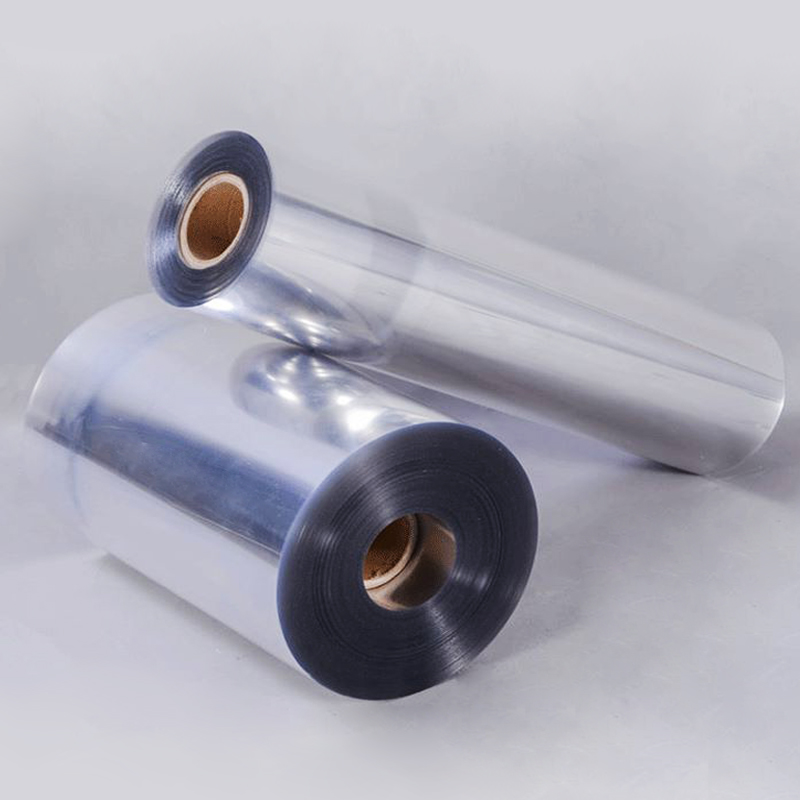

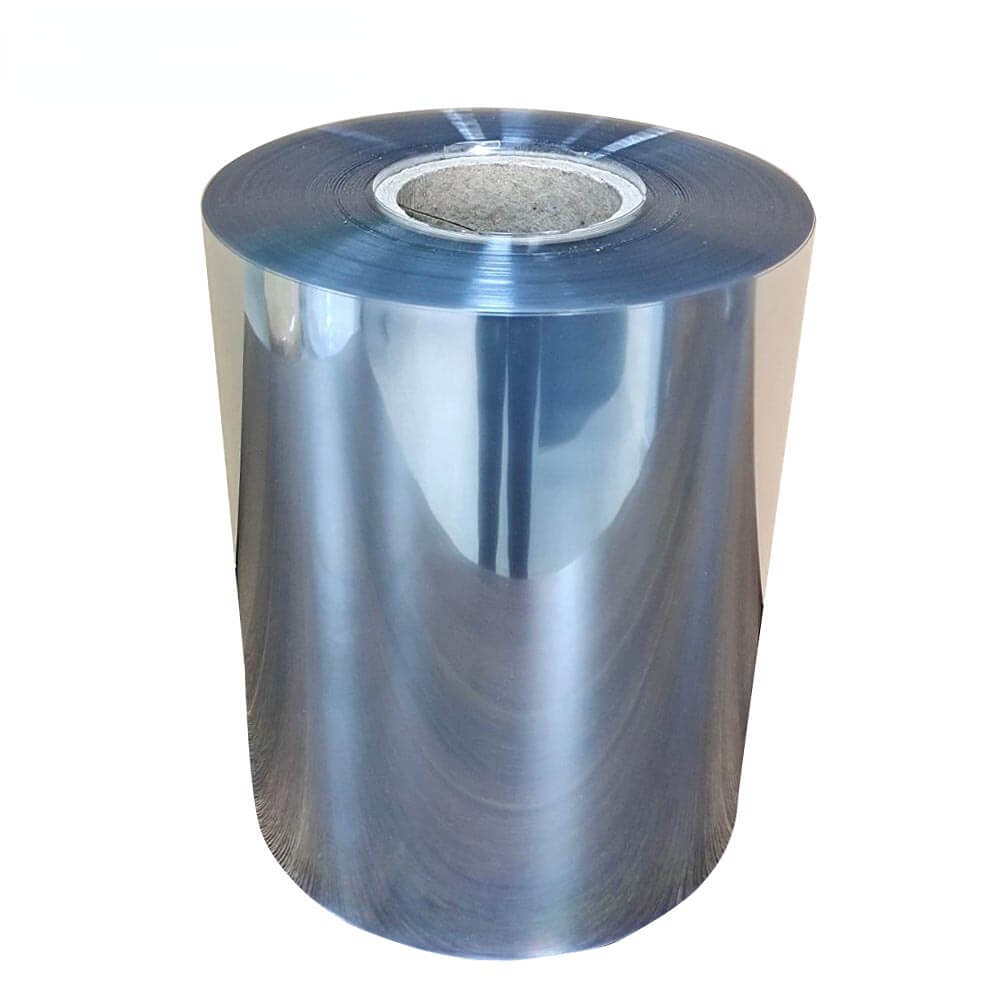

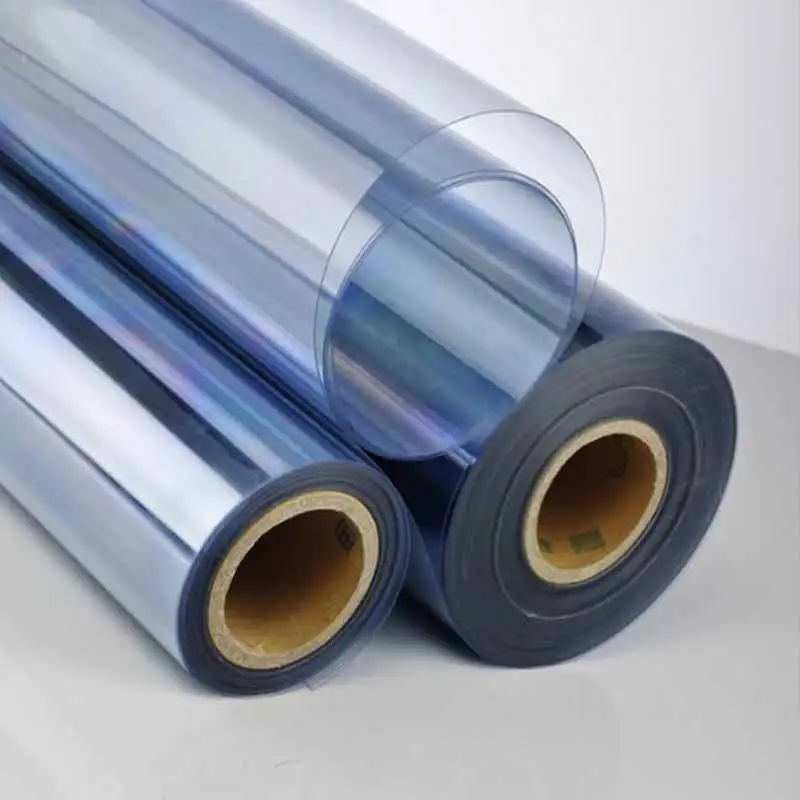

Factory Price PET plastic rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

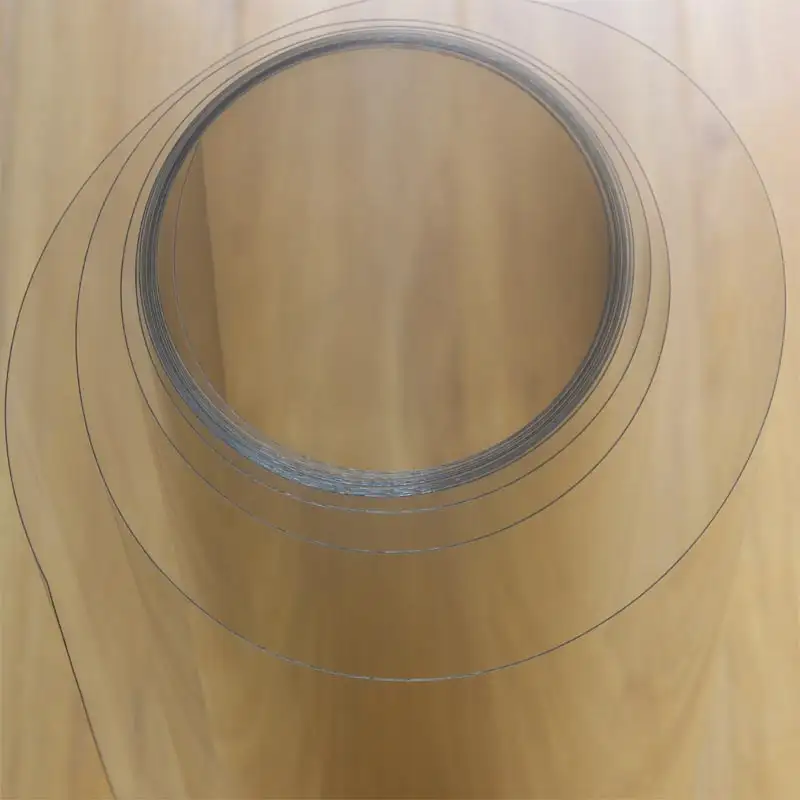

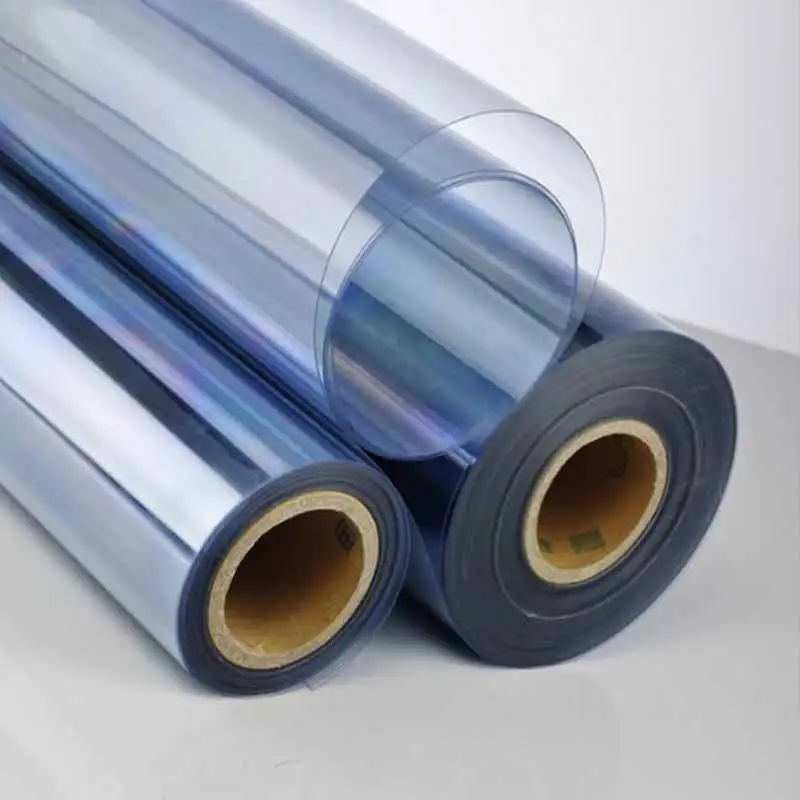

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "Factory Price PET plastic rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Factory Price PET Plastic Rolls Boost Sustainable Development in the Packaging Industry

As the demand for eco-friendly materials in the packaging industry continues to grow, PET plastic rolls (Polyethylene Terephthalate) have quickly become a market favorite due to their outstanding performance and sustainable properties. Recently, several leading manufacturers have launched Factory Price PET Plastic Rolls, offering cost-effective and versatile solutions to drive innovation across various industries.

Product Highlights: Eco-Friendly, High Performance, and Versatility

PET plastic rolls offer the following advantages, making them widely applicable in industries such as food, medical, and electronics:

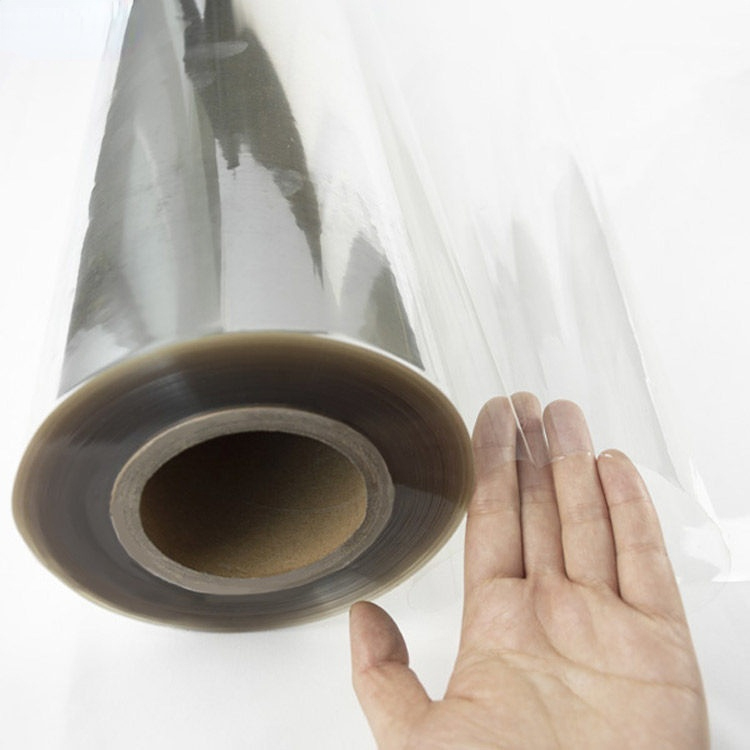

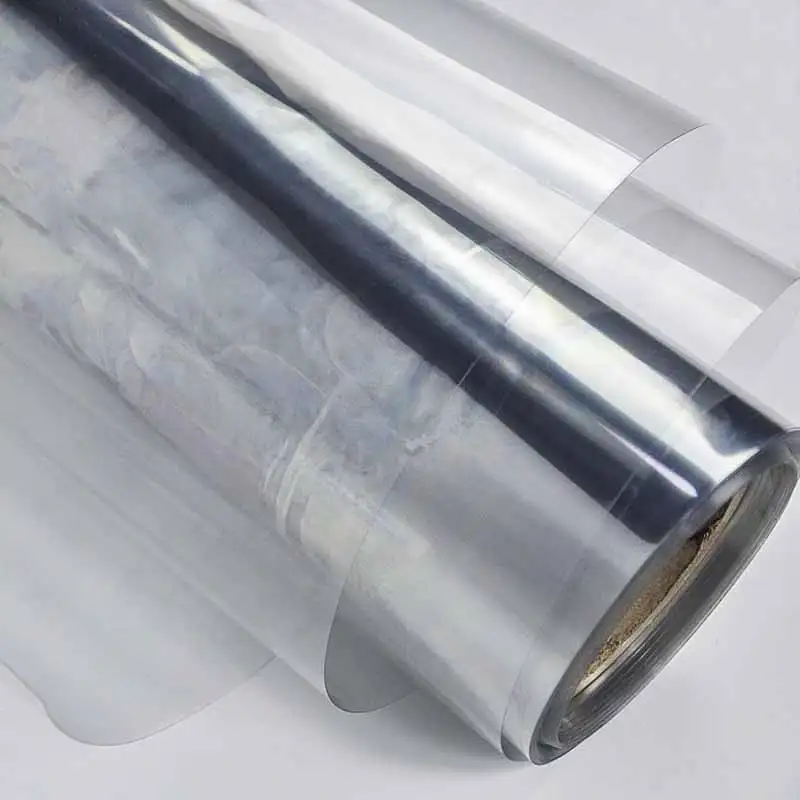

High Transparency: Ensures an attractive packaging appearance while showcasing product details.

Superior Strength: Excellent impact resistance and high durability, suitable for various transportation and storage environments.

Eco-Friendly and Recyclable: Complies with global environmental trends, supporting companies in achieving their sustainability goals.

Excellent Thermoforming Performance: Easy to process into various shapes, making it ideal for a wide range of packaging needs.

Price Advantage: Factory Direct Supply, Unbeatable Cost-Effectiveness

By offering a factory-direct supply model, Factory Price PET Plastic Rolls eliminate intermediaries, significantly reducing procurement costs. Additionally, the stable supply chain ensures that customers receive high-quality products on time.

Ideal Applications Across Multiple Industries

Food Packaging: Suitable(pet-sheet.com) for food trays, clear boxes, and blister packaging, ensuring safety and hygiene.

Medical Packaging: Used for disposable medical device packaging, meeting strict hygiene requirements.

Electronics Packaging: Protects delicate electronic components with excellent dust and moisture resistance.

Consumer Goods Packaging: Ideal for transparent casings for cosmetics and daily goods, enhancing brand image.

Driving the Future of Sustainable Development

Due to its eco-friendly features and superior performance, PET plastic rolls are becoming the future of the packaging industry. Factory Price PET Plastic Rolls, with their high cost-effectiveness, reliable quality, and flexible services, are leading businesses toward new heights in green packaging.

How to Choose Cost-Effective Factory Price PET Plastic Rolls?

As the demand for eco-friendly and high-performance materials continues to grow in the packaging industry, PET plastic rolls (Polyethylene Terephthalate) have become a popular choice in the market due to their outstanding transparency, strength, and recyclability. How can you select Factory Price PET Plastic Rolls that meet your needs while offering great value? Here are several key factors to help businesses make an informed decision.

Product Quality

Material Source: Ensure the PET plastic rolls use high-quality raw materials, preferably food-grade or materials that meet other industry standards. The quality of the raw material directly affects the stability and safety of the product.

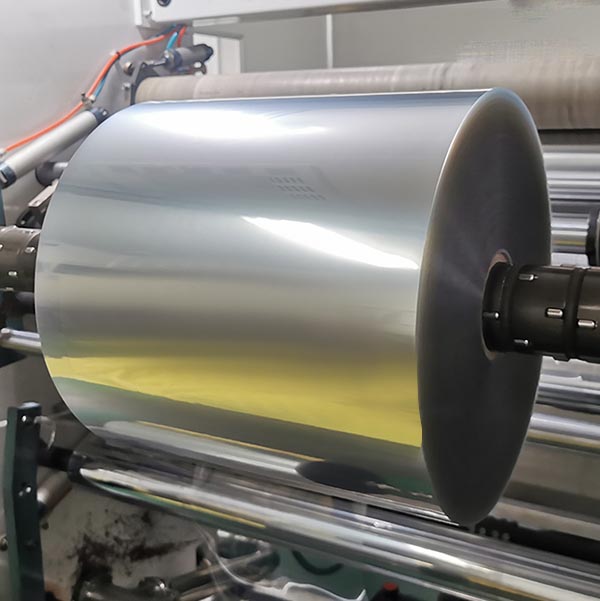

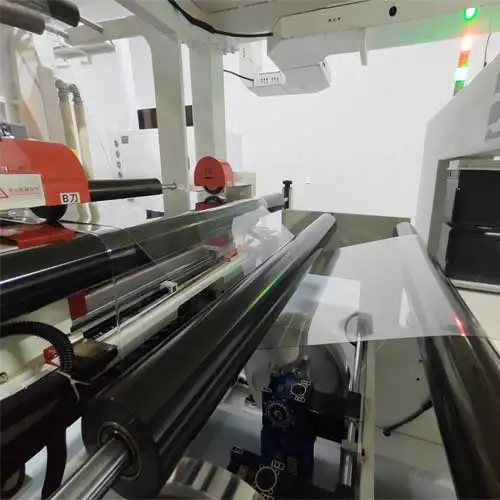

Production Process: Understand whether the production process complies with international standards. High-quality production processes ensure precision and consistency in molding, packaging, and other stages.

Test Reports: Choose manufacturers that provide testing reports or quality certifications to ensure the product meets physical and chemical performance standards (such as tensile strength, transparency, UV resistance, etc.).

Supplier Reputation and Stability

Factory Credentials: Choose manufacturers with ISO, CE, or other international certifications, which indicate they follow standardized quality control and environmental protection practices.

Delivery Lead Time: Ensure the supplier has stable production capabilities to deliver products on time and avoid delays that could impact your business.

Customer Reviews: Check customer reviews and case studies. Select suppliers with long-term customers and good reputations for reliability and quality.

Price and Cost-Effectiveness

Compare Prices: Obtain quotes from multiple suppliers and compare cost-effectiveness. Don’t rely solely on the lowest price—consider product quality and after-sales services as well.

Bulk Purchase Discounts: If placing a large order, negotiate for better pricing and additional services (such as shipping discounts or after-sales support).

Transparent Pricing: Ensure there are no hidden fees in the quotation. Understand additional costs, such as shipping, taxes, or customs duties, to avoid budget overruns.

After-Sales Service and Technical Support

After-Sales Support: Choose suppliers that provide after-sales support, such as return or exchange policies for defective products, or technical assistance during the product’s use.

Technical Consultation: Ensure the supplier can offer professional technical support if you have special requirements or need customized solutions to optimize your packaging.

Sample Testing and Evaluation

Samples Before Bulk Orders: Request samples before committing to bulk orders. Testing samples allows you to assess product quality, suitability, and manufacturing process.

Small Batch Orders: If possible, start with a small batch order to evaluate the supplier’s production capabilities and product quality before placing a large order.

Supply Chain Flexibility and Responsiveness

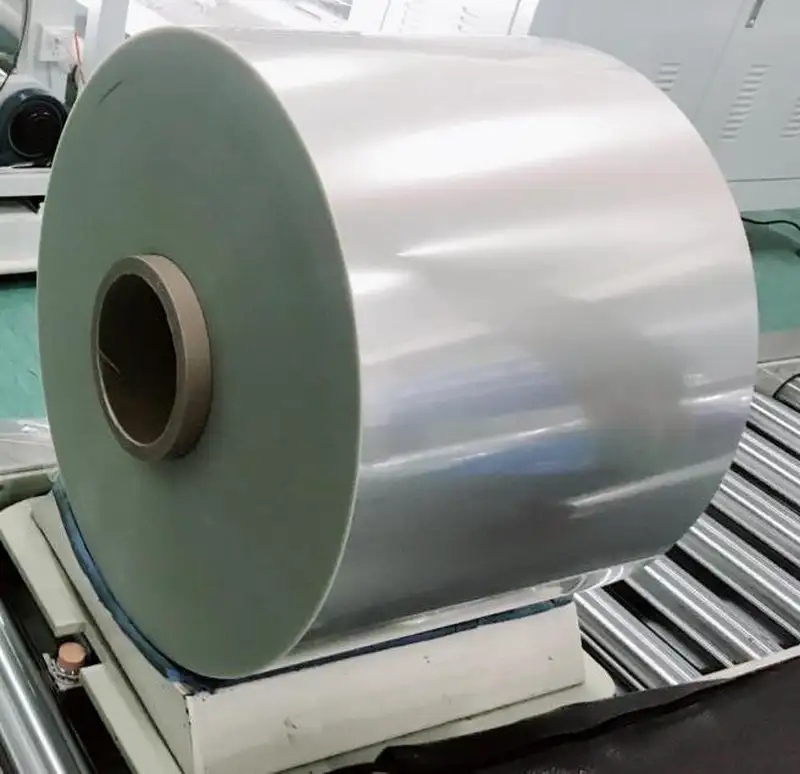

Inventory Management: High-quality suppliers usually maintain adequate stock, ensuring that your needs are met quickly and efficiently.

Global Logistics Support: If you require global sourcing, choose suppliers with experience in international logistics, which will ensure smooth transportation across borders.

By considering these factors comprehensively, you can select a PET plastic roll supplier that meets your needs while providing high cost-performance, stability, and efficient support for your production.

The reason to choose PET-sheet Factory Price PET Plastic Rolls lies in its high quality, reliable supply chain, and competitive pricing. As an experienced manufacturer, PET-sheet offers PET plastic rolls made from premium raw materials that meet industry standards, ensuring stability and safety in various packaging applications. Whether it’s transparency, tensile strength, or UV resistance, the products undergo rigorous testing to meet the diverse needs of customers. Additionally, with advanced manufacturing processes and a global logistics network, PET-sheet guarantees timely deliveries and offers flexible customization services, making it a trustworthy partner for your packaging solutions.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- High Quality PET Plastic Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- UV-resistant PET Sheet Rolls

- 0.5 mm PET plastic rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

- ESD PET Plastic Rolls

- Lightweight PET Plastic Rolls

- 1.2 mm PET plastic rolls

- Wholesale Clear PET plastic rolls

- 1.8 mm Thickness PET Plastic Rolls

- Wholesale Conductive PET Plastic Rolls

- Wholesale PET plastic sheet rolls

- 1.5 mm Pet plastic sheet roll

- Transparent Rigid PET Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM