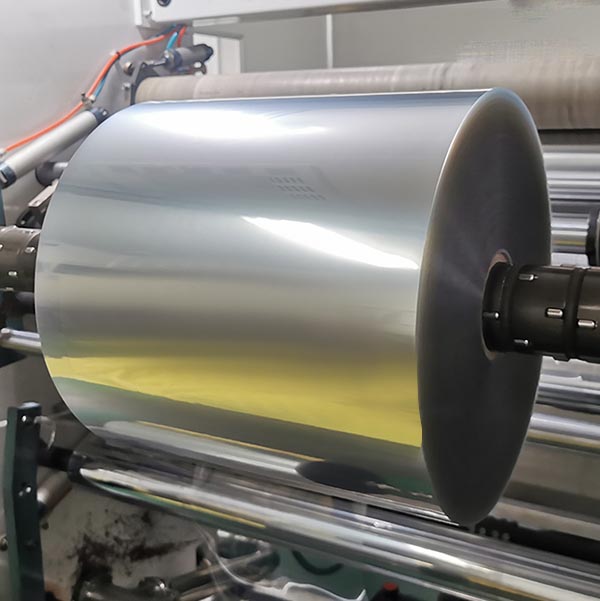

Lightweight PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

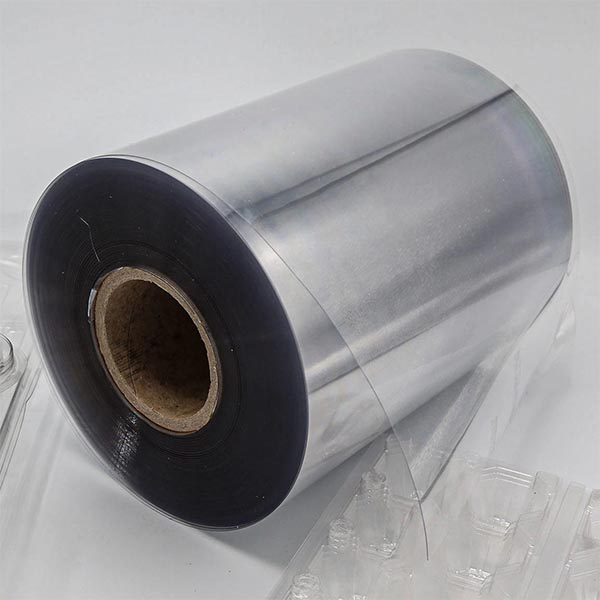

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "Lightweight PET Plastic Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of Lightweight PET Plastic Rolls

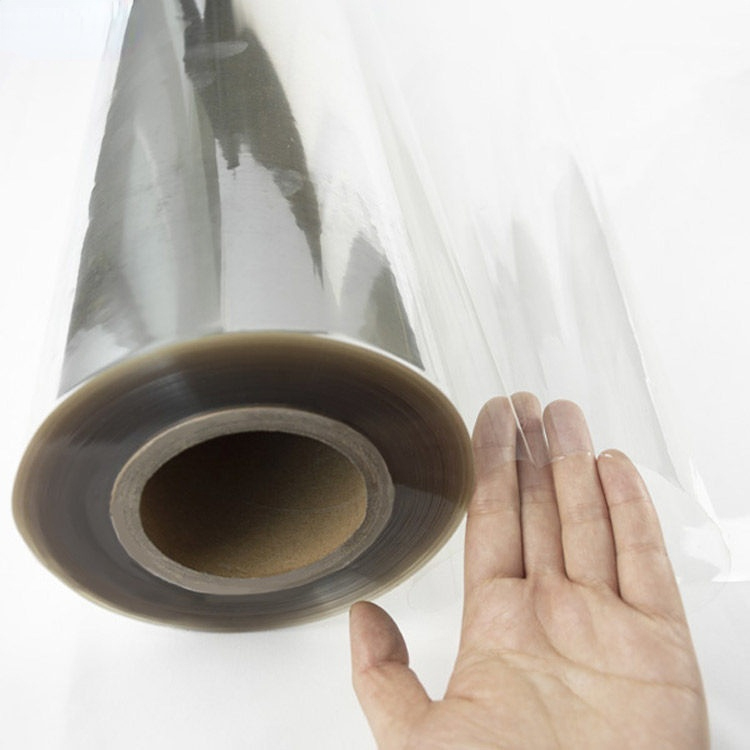

Lightweight PET plastic rolls are flexible sheets made from polyethylene terephthalate (PET) resin, a thermoplastic polymer known for its transparency, strength, and recyclability. These rolls are commonly used for packaging purposes across a wide range of industries due to their light weight, durability, and versatility.

PET plastic rolls are often favored for their ability to provide barrier protection against moisture, gas, and odor, making them suitable for storing and shipping a wide range of products, including food, beverages, pharmaceuticals, and consumer goods. Additionally, PET plastic rolls are environmentally friendly as they are fully recyclable, contributing to sustainable packaging solutions.

Key Features of Lightweight PET Plastic Rolls

Lightweight PET plastic rolls the quality and specification of the material are important to ensure it meets your requirements for strength, clarity, and performance.

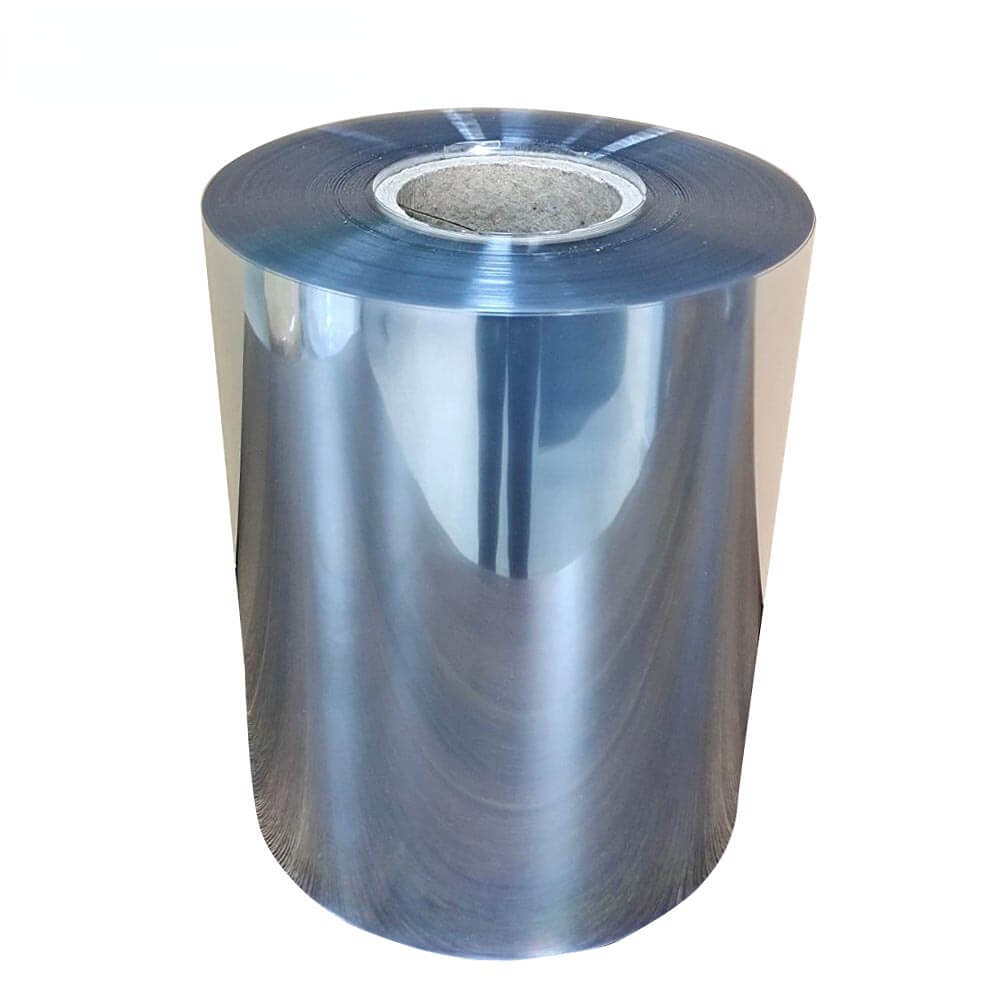

1. High Strength-to-Weight Ratio: Lightweight PET plastic rolls are known for being both lightweight and durable, making it ideal for reducing shipping costs while maintaining strength and functionality.

2. Clarity and Transparency: Lightweight PET plastic roll is highly transparent, providing excellent visibility of packaged goods, which is especially important in retail packaging.

3. Good Chemical Resistance: Lightweight PET plastic rolls has good resistance to a variety of chemicals, making it suitable for food and beverage packaging.

Recyclability: PET is one of the most recyclable plastics, contributing to sustainability efforts in the packaging industry.

4. Thermoformability: Lightweight PET plastic rolls can be easily thermoformed into different shapes, making them versatile for packaging applications.

5. Customization Options: These rolls can be tailored in terms of thickness, color, and finish to meet specific customer needs.

Application of Lightweight PET plastic rolls

Lightweight PET plastic rolls are used in a variety of applications across multiple industries, thanks to their flexibility, strength, and transparency. Here are some key applications:

1. Food Packaging: Lightweight PET plastic rolls are widely used for packaging food items like snacks, fresh produce, and ready-to-eat meals. Their transparency allows consumers to see the product inside, while also protecting food from contaminants and extending shelf life.

2. Cosmetics and Pharmaceuticals: These rolls are commonly used for blister packaging of cosmetic items like creams, lotions, and pills. PET provides a clear, protective barrier while enhancing product visibility on shelves.

3. Consumer Electronics: Lightweight PET plastic rolls are used for packaging electronics and accessories such as batteries, chargers, and small gadgets. The material’s durability helps protect delicate products during shipping and handling.

4. Toys and Retail Products: Lightweight PET plastic rolls are used in retail packaging, such as blister packs, for toys and other consumer goods. Their clarity and strength make them an ideal choice for displaying products attractively while keeping them safe.

5. Medical Devices and Equipment: PET plastic rolls are used for packaging medical devices, surgical tools, and diagnostic equipment. The material’s sterilizability and protective properties are essential in this sector.

6. Industrial Packaging: In the industrial sector, Lightweight PET plastic rolls are used for packaging parts, components, and tools. The strength of the material ensures that items are securely protected during transportation.

7. Consumer Goods: Lightweight PET plastic rolls are also used in packaging household products like detergents, cleaning supplies, and pet food due to its excellent barrier properties and ease of customization.

Product Parameter of Lightweight PET plastic rolls

| Product name | Lightweight PET Plastic Roll, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside + pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Why Choose pet-sheet.com

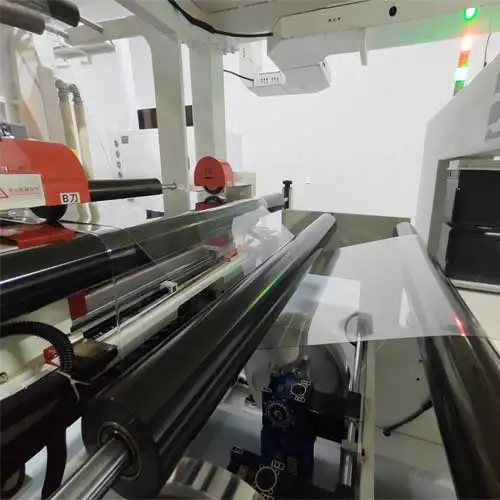

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

- 0.7mm PET Plastic Rolls

- Pet plastic rolls for prepared food packaging

- 1mm Conductive Transparent PET Plastic Sheet Rolls

- PET plastic rolls for Electronic component packaging

- Thermoforming PET Plastic Sheets for Toy Packaging

- FAD Clear PET Sheet Rolls

- High Quality PET Plastic Rolls

- Flexible PET Plastic Rolls

- Blister Packaging PET Rolls

- Thermoforming PET Sheets

- PET thermoformed blister sheet rolls

- UV-resistant PET Sheet Rolls

- 0.5 mm PET plastic rolls

- 1.8 mm PET plastic rolls

- o.4 mm PET plastic sheet rolls

PET-SHEET.COM

PET-SHEET.COM