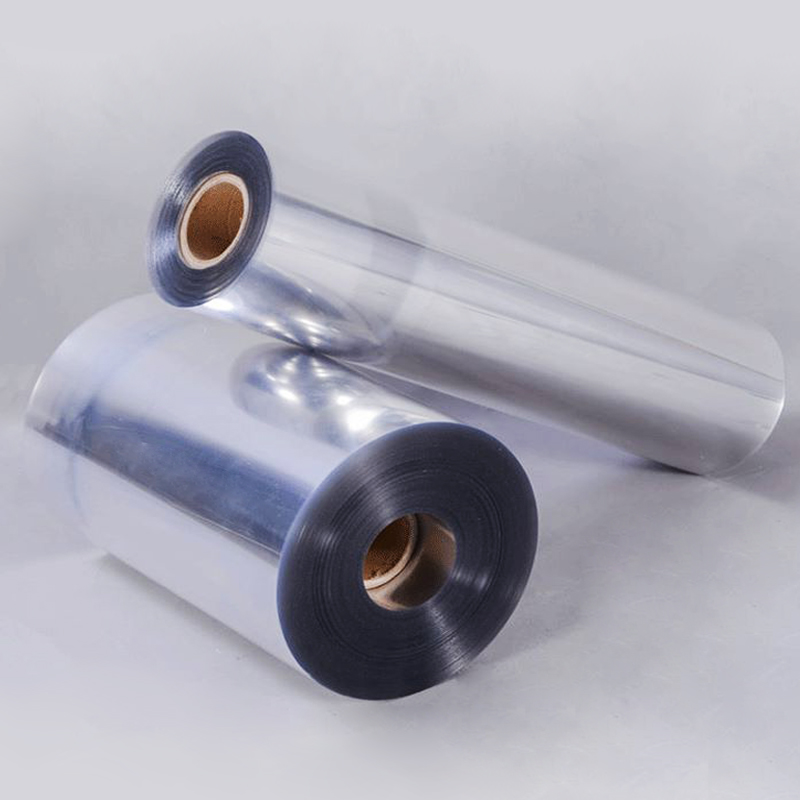

Flexible PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

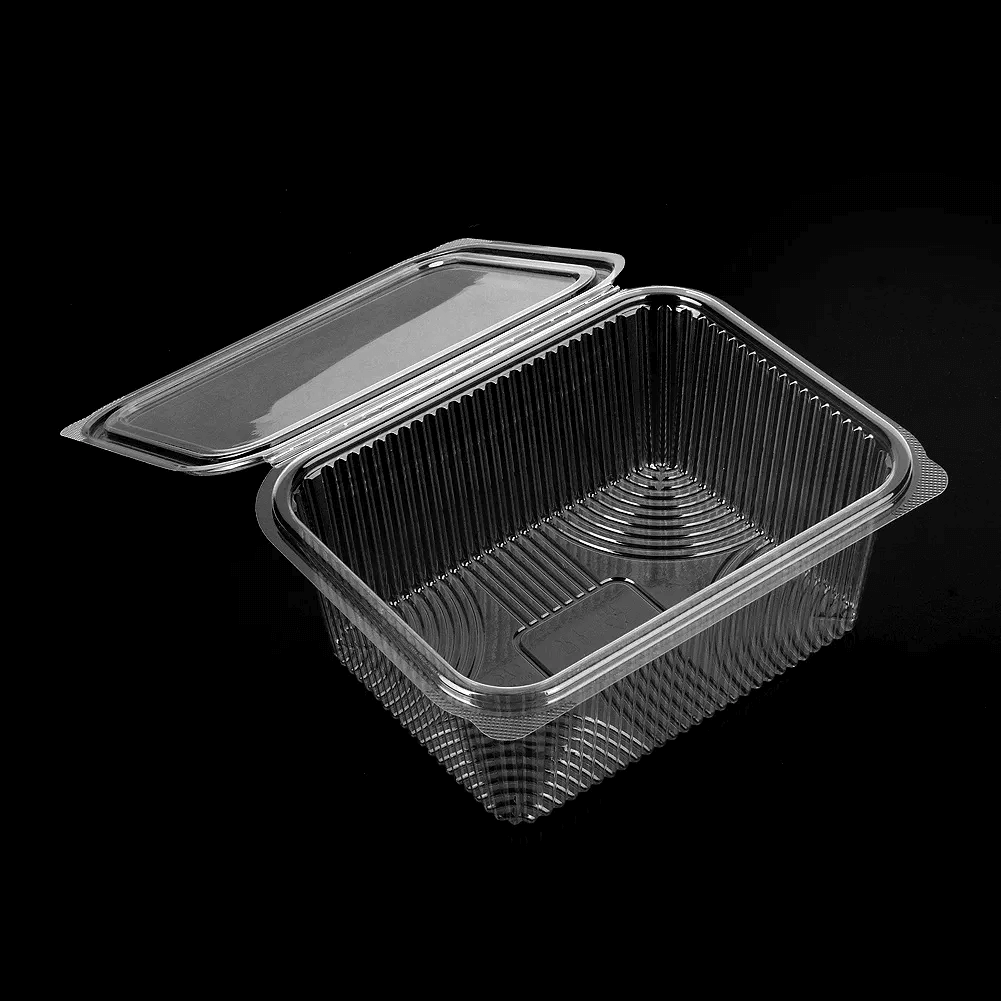

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "Flexible PET Plastic Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction: Flexible PET Plastic Rolls

Our flexible PET plastic rolls are high performance, versatile plastic film products that are widely used for packaging. Made of premium polyethylene terephthalate (PET) material, they feature excellent transparency, strength, flexibility, and durability, making them ideal for a variety of demanding product packaging.

Advantages of PET packaging plastic rolls

- High quality transparency ensures the best display of your products.

- Excellent molding performance supports a variety of molding and processing methods.

- Strong durability ensures the integrity of the product during transportation and storage.

- Customized services can provide customized services of different thicknesses, widths and roll lengths according to customer needs.

- Reliable supply chain to ensure timely delivery to meet global market needs.

Key Features of Flexible PET Plastic Rolls

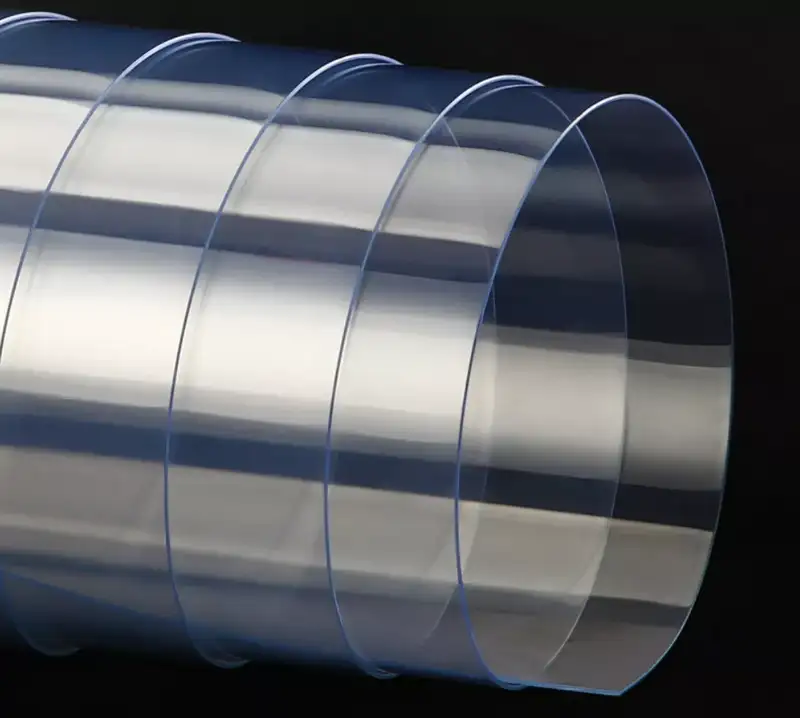

1. High Transparency and Gloss

As Clear Flexible PET Plastic Rolls, our products provide excellent optical clarity, showcasing packaged contents vividly while enhancing the overall aesthetic appeal.

2. Superior Mechanical Properties

These Flexible Plastic Rolls boast high tensile strength and tear resistance, ensuring they can withstand various stresses during processing and use, guaranteeing long-term stability.

3. Lightweight and Eco-Friendly

PET material is lightweight and recyclable, aligning with modern environmental standards and making it a sustainable choice for Flexible Packaging Material.

4. Chemical and Temperature Resistance

As Thermoplastic flexible PET plastic rolls, our products are resistant to a wide range of chemicals and high temperatures, making them suitable for diverse packing applications.

5. Versatile Applications

Whether it is PET packaging plastic rolls for food, pharmaceutical or electronic packaging or PET plastic films for lamination, our products meet every need.

6. Customization Options

Desu (pet-sheet.com) as a leading PET Plastic Roll Manufacturer, we offer customized solutions in various thicknesses, widths, and lengths to ensure our products perfectly match your specific requirements.

Application of Flexible PET Plastic Rolls

1. Food packaging: commonly used in fresh food, snacks and beverage packaging, which can keep the product fresh and extend the shelf life.

2. Industrial packaging: suitable for protective packaging of various electronic products, tools and equipment.

3. Pharmaceutical packaging: meets food and pharmaceutical packaging standards, providing safe and pollution-free packaging solutions for pharmaceuticals.

4. Transparent packaging materials: widely used in retail, consumer goods and other packaging designs that require visual appeal.

5. Thermoforming packaging: suitable for thermoforming production lines, which can quickly and accurately form various packaging containers.

Parameter of Flexible PET Plastic Rolls

| Product name | PET Plastic Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Manufacturer Introduction Of Flexible PET Plastic Rolls

Desu (pet-sheet.com) as a trusted clear PET plastic sheet supplier, we work with many of the world’s leading manufacturers, so you can choose us with confidence.

Clear PET plastic sheet is one of the most environmentally friendly thermoplastic plastic films. Excellent transparency, thermal stability, low shrinkage, and anti-fog and anti-glare properties make clear PET plastic sheet an excellent choice for a variety of applications in many industries.

Our Certificate

Desu (pet-sheet.com) has won many certifications such as BRC, BSCI, COS, FAMI-QS, FSC, GB, GMP, GSV, HACCP, ISO/TS16949, ISO10012, ISO13485, ISO14001, ISO14004, ISO14010, ISO17025, because of its advanced production technology and management system. ISO17799, ISO22000, ISO9001, ISO9002, OHSAS18001, OHSMS, SA8000, TL9000, CB, CE, FDA, RoHS, Test Report, MSDS.

Our Ordering Process

You can get our products through the following process. If you have related product needs, you can contact us. We look forward to your consultation.

Flexible PET Plastic Rolls Order Process

Step 1: Contact Us

Reach out via email, phone, or our online contact form with your product requirements.

Step 2: Consultation & Inquiry

Our sales team will discuss your specific needs, including product specifications, quantity, and packaging details.

Step 3: Quotation & Confirmation

Based on your inquiry, we will provide a detailed quotation, including pricing, lead time, and shipping options.

Step 4: Order Confirmation

Once you approve the quotation, we’ll confirm the order and proceed with production or shipping.

Step 5: Production & Quality Control

Our team will ensure that your products are manufactured and undergo strict quality control to meet your standards.

Step 6: Shipping & Delivery

We’ll ship the products according to the agreed timeline, with transparent tracking and updates.

PET-SHEET.COM

PET-SHEET.COM