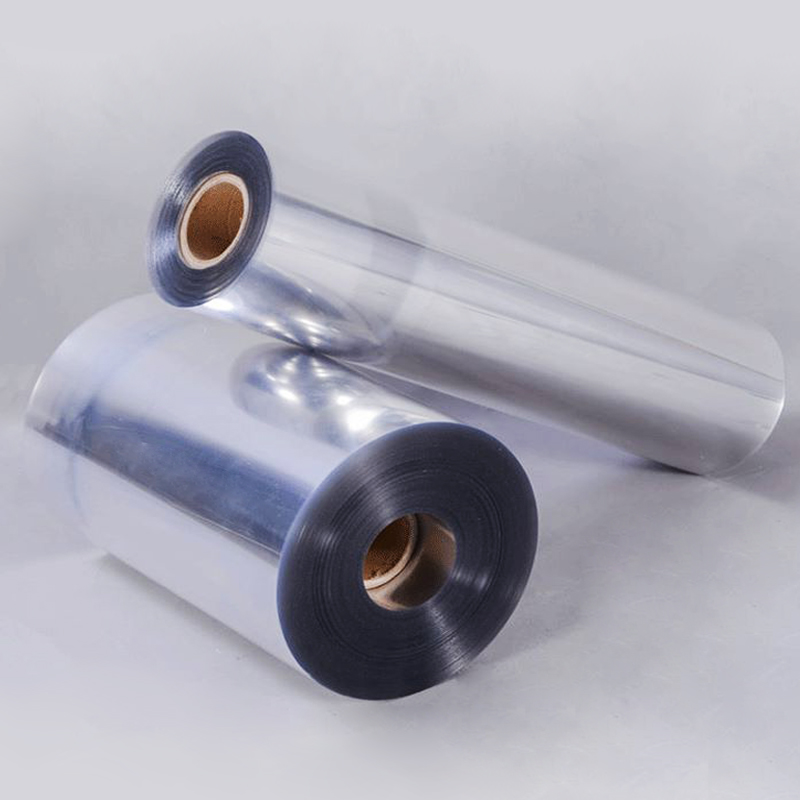

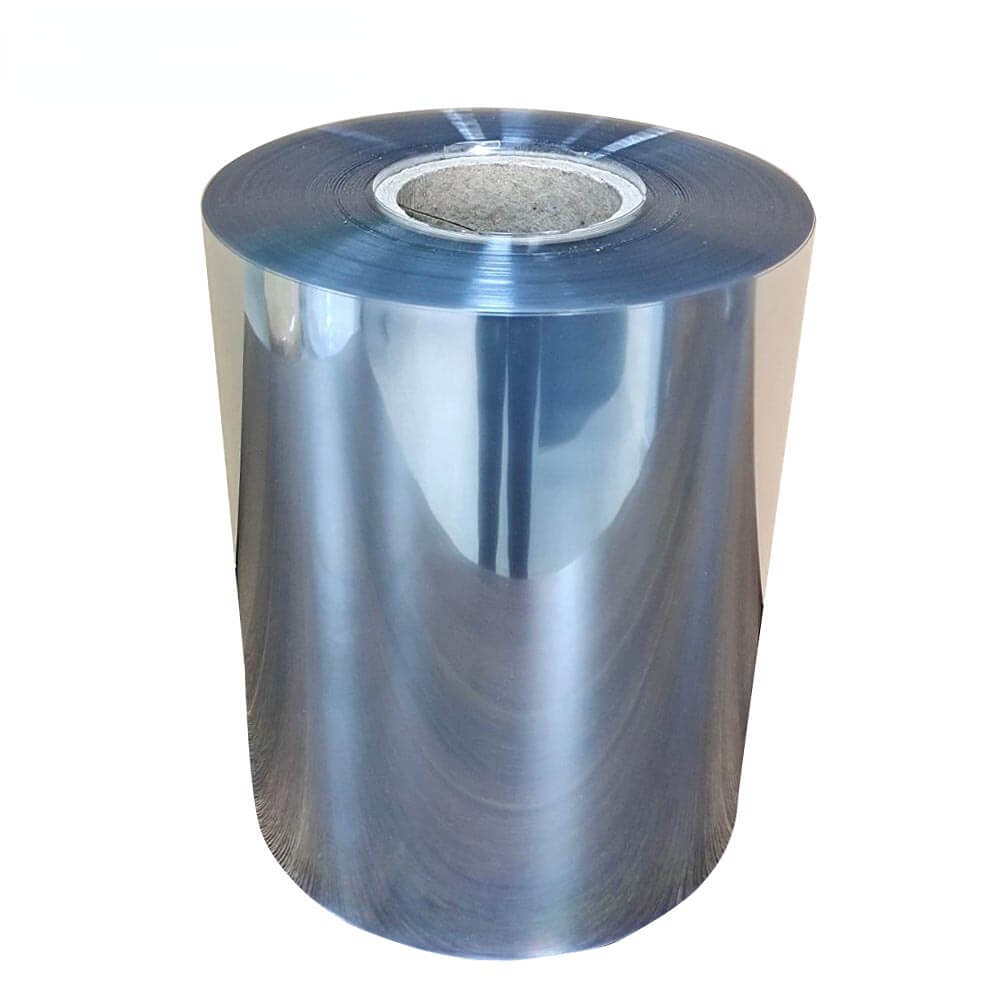

High Quality PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

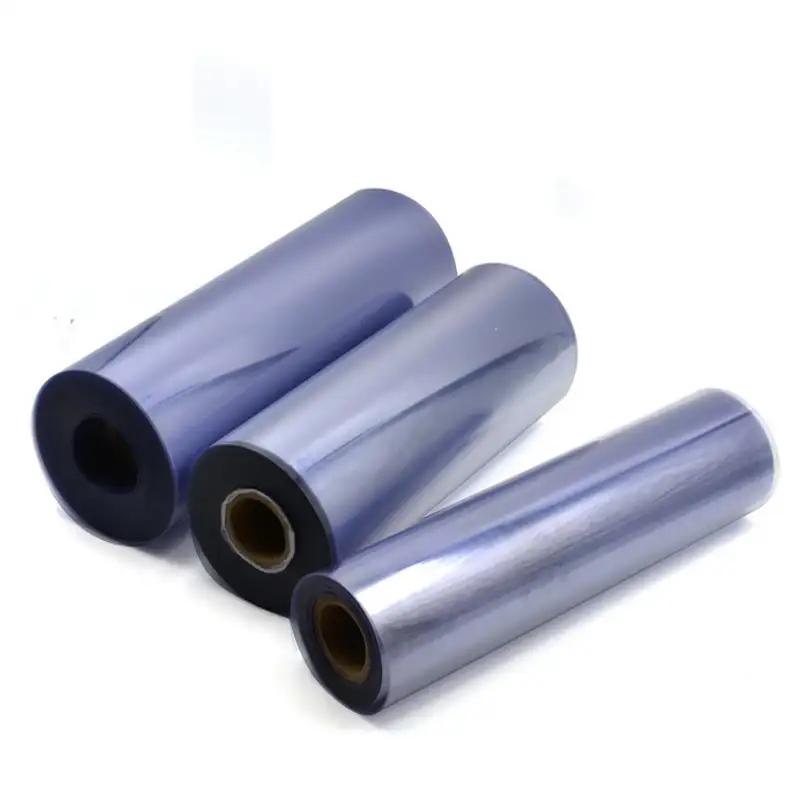

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "High Quality PET Plastic Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

High Quality PET Plastic Rolls – Ideal Choice for Packaging Materials

1. Product Definition

High Quality PET Plastic Rolls are film rolls made from polyethylene terephthalate (PET) through extrusion, stretching and other processes. They have the characteristics of high transparency, high strength, good temperature resistance, environmental protection and recyclability, and are high-end substrates in the packaging industry.

2. Features ( Advantages of Packaging Industry)

| Feature | Description | Packaging Industry Value |

|---|---|---|

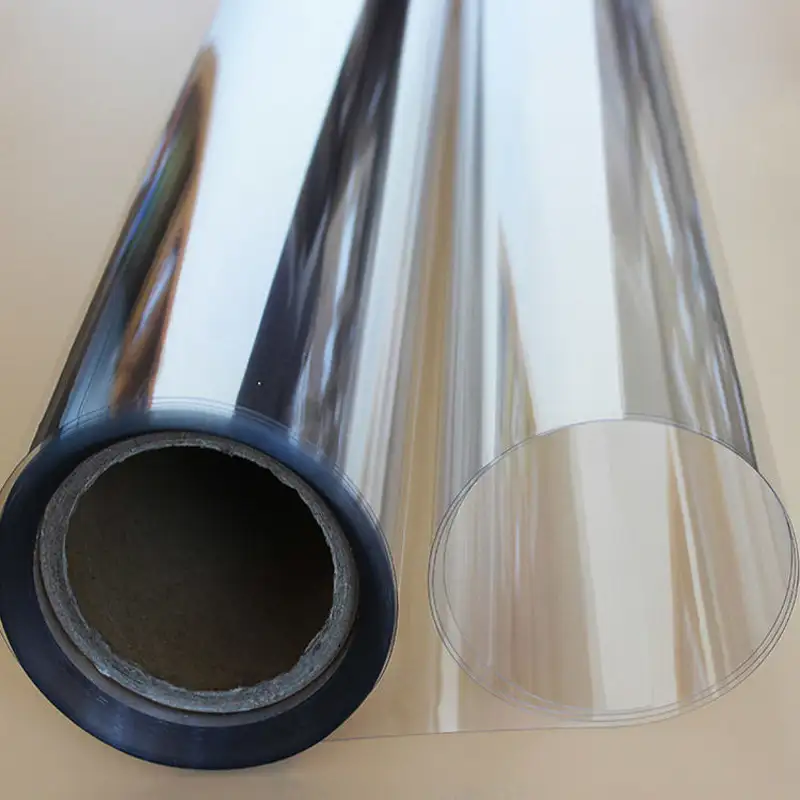

| High Transparency & Gloss | Glass-like clarity for superior product visibility. | Enhances product display, ideal for premium food and cosmetic packaging. |

| High Strength & Tear Resistance | Puncture-resistant and more durable than PE/PP films. | Ensures transport safety and reduces damage rates. |

| Excellent Barrier Properties | Moisture and oxygen barrier (can be enhanced with aluminum coating/lamination). | Extends shelf life of food/pharmaceuticals, replaces aluminum composite films. |

| Temperature Resistance (-70℃~150℃) | Heat-sealable and withstands high-temperature sterilization (e.g., retort packaging). | Suitable for cold chain, microwave heating, and sterile packaging applications. |

| Food-Grade Safety | FDA/EC certified, BPA-free, safe for direct food contact. | Complies with strict food and medical packaging regulations. |

| Eco-Friendly & Recyclable | 100% recyclable, aligns with global plastic reduction trends. | Meets brand sustainability requirements (e.g., carbon-neutral packaging). |

3. Typical packaging application scenarios

(1) Food packaging

Transparent blister boxes (fruit, sushi trays), shrink labels (beverage bottles), aluminized films (snack bags).

(2) Medical packaging

Aluminum-plastic blisters for medicines, sterile protective films for medical devices.

(3) Industrial packaging

Antistatic films for electronic products, surface protective films for hardware products.

(4) Environmentally friendly packaging

Single-material PET composite packaging (recyclable alternative to traditional multi-layer composite materials).

4. Comparison with competing materials (PET vs. PE/PP/PVC)

| Material | Transparency | Strength | Heat Resistance | Barrier Properties | Eco-Friendliness | Cost |

|---|---|---|---|---|---|---|

| PET | ★★★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★★ | Medium-High |

| PE | ★★ | ★★ | ★★ | ★★ | ★★★ | Low |

| PP | ★★★ | ★★★ | ★★★ | ★★ | ★★★ | Low |

| PVC | ★★★★ | ★★★ | ★★ | ★★★ | ★ | Medium |

PET Core Advantage: Achieves the best balance between transparency and strength while meeting environmental requirements.

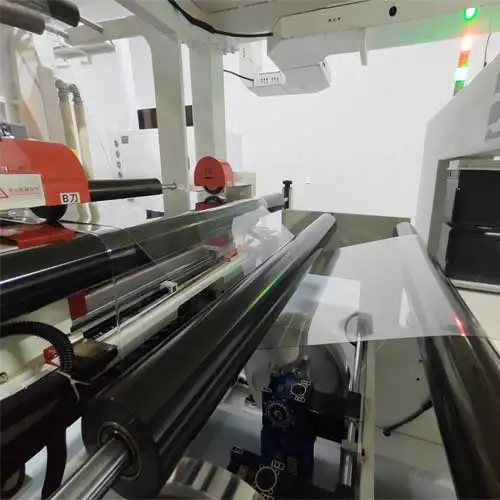

How to produce high quality PET plastic rolls?

Producing high quality PET plastic rolls involves several steps, and attention to detail at each stage is crucial. Here’s an outline of the key factors involved in ensuring high quality:

1. Raw Material Selection

- High Grade PET Resin: The quality of the raw material is fundamental. Ensure that you use high-grade PET resin, preferably from trusted suppliers, to avoid impurities or low molecular weight which can affect the strength and clarity of the final product.

- Additives: Use additives like stabilizers, UV inhibitors, and plasticizers, if needed, depending on the intended use of the PET rolls (e.g., for food packaging or electronics).

2. Polymerization Process

- Polymerization Quality Control: PET resin is produced through polymerization, and this process needs strict quality control to ensure uniform molecular weight distribution. Proper control of temperature and reaction time ensures high-quality PET.

- Viscosity Control: Viscosity plays a huge role in the final quality of PET films. Maintaining the correct viscosity ensures smooth production without defects.

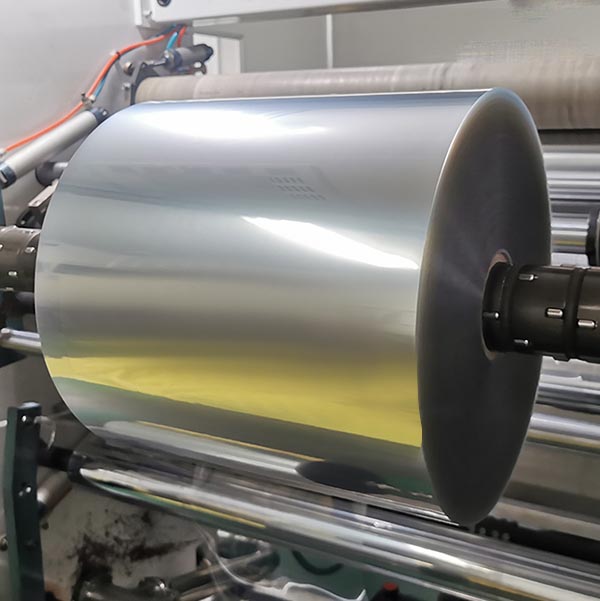

3. Extrusion Process

- Extrusion Temperature: The extrusion temperature should be carefully controlled to avoid degradation of the polymer. Typically, a temperature range of 250°C to 280°C is used for extrusion.

- Extruder Quality: Use high-quality, well-maintained extruders to ensure uniform thickness and quality. Also, ensure that the screws and barrels are suitable for PET processing.

4. Calendering or Casting

- Roller Settings: Calendering machines with precise roller settings are crucial for ensuring uniform thickness and smooth surfaces. Any inconsistency here will lead to defective PET sheets.

- Cooling System: The cooling system after extrusion must be uniform to avoid warping or inconsistent thickness in the PET rolls. Cooling at a steady rate prevents internal stress.

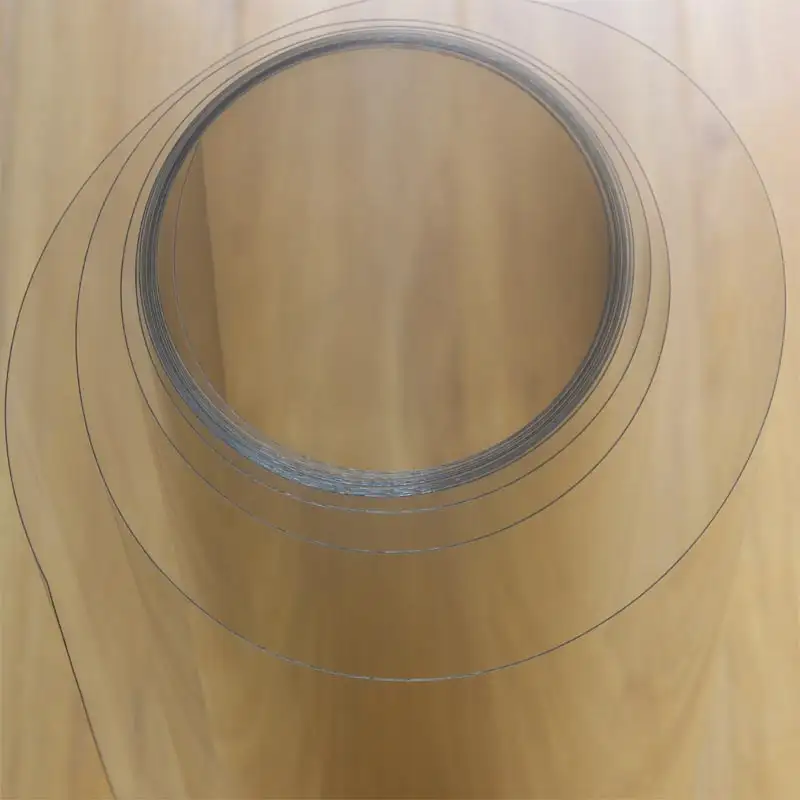

5. Thickness and Clarity Control

- Thickness Control: Regular measurement of the sheet thickness is essential for consistency. This can be done with laser or micrometer gauges.

- Clarity and Optical Quality: PET plastic sheet rolls are often transparent, and clarity is important. Ensure that the extrusion and cooling processes do not introduce bubbles, haziness, or any optical defects.

6. Quality Control and Testing

- Mechanical Properties: Conduct tensile strength, elongation, and impact resistance tests to verify the durability and performance of the PET plastic rolls.

- Surface Defects: Inspect the surface for any scratches, bubbles, or unevenness. These defects can impact the usability of the final product, especially in industries like packaging or electronics.

- Thermal Stability: Ensure the PET plastic rolls maintain stability at higher temperatures, especially if they are intended for food or beverage packaging.

7. Slitting and Winding

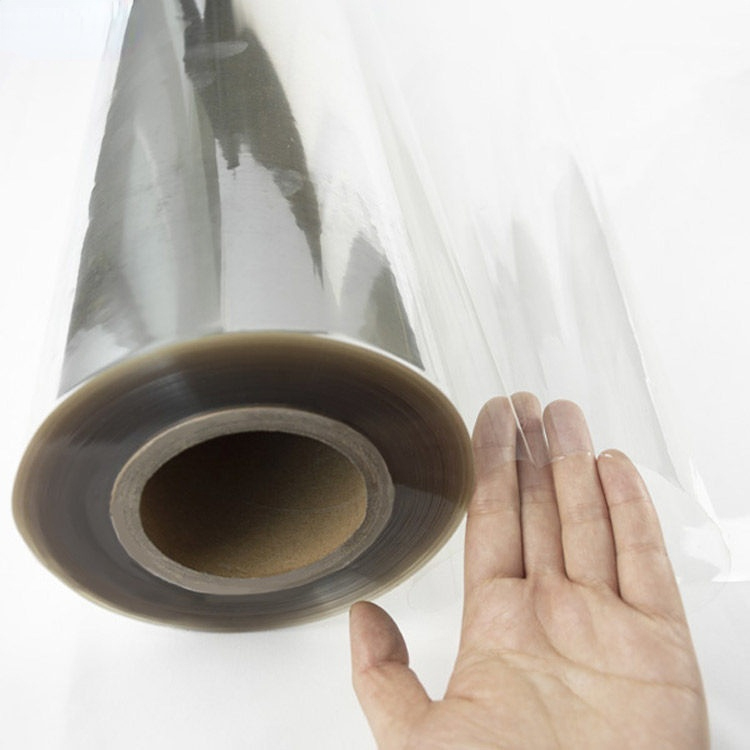

- Precision Slitting: When the large rolls are slit into narrower widths, precision is crucial to prevent jagged edges or uneven tension.

- Winding Tension: The winding tension of the final roll should be adjusted properly to avoid issues like overstretching, tearing, or rolling defects.

8. Packaging and Storage

- Packaging: Pack the PET rolls carefully to avoid damage during transportation. Use protective layers to prevent scratches or pressure marks on the surface.

- Storage Conditions: Store the rolls in a clean, dry area, away from direct sunlight or sources of heat to maintain their quality over time.

9. Customization and Coating (if needed)

- Special Coatings: In some cases, you may need to apply coatings (e.g., anti-fog or anti-static) or further customization to suit specific customer needs.

- Surface Treatment: Treatments like corona discharge can improve the surface adhesion properties, especially for printing or coating purposes.

By managing each step with precision, from raw material selection to final packaging, you can ensure that your PET plastic rolls are of the highest quality, free from defects, and suitable for a wide range of applications.

Product Specifications of High Quality PET Plastic Rolls

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

How to Choose High-Quality PET Plastic Sheets? — A Professional Guide for Packaging Buyers

When selecting high-quality PET plastic sheets, packaging buyers can refer to the following professional guidelines:

1. Material and Performance

Ensure that the PET plastic sheets are made from high-quality raw materials, offering excellent transparency, toughness, heat resistance, and chemical resistance. Make sure it meets specific packaging requirements, such as compliance with food contact material standards for food packaging.

2. Thickness and Size

Choose the appropriate thickness and size based on packaging requirements. The thickness of PET plastic sheets generally determines its strength and transparency. Consider the product’s protection needs when making a selection.

3. Surface Treatment

Understand the surface treatment technologies of the PET sheets, such as embossing and coating, to ensure it is suitable for the required printing and packaging processes, enhancing the packaging’s appearance and functionality.

4. Environmental Friendliness

Choose PET plastic sheets that meet environmental standards, ensuring they are recyclable, non-toxic, and meet industry-specific environmental guidelines.

5. Supplier Reputation and Certification

Select suppliers with a good reputation and relevant certifications to ensure product quality and service. ISO certifications, food-grade certifications, etc., are guarantees of quality.

6. Price and Supply Capability

Consider both price and the supplier’s ability to provide consistent and stable supply. Choose suppliers who offer reasonable pricing and can maintain long-term, stable supply to avoid production disruptions due to shortages or price fluctuations.

If you want to know more about High Quality PET Plastic Rolls, Please contact us for more information.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- UV-resistant PET Sheet Rolls

- 0.5 mm PET plastic rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

- ESD PET Plastic Rolls

- Lightweight PET Plastic Rolls

- 1.2 mm PET plastic rolls

- Factory Price PET plastic rolls

- Wholesale Clear PET plastic rolls

- 1.8 mm Thickness PET Plastic Rolls

- Wholesale Conductive PET Plastic Rolls

- Wholesale PET plastic sheet rolls

- 1.5 mm Pet plastic sheet roll

- Transparent Rigid PET Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM