ESD Antistatic PET Sheet Roll

ESD Antistatic PET Sheet RollPet-sheet.com (Desu Plastic) is a very top Manufacturer & factory of in China. We have advanced technology & equipment, lot of export and international trade experience. Free samples, OEM & ODM accepted

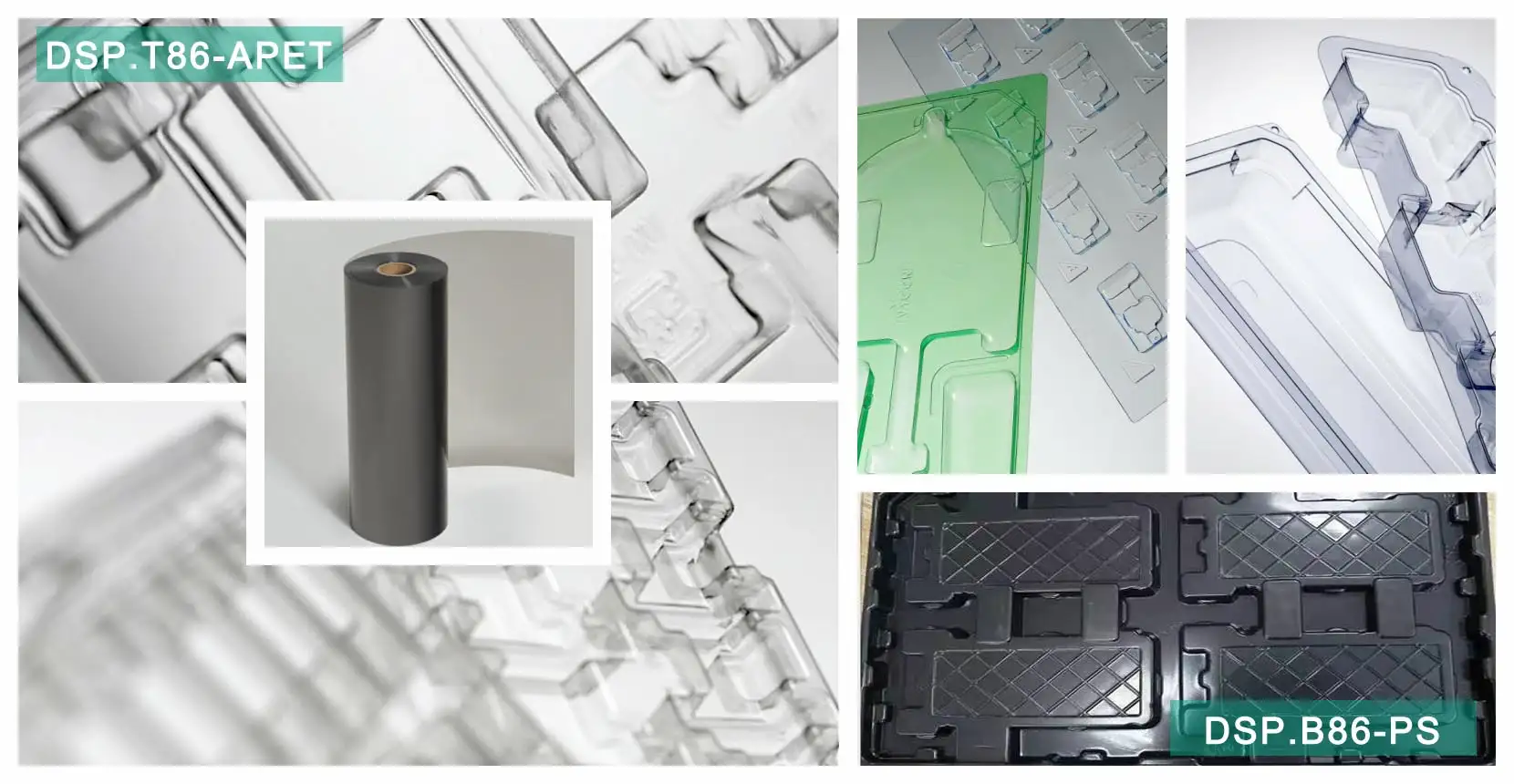

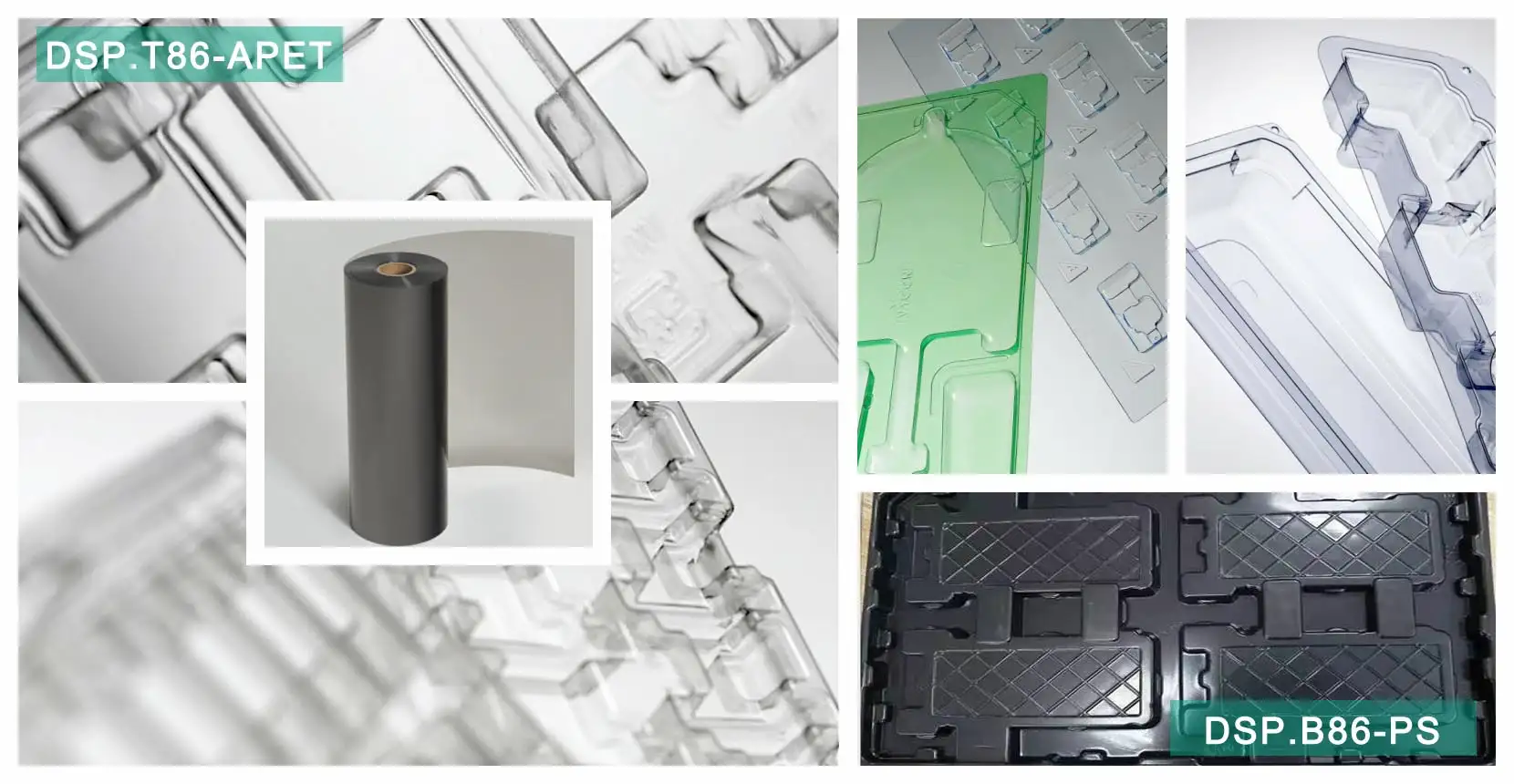

| Product Name: | ESD Antistatic PET Sheet Roll |

| Manufacturer: | pet-sheet.com(Desu Shanghai) |

| Production Process: | Multilayer Co-Extrusion Squeeze Out |

| Specification: | Size: 300-1400mm (PET); Thickness: 0.18-1.8mm; Packaging: Maximum 150kg/roll; Color: Clear/Transparent/Black/White/Custom Colors |

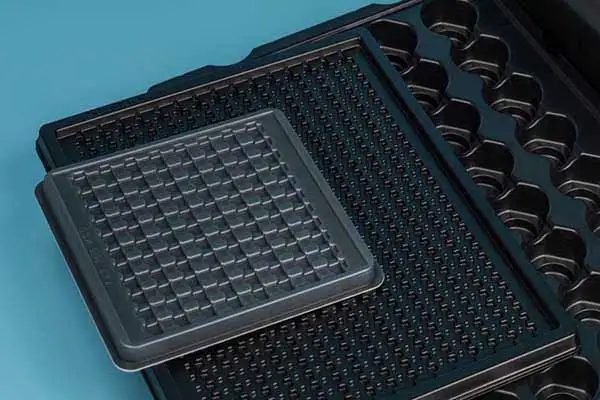

| Main Applications: | Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging |

| MOQ: | 5 tons (free sample accepted ) |

+8615800766301

Main Product From pet-sheet.com

What Is ESD Anti-static PET

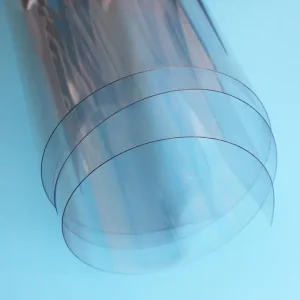

AntiStatic Apet Sheet is the Apet Sheet with Antistatic treatment which can be used for electronics and medical electronics packaging applications.

Antis tatic rate is 10e3~10e12. The surface is smooth and with good separating performance from the moulds. Built-in and coating types are 2 kinds of ESD technology different from the processing way. The former is processed by adding active material while producing, and the latter is by coating active agent to make end products with different grades of anti static functions, Anti static performance can be sustained for more than one year.

ESD (electrostatic discharge) Materials DATA

| Material | Surface resistance (Ω/sq) | Characteristic |

| Conductive | 103 to 105 | Conductive materials have low resistance, so electrons can easily flow through the surface or inside of these materials. The charge will flow to the ground or another conductive object in contact with the material. |

| Static dissipation | 105 to 109 | Compared with conductive materials, static dissipative materials can make charge flow to the ground or other conductors in a more controlled and slow manner. |

| Anti-static | 109 to 1012 | Anti-static materials can inhibit friction and electricity generation. |

Pet-sheet.com(Desu)’s Coated Technology

A roll of substrate (e.g. PP, PET, PS, etc.) is first coated with a coating device to coat the substrate, then dried to remove the solvent, and finally wound up into a roll for use as a finished or semi-finished product, although this coating technique is relatively simple (we call it the traditional coating method).

Desu Tech focuses on Extrusion Coating to develop related businesses, the unit price of products derived from such technology is at least $50 per square meter, and even some of them can be more than $3,000 per square meter, which is very different from traditional coated products, these substrates are mainly used in the precision electronics industry, and the coating technology occupies about 35% of key technologies.

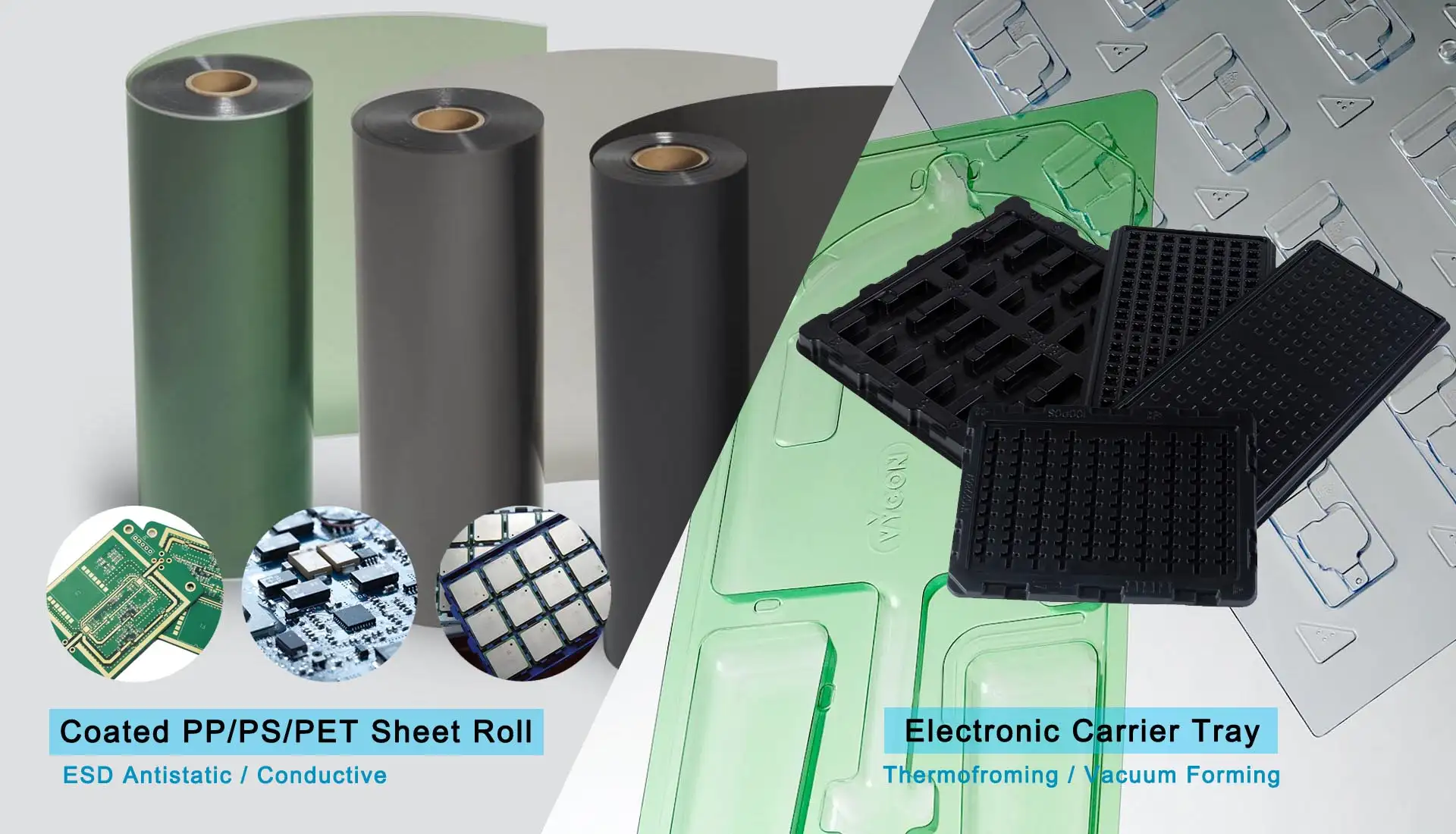

Desu Tech has exclusive coating technology to enable PP/PS/PET sheet has special feature like anti-static, conductive, heat-sealing, high-barrier. that is Desu Tech’s strength to provide high-level Coated PP/PS/PET sheet roll as material to production carrier tray for electronic components manufacturer; The appearance of the sheet is black and translucent, permanent conductive, dust-proof, and ultra-high cleanliness; super wearresistance (No dust removal/generated in the standard friction test over 3000 times, effectively avoiding the dust that might generated in the friction between the fray parts and the fray during transportation as to reduce the possibility of secondary pollution on the parts carrying in the forming, Meanwhile ensure no impact on ESD in friction); Superior water resistance (Durable to pure water ulfrasonic water washing ove 300 times without ESD degrading or fading); Strong alcohol wiping resistance (ESD performance won’t be Fading);

Antistatic/Conductive Function Products

Sheets with conductive and antistatic properties are often used in production halls for precision machinery or in the electrical and electronic industry. Main Applications: Electronics, Optical and Medical Industries. Desu Tech focuses on Extrusion Coating to develop related businesses, the unit price of products derived from such technology is at least $50 per square meter, and even some of them can be more than $3,000 per square meter, which is very different from traditional coated products, these substrates are mainly used in the precision electronics industry, and the coating technology occupies about 35% of key technologies.

- ESD Antistatic

- Resistance Value: 10e6~10e9

- Features: Ultra-clean, translucent, washable, friction resistant, alcohol resistant

- ESD Performance: 2~4 years

- Conductive Dissipasive

- Resistance Value: 10e4~10e6

- Features: Ultra-clean, translucent, washable, friction resistant, alcohol resistant

- ESD Performance: permanent conductive

Main Coated PP PS PET Sheet Applications

The Coated Technology mainly used in Electronics, Optical and Medical Industries. To protects product from damage during transportation. Widely applied in therforming trays for precision electronic components with high requirements for conductivity durability and cleanliness, such as face ID module, camera lens and its components, FPC (flexible circuit board), PCB (printed circuit board), LCD module, chip, RF board, flash memory, modem, transceiver, baseband, high-precision sensor, etc.!

PET-SHEET.COM

PET-SHEET.COM