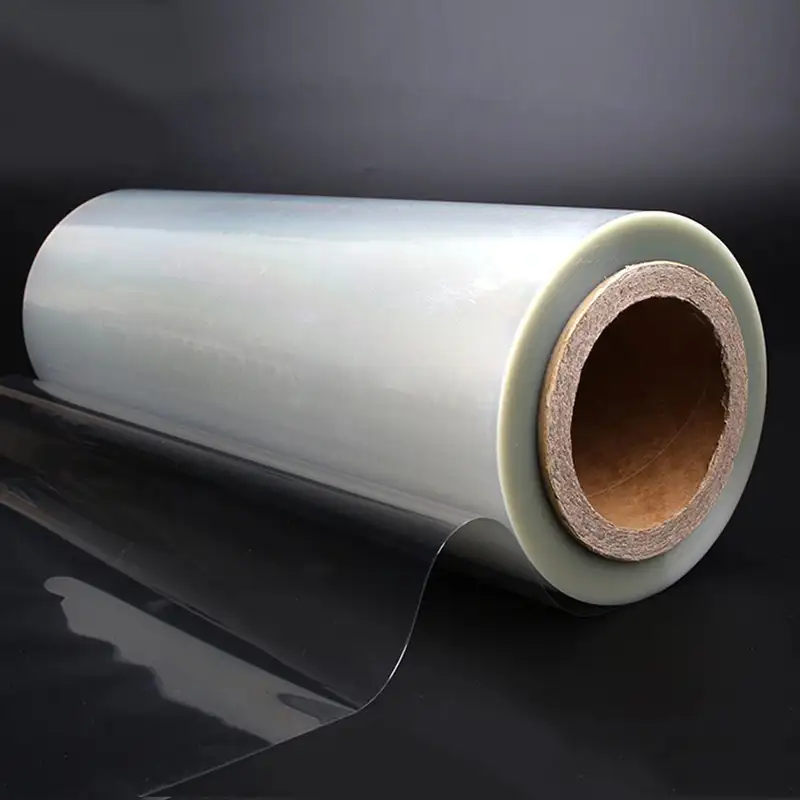

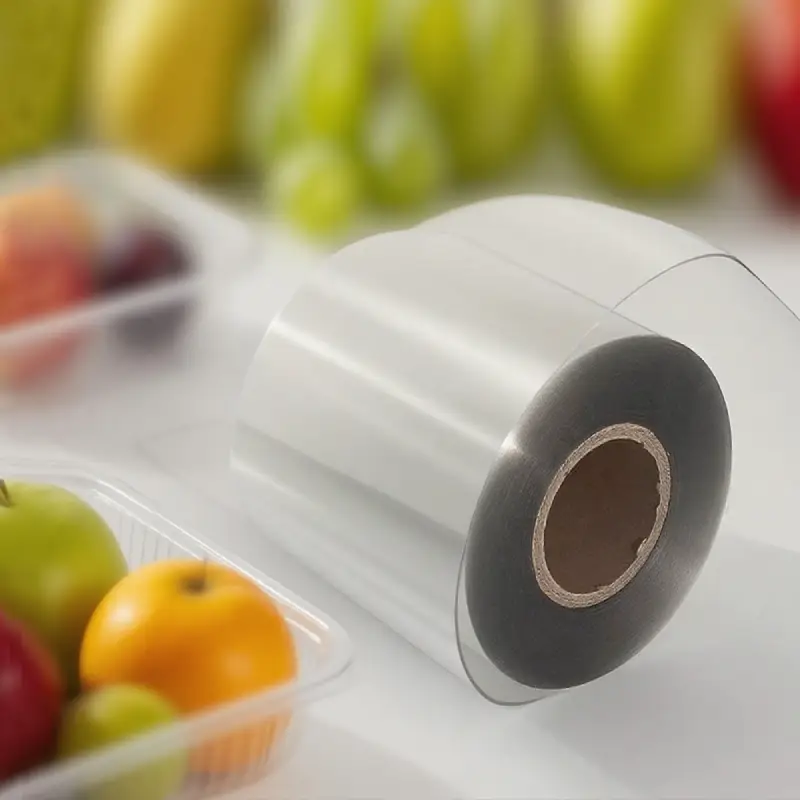

Laminated PET Sheet Roll

PET-SHEET.COM

PET-SHEET.COM

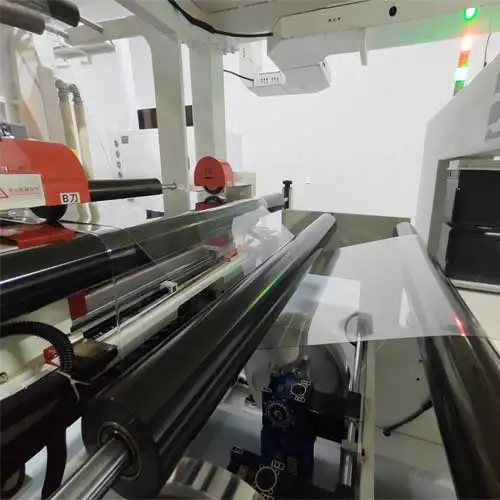

- Production Limits:

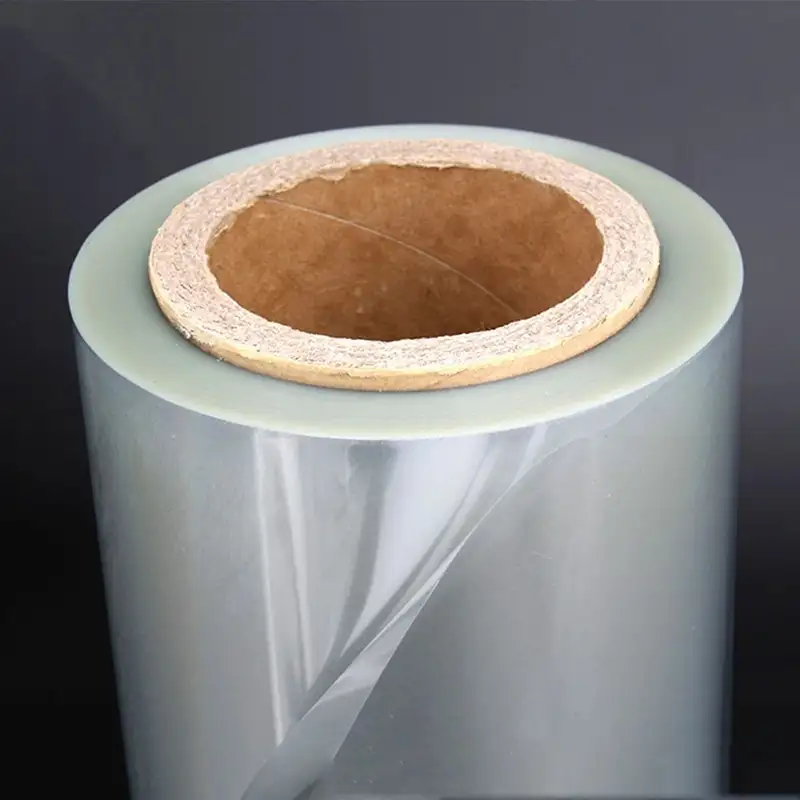

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

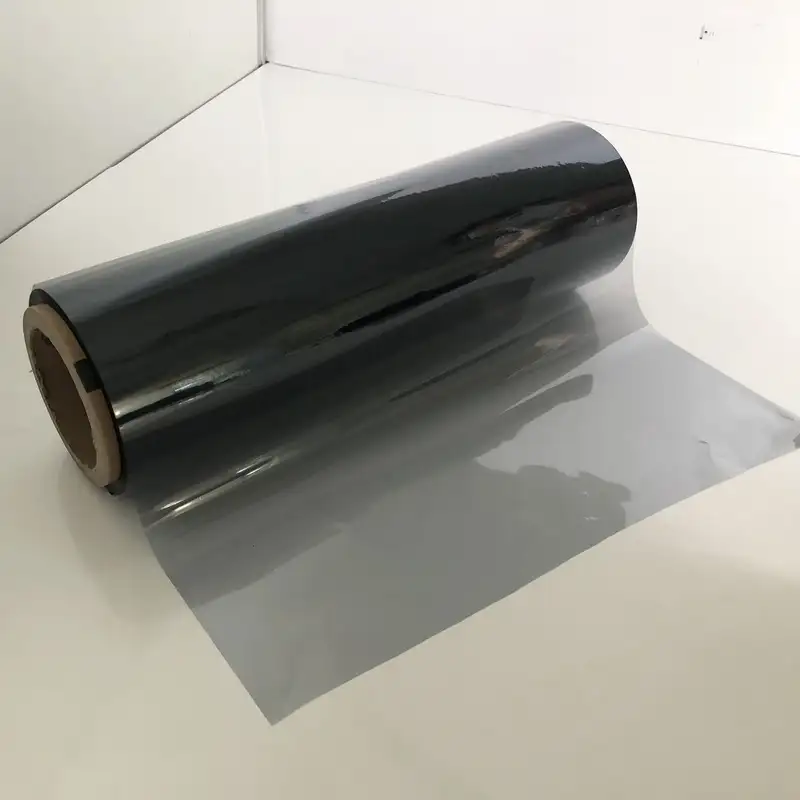

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? APET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid APET Sheet Roll for thermoforming or blister packaging. As to "Laminated PET Sheet Roll", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Our Laminated PET Sheet Roll offers a versatile solution for various packaging and industrial applications. This roll combines the strength and durability of PET (Polyethylene Terephthalate) with the added benefits of lamination, providing enhanced protection, stability, and versatility for your packaging needs.

Features:

- PET Base Material: Crafted from high-quality PET material, ensuring superior strength, durability, and dimensional stability for diverse applications.

- Lamination: Enhanced with lamination for additional protection, barrier properties, and customization options, catering to specific packaging requirements.

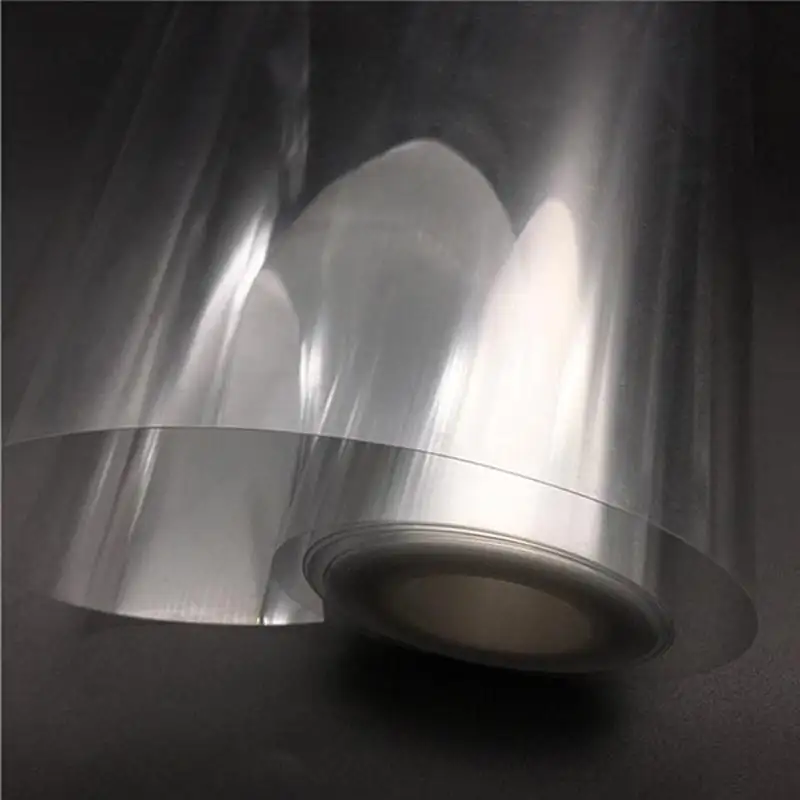

- Excellent Clarity: Maintains excellent clarity and transparency, allowing for optimal visibility of packaged products, labels, and branding elements.

- Enhanced Strength: Offers enhanced strength and tear resistance, reducing the risk of damage or breakage during handling, transportation, and storage.

- Customizable Options: Available in various configurations, including different lamination types (e.g., matte, glossy), thicknesses, and widths, to suit specific application needs.

- Chemical Resistance: Provides resistance to chemicals, oils, and moisture, ensuring stability and integrity in various environmental conditions.

- Heat Sealability: Compatible with heat sealing processes, enabling secure sealing of packages to maintain product freshness, integrity, and tamper resistance.

Data Sheet:

PET-SHEET.COM

PET-SHEET.COM