How do manufacturers choose PET Plastic Rolls?

Considerations for manufacturers to choose PET plastic rolls

Manufacturers can choose PET (polyethylene terephthalate) plastic rolls based on the characteristics and needs of the products in the packaging field he applies.

1. Thickness and specifications

Thicker rolls: for stronger packaging and require higher durability.

Thinner rolls: ideal for lightweight products where cost-effectiveness is more important than high durability.

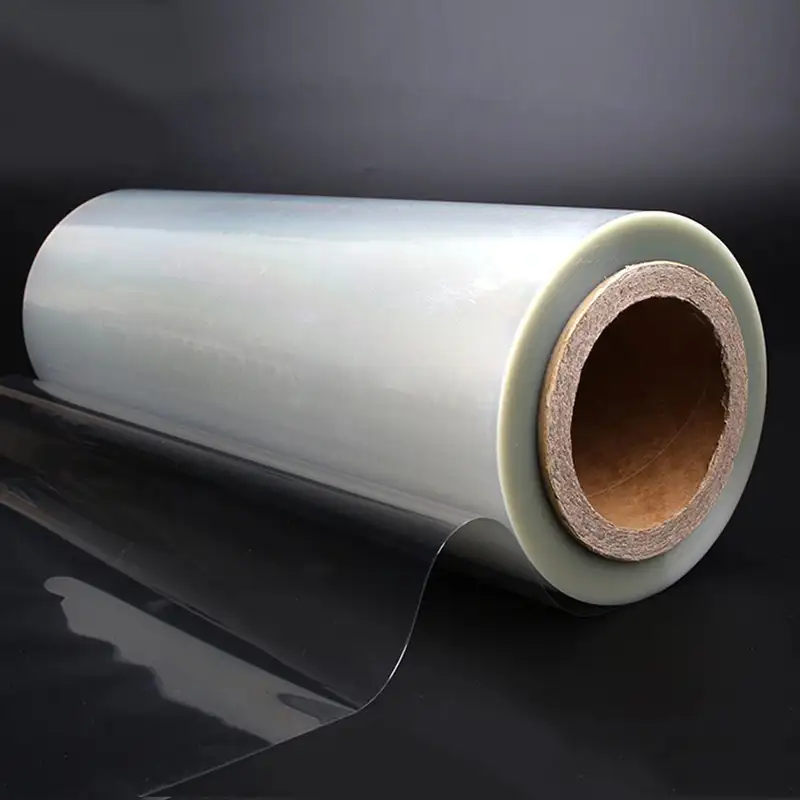

2. Clarity and transparency

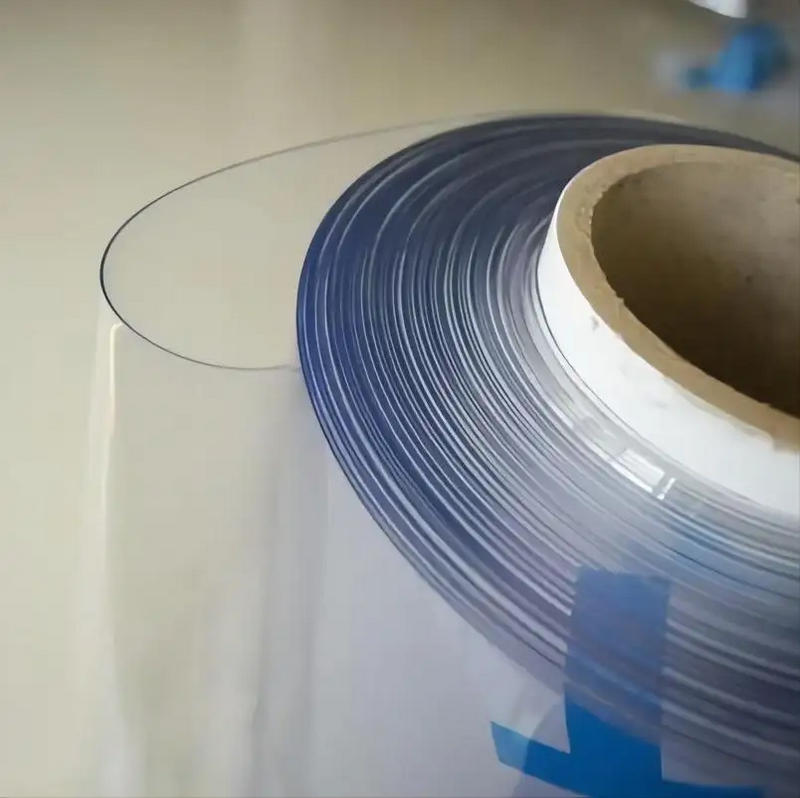

PET plastic is known for its excellent clarity, which makes it ideal for packaging products that need to be visible, such as food, cosmetics, or electronics.

Manufacturers look for the required level of transparency, depending on whether the packaging needs to showcase the product or whether a matte finish is required.

3. Barrier properties

PET plastic rolls has good resistance to moisture, oxygen, and chemicals. For food and beverage packaging, the ability to prevent contamination and extend shelf life is critical.

Manufacturers will evaluate whether they need PET with enhanced barrier properties, such as PET with added coatings or multi-layer structures.

4. Mechanical Strength and Durability

The tensile strength of the material and its resistance to impact are important factors, especially for products that need protection during handling and transportation.

PET is often chosen because of its ability to resist cracking and tearing under normal conditions.

5. Formability and Flexibility

PET can be formed into a variety of shapes and structures, such as shrink film, stretch film, and rigid packaging. The flexibility of PET plastic rolls is important for applications such as shrink wrap or stretch wrap.

6. Cost-Effectiveness

Manufacturers consider the cost of PET plastic rolls relative to other packaging materials such as PVC or PE (polyethylene). PET is generally more expensive, but its properties may justify it in a specific application.

Long-term durability and cost-effectiveness over the product life cycle are also key factors.

7. Sustainability Considerations

Many manufacturers choose recycled PET (rPET) to reduce their environmental impact. PET is recyclable, and some manufacturers choose it because of its recyclability or because it is made from recycled materials.

Companies that prioritize sustainability may prefer suppliers that offer rPET or PET film that can be easily recycled or has minimal environmental impact.

8. Compliance with Industry Standards

Depending on the industry, manufacturers may need to ensure that their PET rolls meet regulatory standards for food safety, pharmaceuticals, or other specific requirements.

Certifications such as FDA approval for food packaging or ISO certification for quality control are often considered.

9. Compatibility with Equipment

PET plastic rolls must be compatible with the manufacturer’s packaging equipment. Some PET films may be better suited for high-speed automated processes, while others may be better suited for manual packaging or small batch production.

10. Supplier Reliability

Consistency and reliability of supply are critical. Manufacturers generally prefer suppliers who can deliver PET rolls on time, in the required quantities, and with minimal defects.

11. Environmental and Health Considerations

Health and safety considerations, especially in the case of food and pharmaceuticals, also play a role. PET is often chosen as a food packaging material because it is inert and non-toxic, ensuring that it will not leach harmful chemicals into the product.

By evaluating these factors, manufacturers can choose the type of PET plastic roll that best suits their specific needs, including performance, cost, and end-use applications.

What is PET Plastic Rolls?

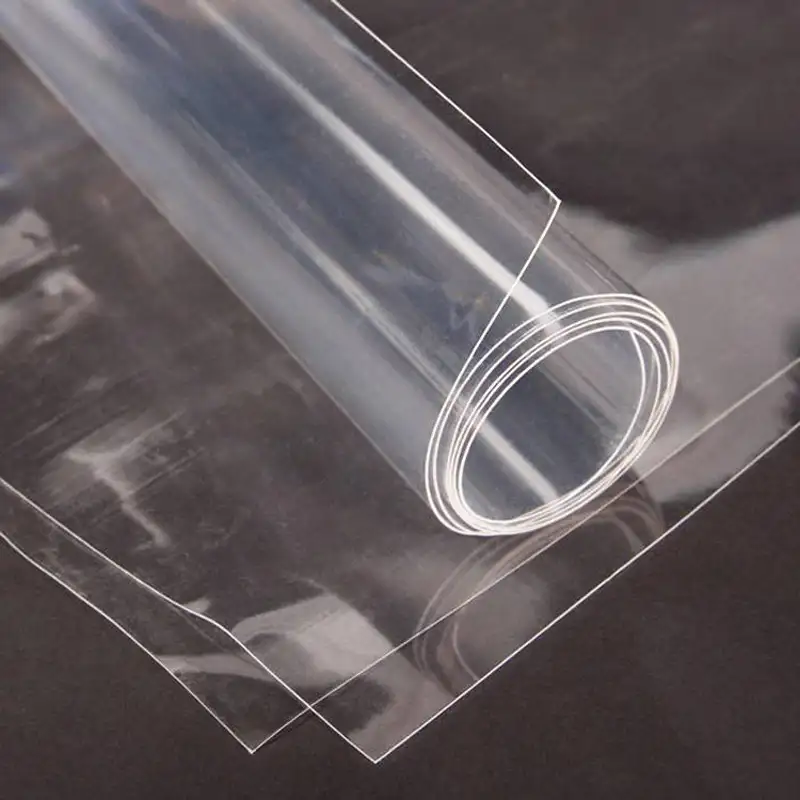

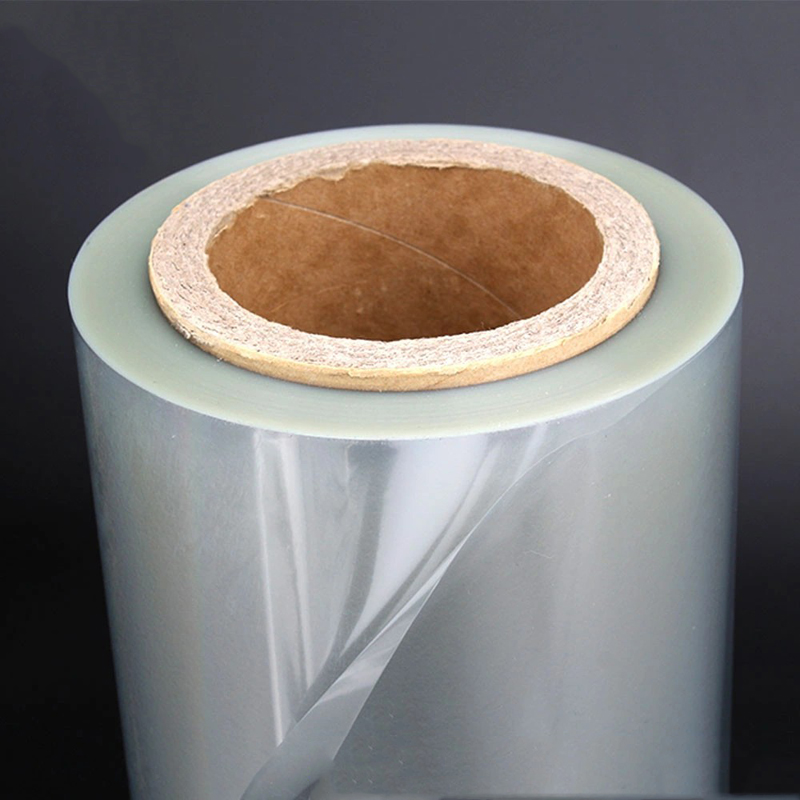

PET plastic rolls refer to sheets or rolls of plastic material made from Polyethylene Terephthalate (PET), a type of thermoplastic polymer.

PET is widely used due to its strength, durability, and recyclability. These rolls are typically used in packaging, especially for food and beverages, as well as in manufacturing various products.

PET plastic rolls can be clear or colored, and they come in various thicknesses, depending on the intended use. They are commonly used for:

(1) Food packaging: PET is often used to create shrink films, trays, and wraps to protect food and extend shelf life.

(2) Industrial applications: PET rolls can also be used for applications like insulation or in the production of various containers and products.

The material is well-regarded for being lightweight, strong, and resistant to chemicals and moisture. It is also recyclable, making it a popular choice for sustainable packaging solutions.

Why Choose Our PET Plastic Rolls?

There are several significant advantages to choosing PET plastic rolls from Pet-sheet.com, especially in the field of thermoforming and blister packaging. Here are some key advantages:

1. High-quality materials

PET (polyethylene terephthalate) is a highly transparent, heat-resistant and chemically resistant plastic suitable for a variety of packaging needs. Our PET plastic rolls are produced using high-quality raw materials to ensure their physical properties and service life.

2. Stable quality control

As a factory-certified company, Pet-sheet.com is committed to strict quality control in every production link to ensure that the products meet international standards. We provide high-quality PET plastic rolls through advanced production equipment and technology to meet the packaging needs of different customers.

3. Customized service

According to customer needs, Pet-sheet.com provides customized solutions. Whether it is size, thickness, surface treatment or color, you can customize PET plastic rolls according to product characteristics to ensure that your packaging requirements are met to the greatest extent.

4. Wide range of applications

Our PET plastic rolls are widely used in blister packaging in many industries such as food, electronics, medicine, cosmetics, etc. It has good transparency, strong structure and excellent protective properties, which can effectively protect the contents of the package.

5. Environmentally friendly and recyclable

PET is an environmentally friendly material that can be 100% recycled and reused, meeting global environmental protection requirements. Using our PET plastic rolls can not only ensure the safety of packaging products, but also contribute to the sustainable development of the company.

6. Production base and supply chain advantages

We have multiple production plants and offices in Shanghai and Hong Kong, with strong production capacity and supply chain management capabilities to ensure the punctuality of delivery and high stability of products. In addition, our global logistics network also provides customers with fast transportation and distribution services.

7. Customer-oriented service concept

Pet-sheet.com always puts customer needs first. We welcome customers to visit the factory, understand the production process, and provide one-to-one technical support and after-sales service to ensure that customers get the best experience throughout the purchase and use process.

8. Competitive price

Through the optimization of production processes and supply chain management, PET-sheet is able to provide high-quality PET plastic rolls at competitive prices. We not only focus on product quality, but also strive to help customers reduce packaging costs through effective cost control.

In general, choosing PET plastic rolls from Pet-sheet.com means choosing a company with rich experience, strong technical support, environmental protection concepts and innovative spirit as a long-term partner, which can provide all-round support for your packaging needs.

More Product Recommendations

In addition to providing you with ordinary PET plastic rolls, we can also provide you with PET plastic rolls of other properties and sizes. We look forward to your consultation.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM