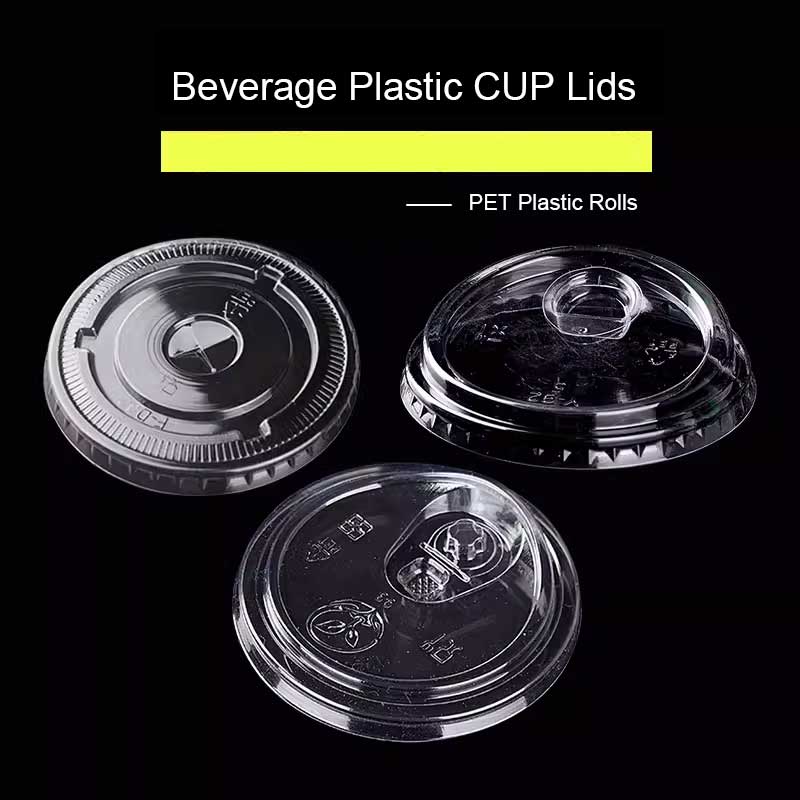

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? . pet-sheet.com is A factory focus on Manufacturer and Export rigid for thermoforming or blister packaging. As to "Coated PET Sheet Roll", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of Coated PET Sheet Roll

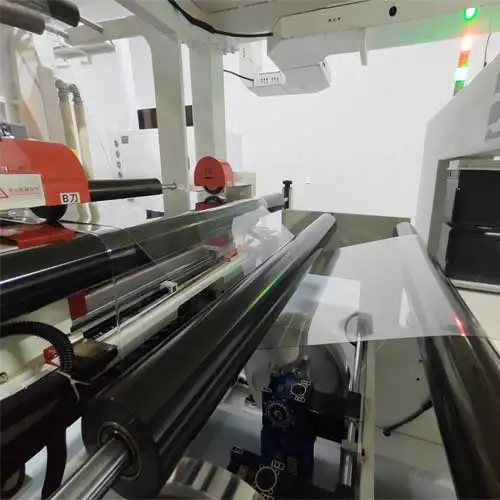

Coated PET sheet rolls refer to products in which a special coating is applied to the surface of polyester (PET) film. This coating can enhance the film’s abrasion resistance, UV protection, and adhesion properties, making it commonly used in packaging, labels, and various industrial applications.

Characteristic

1. Excellent aroma protection

2. Excellent gas (oxygen, nitrogen, carbon dioxide) barrier

3. Superior mechanical strength

4. Superior printability

Key Features of Coated PET sheet rolls

1. Material Composition: Made from polyethylene terephthalate (PET), known for its strength and lightweight properties.

2. Coating: The surface can be coated with different materials for enhanced properties, such as UV protection, anti-fogging, or adhesive properties.

3. Thickness: Available in various thicknesses to suit specific applications, typically ranging from 0.1 mm to 1.0 mm.

4. Transparency: High clarity and transparency, making it suitable for applications where visual appeal is important.

5. Chemical Resistance: Offers good resistance to a variety of chemicals, making it suitable for food packaging and industrial uses.

Application of Coated PET sheet rolls

Coated PET sheet rolls can be used in a variety of product packaging, including food packaging, pharmaceutical packaging, electronic product packaging, cosmetic packaging, and label and label materials. Their wear resistance and transparency make them particularly suitable for applications that require high strength and visual appeal.

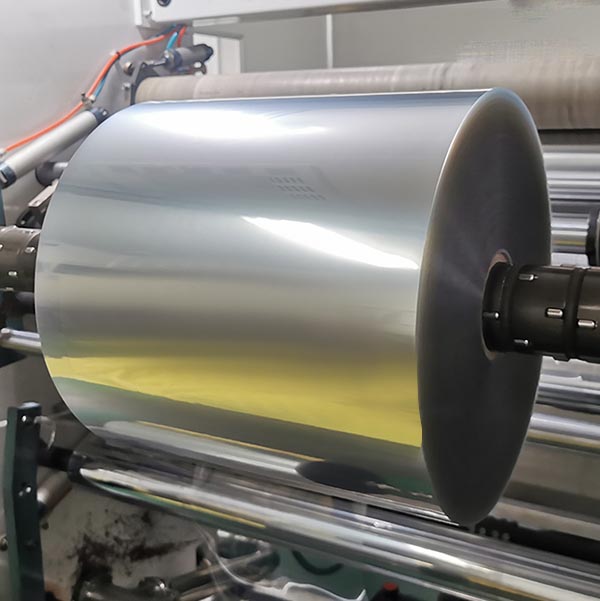

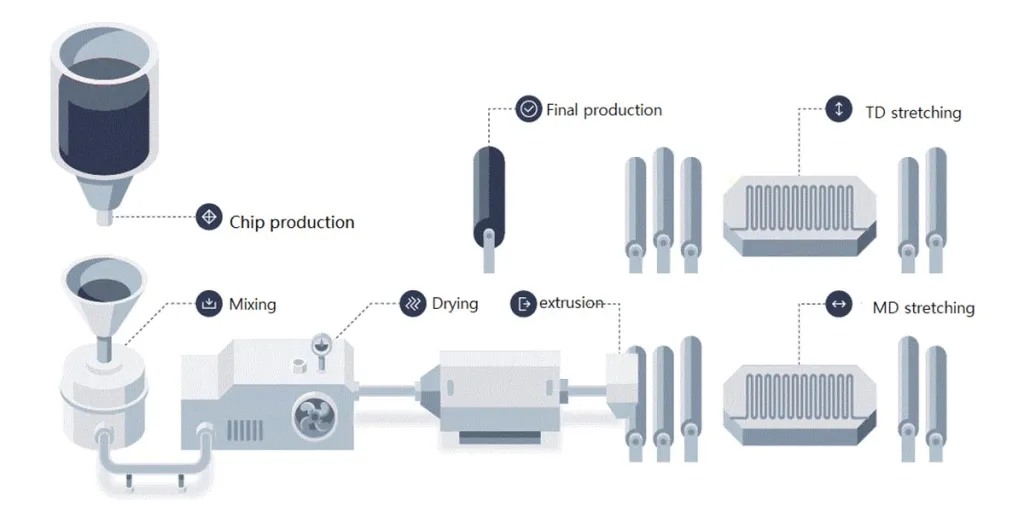

Production process of Coated PET sheet rolls

1. Raw Material Preparation: High-quality PET resin is used as the primary material to ensure stable product performance.

2. Extrusion Formation: The PET resin is heated and melted, then extruded through an extruder to form a film. This process ensures uniform thickness and quality of the film.

3. Cooling and Shaping: The extruded film passes through a cooling device to quickly solidify and maintain its shape.

4. Coating Treatment: The cooled PET plastic sheet enters the coating equipment, where a specific polymer or adhesive is evenly applied to enhance moisture resistance, gloss, or other properties.

5. Secondary Cooling: After coating, the film goes through a cooling system again to solidify the coating and ensure strong adhesion.

6. Winding and Cutting: The cooled Coated PET sheet rolls is wound into rolls and then cut into different specifications based on customer requirements.

7. Quality Inspection: Strict quality checks are conducted during and after production to ensure each roll meets standards.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- High Quality PET Plastic Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- Recycled PET Plastic Sheet Rolls

- UV-resistant PET Sheet Rolls

- 0.5 mm PET plastic rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

- 0.3mm Clear PET Sheet Roll

- ESD PET Plastic Rolls

- Lightweight PET Plastic Rolls

- 1.2 mm PET plastic rolls

- Factory Price PET plastic rolls

- Wholesale Clear PET plastic rolls

- 1.8 mm Thickness PET Plastic Rolls

- Wholesale Conductive PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM