ESD PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

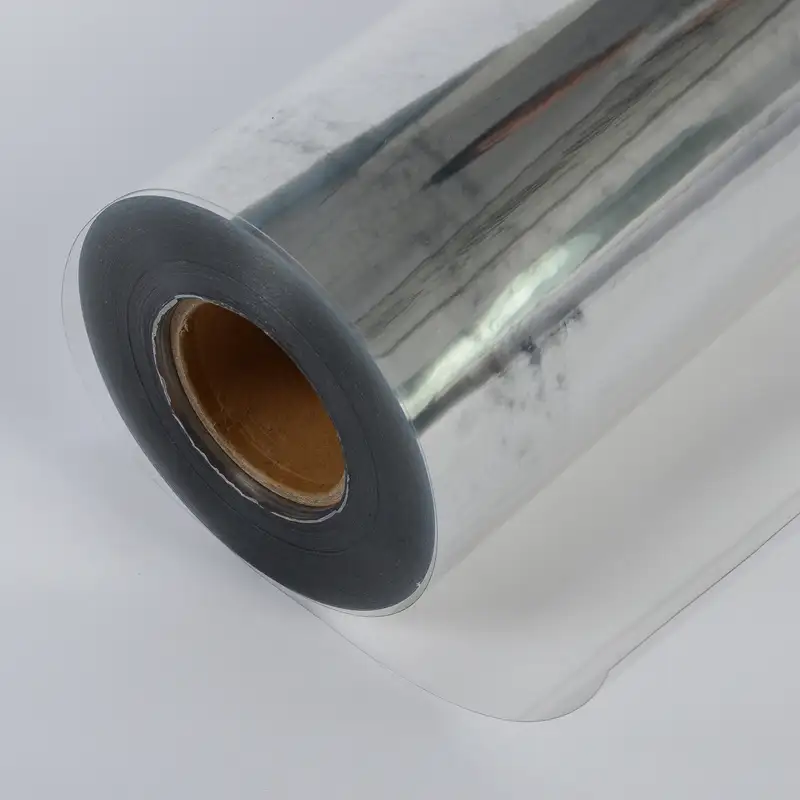

- Production Limits:

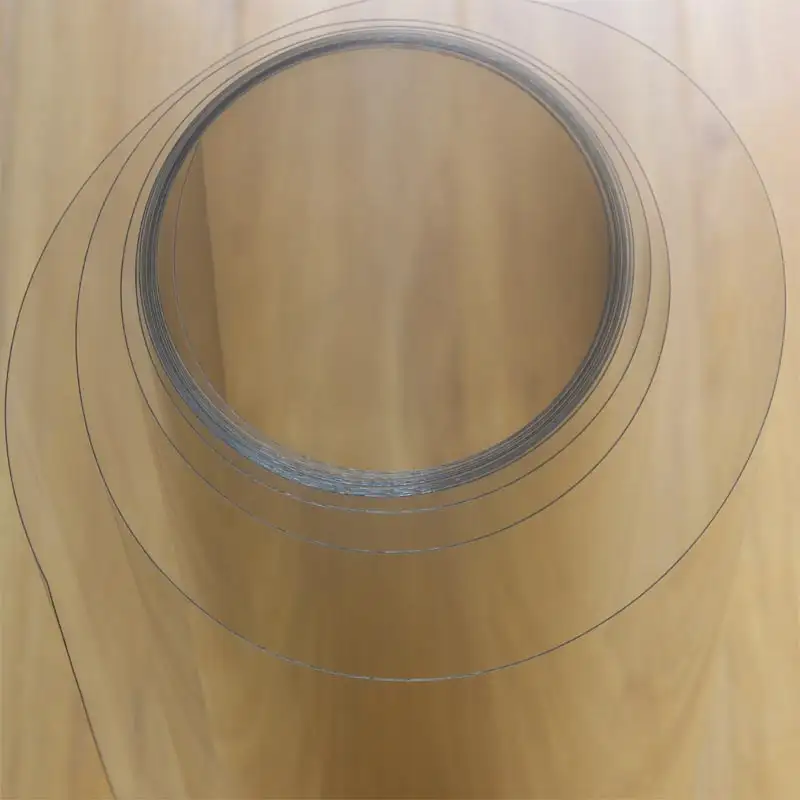

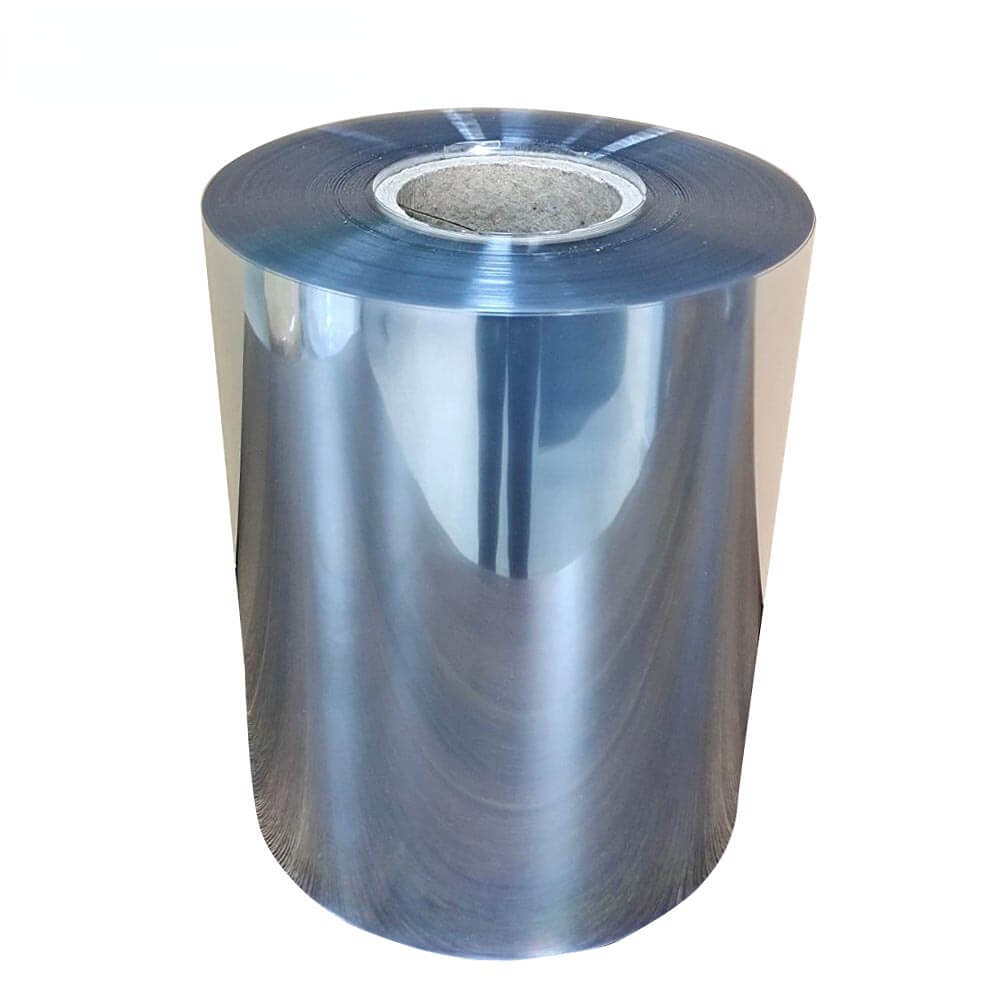

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "ESD PET Plastic Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of ESD PET Plastic Rolls

ESD PET Plastic Rolls (Electrostatic Discharge PET) are high performance, static-control plastic materials designed to protect sensitive electronic components from electrostatic discharge (ESD) during manufacturing, handling, and transportation.

Made from Polyethylene Terephthalate (PET), these plastic rolls are engineered with electrostatic dissipative (ESD) properties, making them essential in industries where static electricity can cause significant damage to delicate electronic components, such as circuit boards, microchips, semiconductors, and other sensitive electronic devices.

What is ESD Plastic PET?

ESD Plastic PET is a type of Polyethylene Terephthalate (PET) plastic that has been specially modified to offer electrostatic dissipation. Unlike regular PET, which is an insulating material, ESD PET has been treated or coated with conductive elements that allow static charges to be safely dissipated into the environment, preventing the buildup of harmful static electricity. The material provides a safe and reliable solution for the protection of sensitive components against electrostatic discharge (ESD), which could potentially compromise their functionality or cause permanent damage.

Key Features and Benefits of ESD PET Plastic Rolls

1. Effective ESD Protection

The primary advantage of ESD PET plastic rolls is their ability to dissipate static charges, providing protection against electrostatic discharge. This is especially important in industries where even small amounts of static electricity can cause damage to sensitive components like PCBs (Printed Circuit Boards), microchips, and semiconductors.

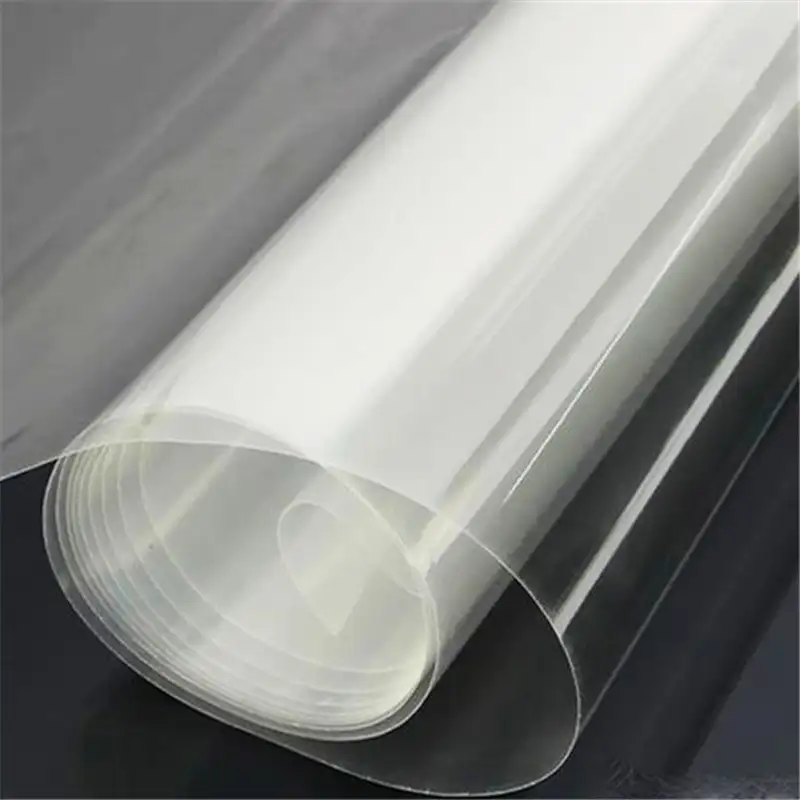

2. High Durability and Strength

PET is known for its strength and durability. ESD PET plastic rolls are tough, flexible, and resistant to tearing, making them suitable for packaging and transporting electronic parts that require protection. PET is also resistant to wear and aging, ensuring long-term performance.

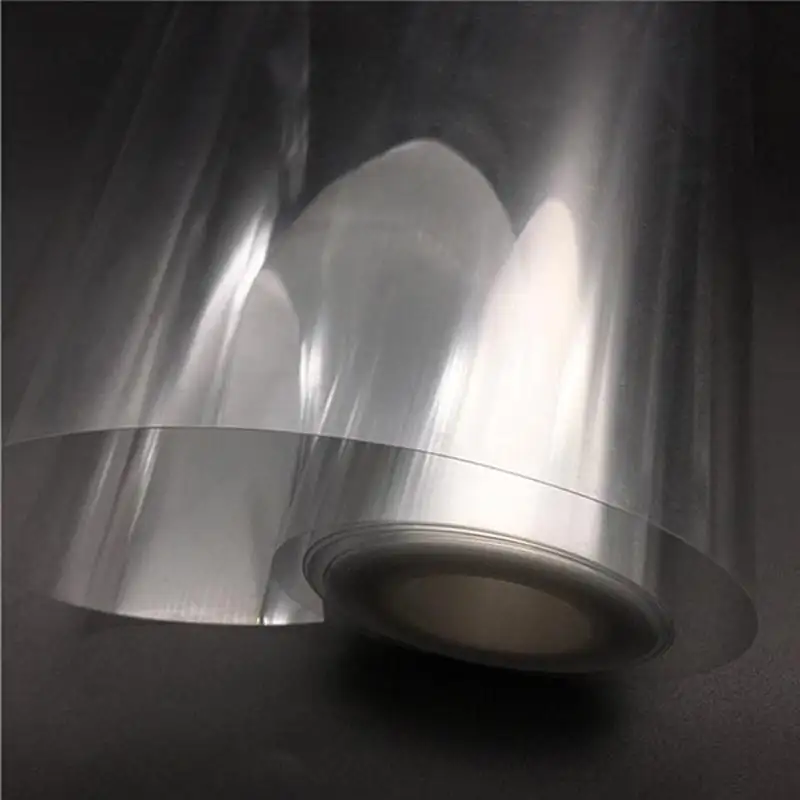

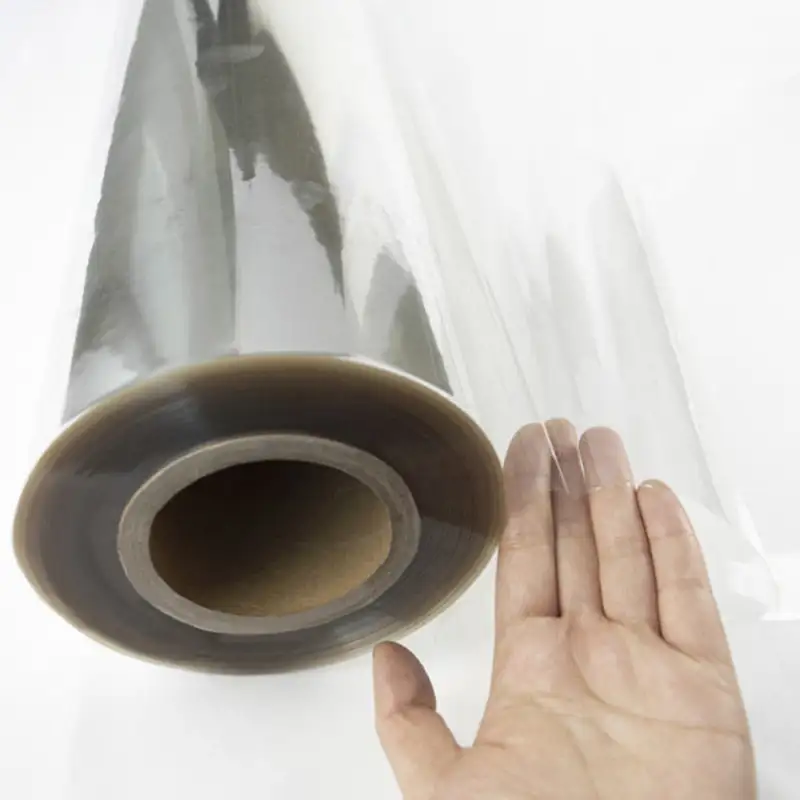

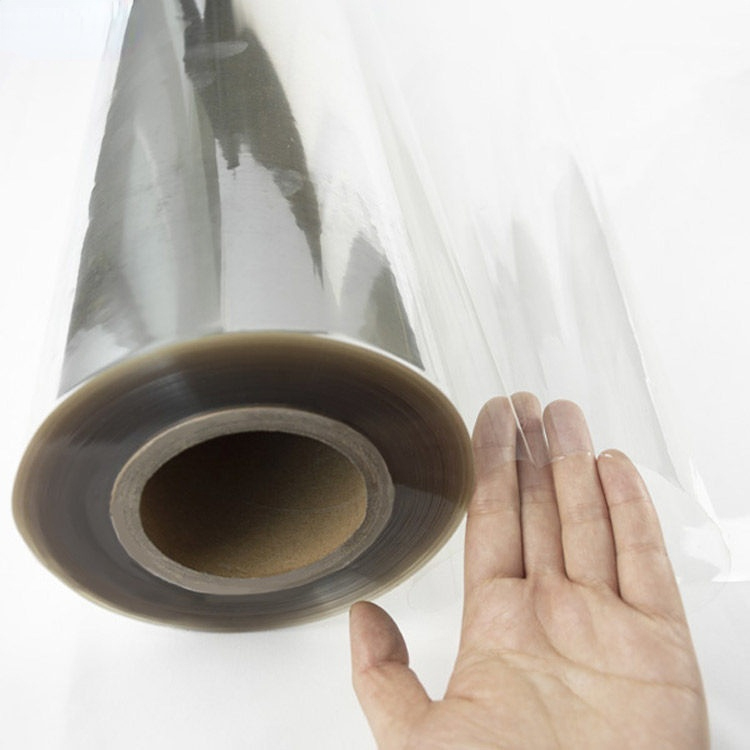

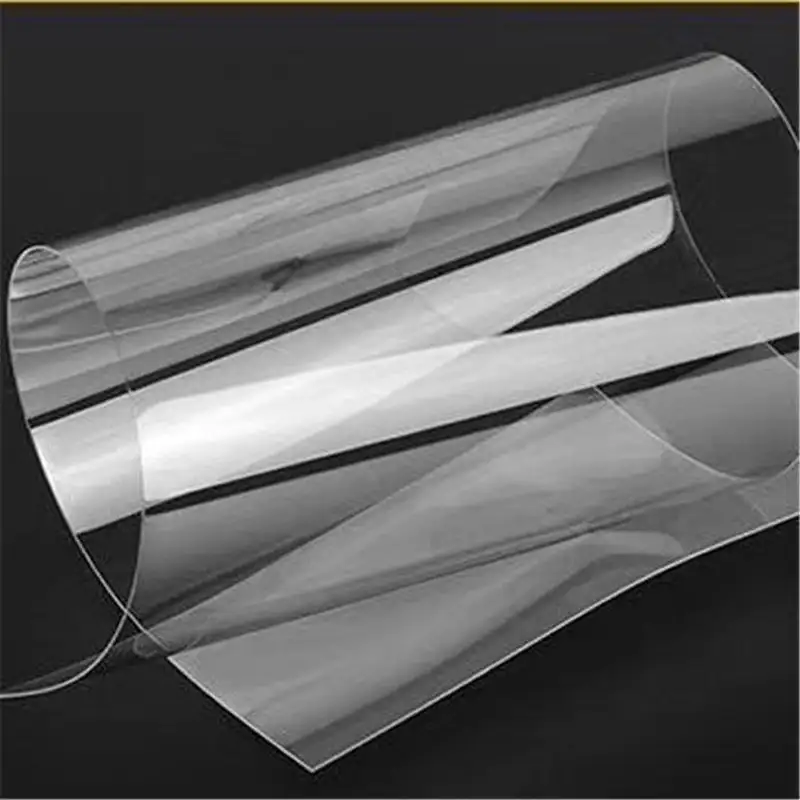

3. Clarity and Transparency

ESD PET plastic rolls offer excellent optical clarity, allowing for easy visual inspection of products packaged within. This is particularly beneficial for quality control in manufacturing environments, as operators can visually inspect parts without unboxing or disturbing the packaging.

4. Lightweight and Easy to Handle

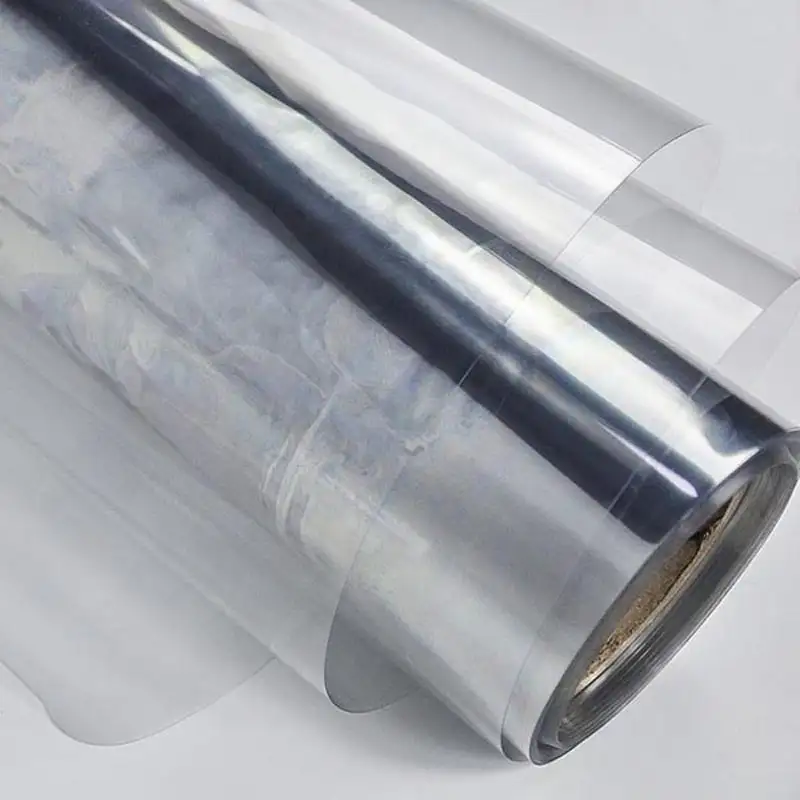

PET is a lightweight material, which reduces shipping and handling costs. ESD PET plastic rolls are easy to use in various packaging applications, including thermal forming, die-cutting, and wrapping, ensuring the efficient handling of electronic components during the packaging process.

5. Customizable for Specific Applications

ESD PET plastic rolls can be easily customized to suit specific needs, such as different thicknesses, widths, and lengths. This flexibility ensures that the material can be used across a wide range of applications in the electronics, automotive, medical, and other industries that require static-sensitive packaging.

6. Environmentally Friendly

PET is a recyclable material, making ESD PET plastic rolls an eco-friendly option for businesses looking to reduce their environmental impact. By using recyclable plastic, companies can contribute to sustainability goals and reduce waste in their operations.

7. Cost-Effective

ESD PET offers an affordable solution for ESD protection when compared to more expensive materials, such as conductive foams or bags. It provides reliable static protection at a reasonable cost, making it deal for both small and large-scale operations.

8. Non-Toxic and Safe for Use

Unlike some other static-control materials, ESD PET plastic roll is non-toxic and safe to handle, making it a user-friendly option for packaging and storage. It does not release harmful substances during use, making it suitable for a wide range of industries.

Applications of ESD PET Plastic Rolls

1. Electronic Component Packaging

ESD PET plastic rolls are primarily used to package static-sensitive electronic components like circuit boards, chips, displays, and batteries. The static-dissipative nature of the material helps protect these components from damage during storage, transport, and handling.

2. Thermoforming for Protective Trays

ESD PET is commonly used in thermoforming applications, where the material is heated and molded into protective trays for electronic parts. These trays provide an organized and secure way to store and transport components, reducing the risk of ESD-related damage.

3. Anti-Static Bags and Covers

ESD PET plastic rolls are used to create anti-static bags, covers, and films for products that need to be protected from electrostatic discharge. These bags are widely used in electronics assembly, testing, and shipping processes.

4. Medical Device Packaging

In the medical industry, where precision and quality are paramount, ESD PET plastic rolls are used to protect medical components that contain sensitive electronics, such as diagnostic equipment, sensors, and implantable devices, from ESD during the packaging and shipping process.

5. Automotive Electronics Packaging

With the increasing integration of electronics in vehicles, ESD PET plastic rolls are also used for packaging automotive electronic components, such as control modules, sensors, and wiring, ensuring that these parts are protected during transport and assembly.

ESD PET plastic rolls are a highly effective solution for protecting sensitive electronic components from electrostatic discharge, ensuring that parts remain undamaged during the manufacturing, storage, and shipping processes.

Offering a combination of static protection, durability, customizability, and environmental friendliness, ESD Pet plastic rolls are becoming the go-to material for electronic packaging applications. Whether used for thermoforming protective trays, anti-static bags, or component wraps, ESD PET plays a crucial role in safeguarding products across various industries, particularly those with high ESD sensitivity like electronics, automotive, and medical sectors.

Why Choose pet-sheet.com

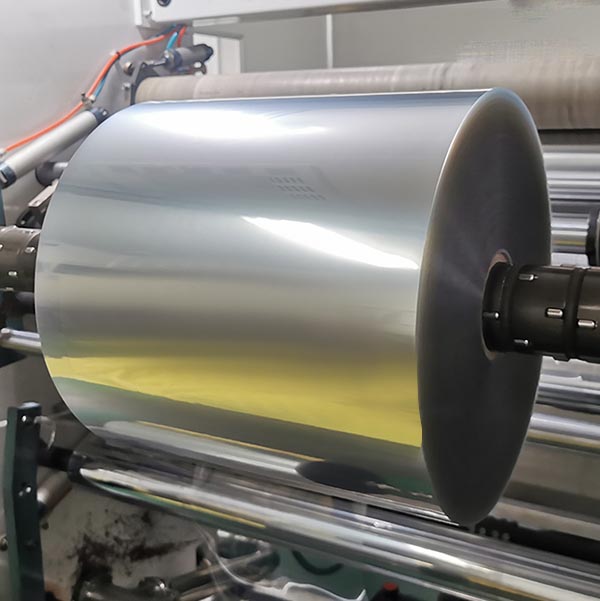

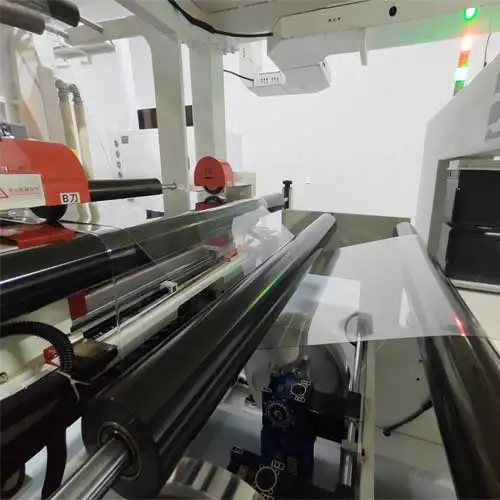

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

- 0.7mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM