How to avoid yellowing of PET plastic rolls?

Avoid yellowing of PET plastic rolls

To avoid yellowing of PET plastic rolls, which can occur due to oxidation, UV exposure, or thermal degradation, follow these preventive measures:

1. Use High Quality Raw Materials

Ensure the PET resin used is of high purity and free from impurities that can accelerate degradation and yellowing.

2. Add UV Stabilizers and Antioxidants

Incorporate UV stabilizers and antioxidants during the manufacturing process to protect the PET from UV radiation and oxidative degradation, which are common causes of yellowing.

3. Control Processing Conditions

- Temperature Control: Avoid excessive heat during extrusion or thermoforming, as high temperatures can degrade PET and cause yellowing.

- Residence Time: Minimize the time PET plastic rolls is exposed to high temperatures during processing to reduce thermal degradation.

4. Proper Storage

- Avoid Direct Sunlight: Store PET plastic rolls in a cool, dark place to prevent UV-induced yellowing.

- Control Humidity: Keep the storage environment dry to avoid moisture-related degradation.

- Temperature: Store at moderate temperatures (ideally below 30°C or 86°F) to prevent thermal aging.

5. Use Protective Coatings

Apply UV-resistant coatings or laminates to the PET surface to shield it from sunlight and environmental factors.

6. Avoid Chemical Exposure

Keep PET rolls away from chemicals, such as solvents or cleaning agents, that can react with the material and cause discoloration.

7. Regular Maintenance of Equipment

Ensure processing equipment is clean and free from residues that could contaminate the PET and lead to yellowing.

By following these steps, you can significantly reduce the risk of yellowing and maintain the clarity and quality of PET plastic rolls over time.

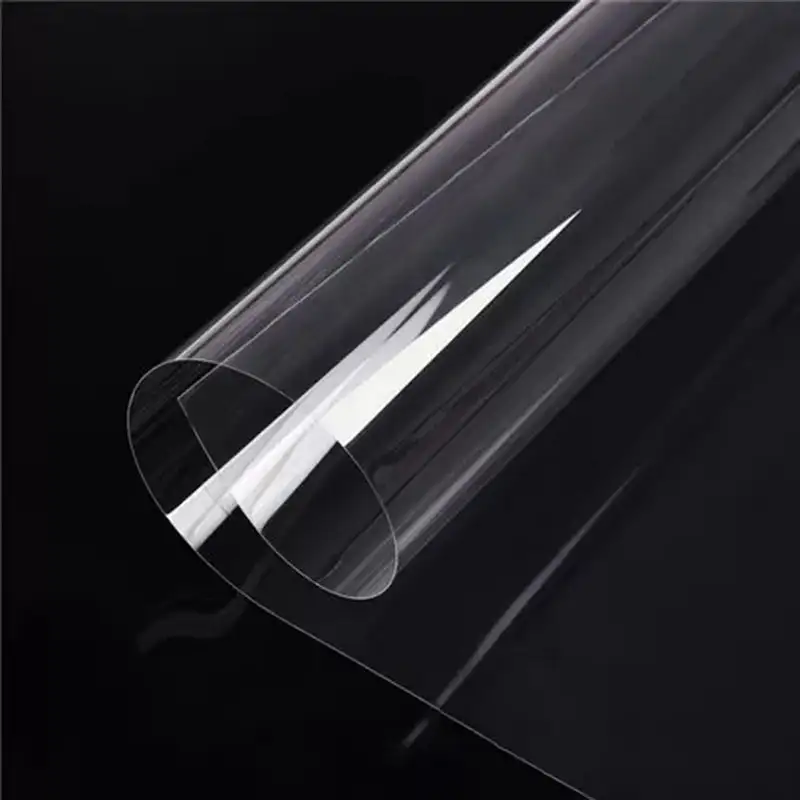

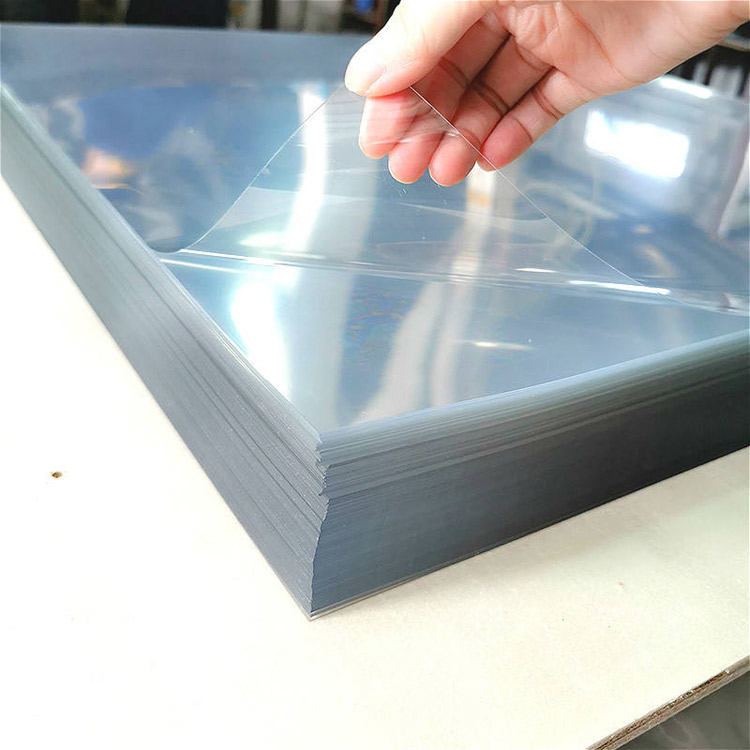

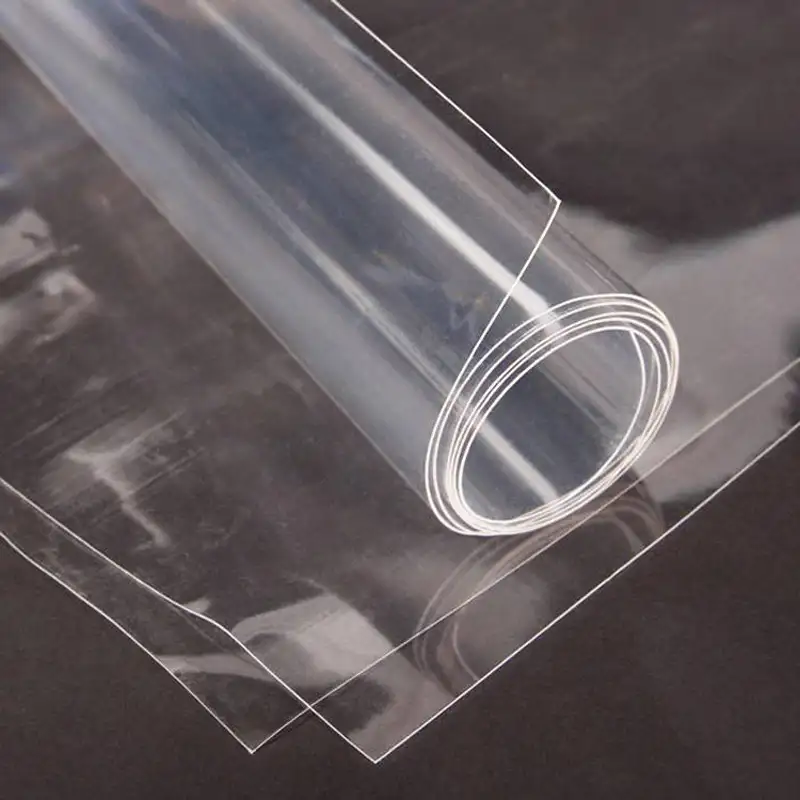

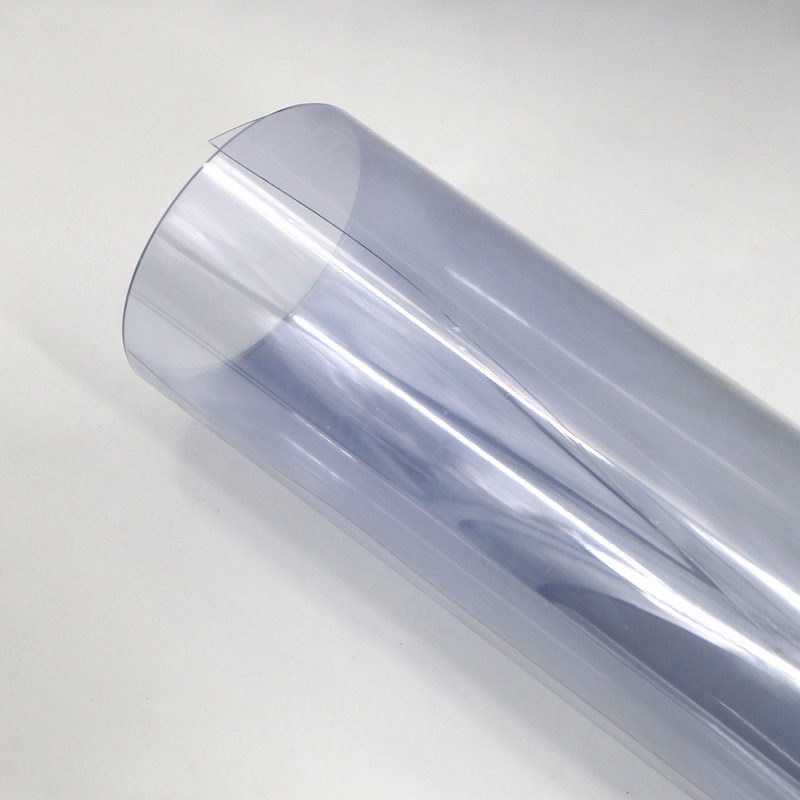

Product Introduction of PET plastic rolls

Polyethylene Terephthalate (PET) plastic rolls are a top choice across various industries due to their durability, clarity, and recyclability. Offering excellent strength, transparency, and moisture resistance, PET is ideal for packaging, thermoforming, and more. Lightweight and cost-effective, PET rolls help reduce shipping expenses while maintaining product integrity.

They are also 100% recyclable, making them an environmentally friendly option. With excellent barrier properties and versatility, PET is widely used in packaging for food, pharmaceuticals, and electronics. As sustainability becomes a key focus, PET rolls remain a reliable and eco-conscious material solution.

PET plastic rolls

- Brand:DESU

- Origin: Shanghai, China

- Width: 300-1400mm

- Barrier material: PET plastic sheet roll

- Processing methods: Lamination / Multilayer co-extrusion

- Thickness: 0.2- 2.0 mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

- Color: Transparent/Custom color

- MOQ: 5tons

These rolls are manufactured through a process of extrusion where PET resin is melted and formed into thin sheets, which are then rolled into convenient-sized rolls for packaging applications. PET plastic rolls are available in various thicknesses, widths, and lengths, catering to diverse packaging needs across different industries.

More Product recommendations

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM