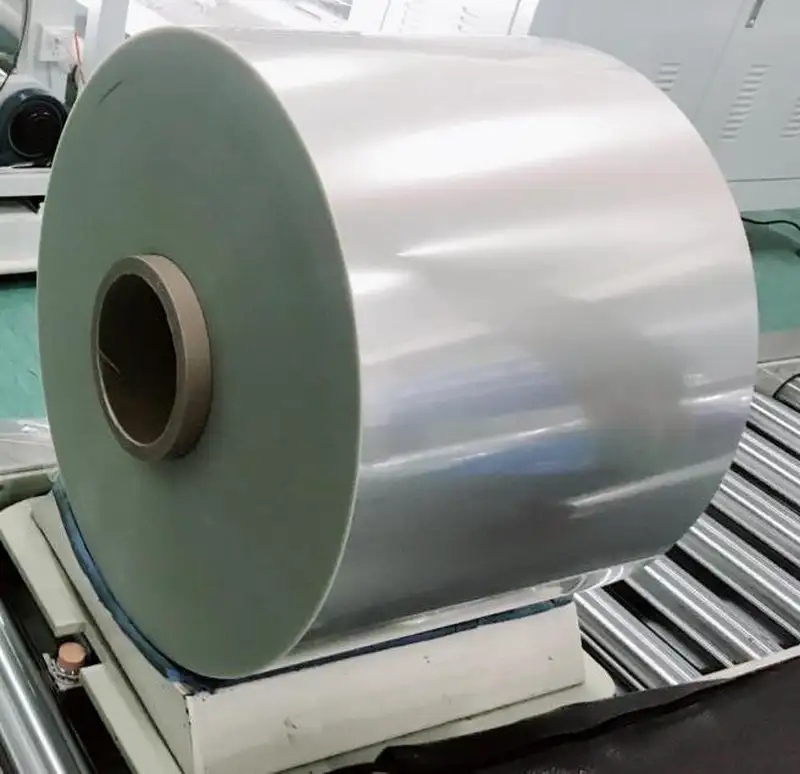

PET plastic rolls for drink cups

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

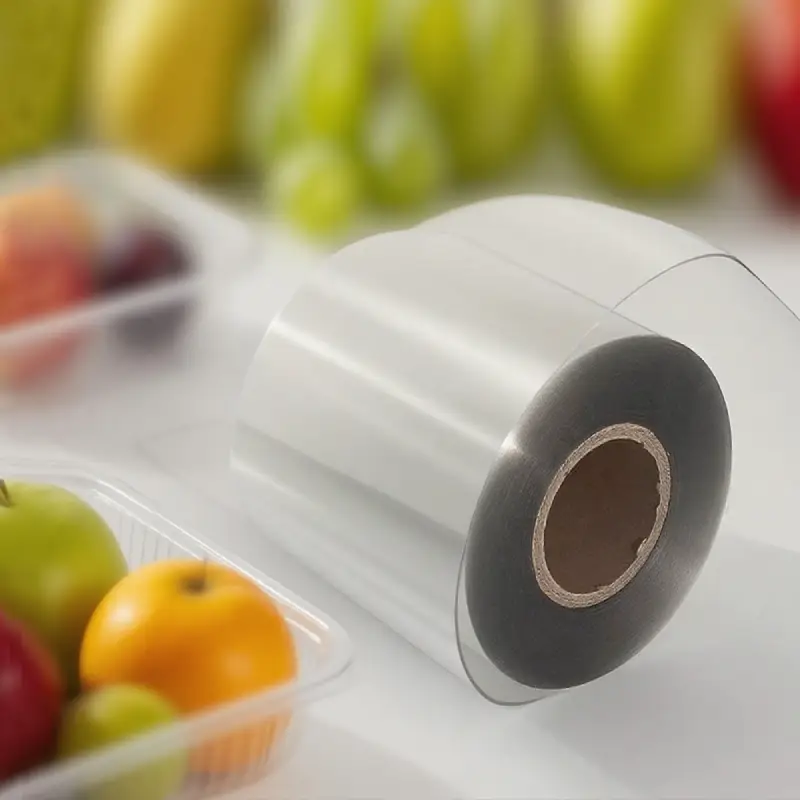

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? . pet-sheet.com is A factory focus on Manufacturer and Export rigid for thermoforming or blister packaging. As to "PET plastic rolls for drink cups", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction Of PET plastic rolls for drink cups

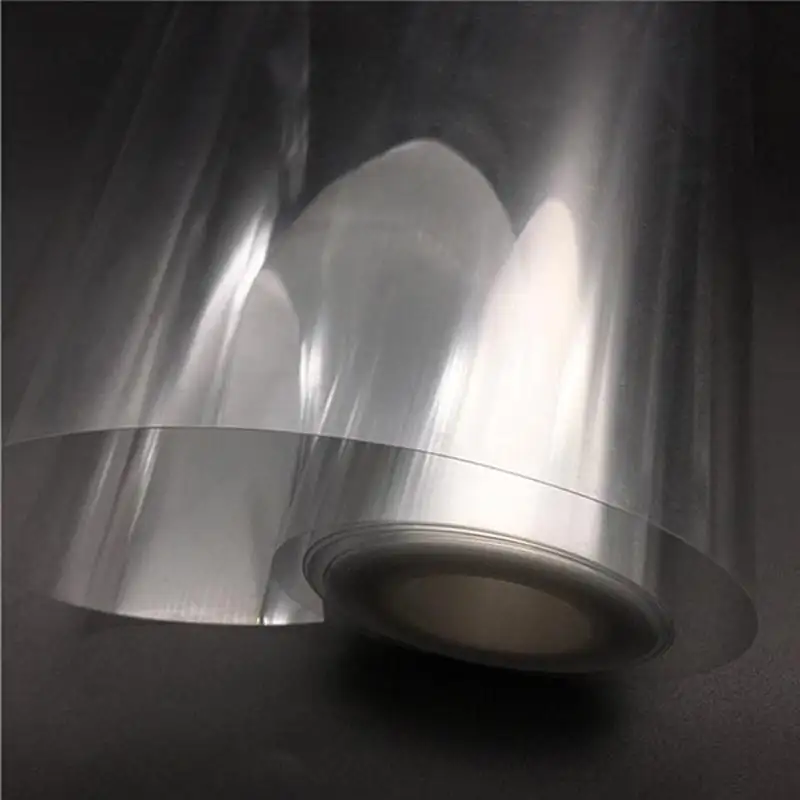

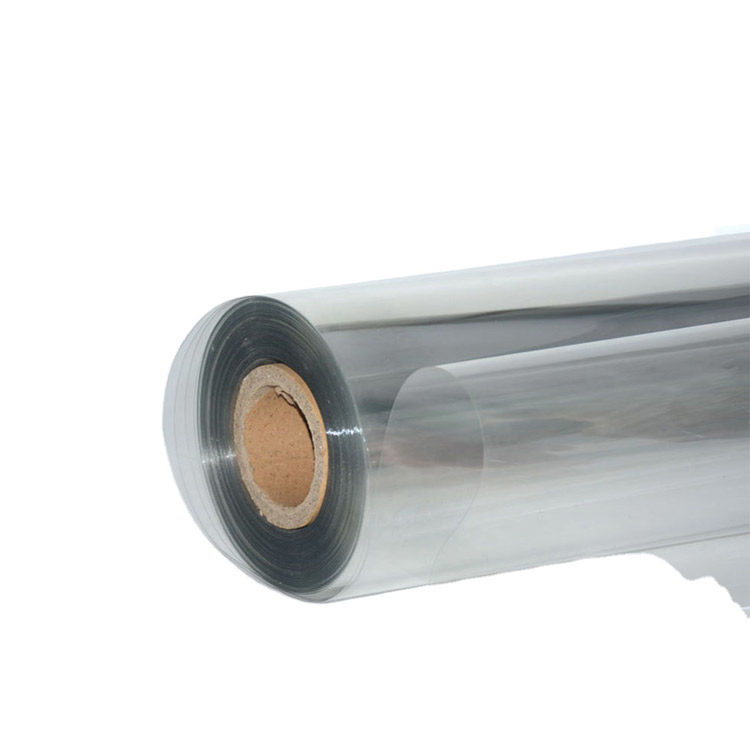

PET (Polyethylene Terephthalate) plastic rolls are a versatile material widely used in the beverage industry for manufacturing drink cups. PET is a thermoplastic polymer known for its excellent clarity, strength, and durability, making it an ideal choice for various packaging applications, especially for drink cups. These plastic rolls can be easily thermoformed into various shapes and sizes to meet different market needs.

Key Features of PET Plastic Rolls for Drink Cups

1. High Transparency: PET plastic rolls offer crystal-clear transparency, which is highly valued in drink cups as it allows consumers to see the contents inside, enhancing the overall presentation of beverages such as iced coffee, juices, soft drinks, and more.

2. Strength and Durability: PET plastic roll is known for its toughness and resistance to cracking, ensuring that drink cups made from this material can withstand daily handling, transportation, and use without breaking or deforming.

3. Lightweight: PET drink cups are lightweight, making them easy to transport and carry, while still maintaining durability. This also helps reduce shipping costs, an important factor in large-scale beverage packaging.

4. Recyclability: PET is 100% recyclable, making it a sustainable option for drink cups. Post-consumer PET products can be collected and reprocessed into new PET items, contributing to a circular economy and reducing plastic waste.

5. Barrier Properties: PET plastic rolls has excellent barrier properties against gases like oxygen and carbon dioxide, which helps preserve the freshness of beverages, particularly carbonated drinks, by maintaining their carbonation and flavor over time.

6. Thermoformability: PET plastic rolls are easily thermoformed into different cup shapes and sizes, offering flexibility for creating a variety of beverage cup designs, including those with customized branding or special features like embossed logos or textured surfaces.

Applications of PET Plastic Rolls for Drink Cups

1. Cold Beverages: PET cups are commonly used for cold drinks such as iced coffee, smoothies, milkshakes, soft drinks, and juices, offering clarity and strength while keeping the beverage fresh.

2. Single-Use and Takeaway Cups: PET plastic rolls are often used in single-use drink cups for takeaway services, widely seen in cafes, fast food restaurants, and convenience stores.

3. Lids and Accessories: PET plastic rolls are also used to create lids that fit securely onto drink cups, helping prevent spills and offering a convenient solution for consumers on the go.

PET plastic rolls parameters

| Product name | PET plastic roll for drink cups, Food grade PET sheet, |

| Product Category | APET, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

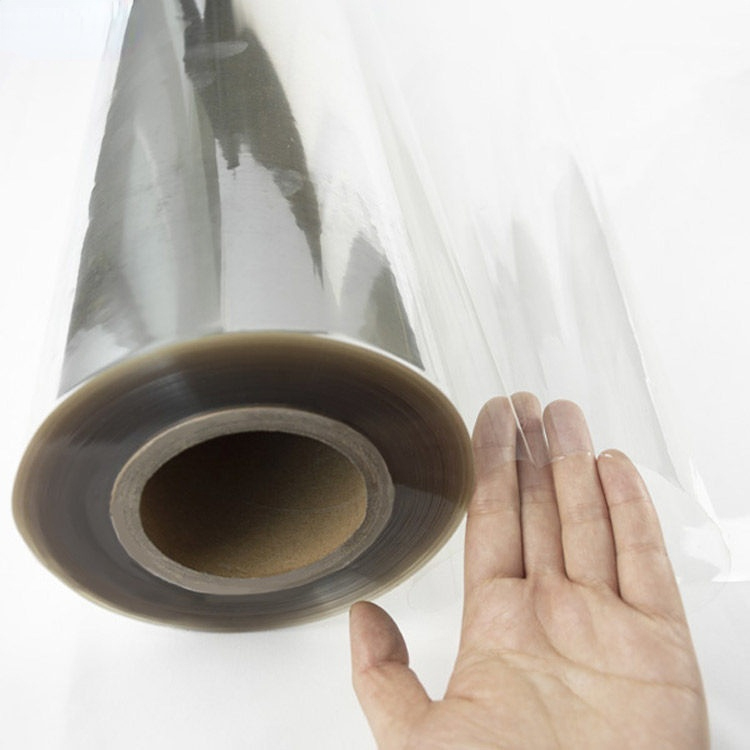

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

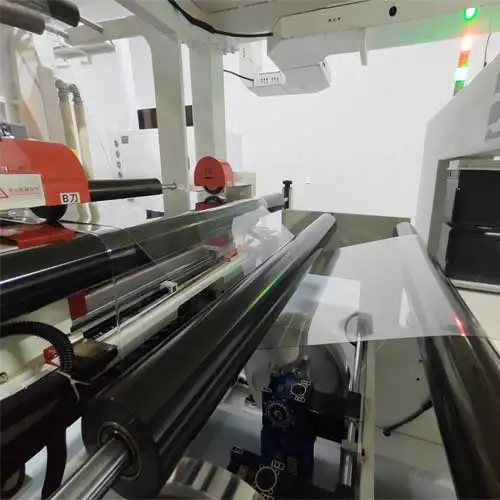

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting |

| Hardness | Rigid/Semi-rigid |

Precautions for PET Plastic Rolls for Drink Cups

When using PET plastic rolls for manufacturing drink cups, there are several important precautions to consider to ensure product quality, safety, and environmental responsibility:

1.Temperature Sensitivity

(1) Avoid High Temperatures: While PET plastic rolls has moderate heat resistance, it should not be exposed to very high temperatures. PET drink cups are typically designed for cold beverages, and prolonged exposure to temperatures above 70°C (158°F) can cause deformation, weakening the cup structure.

(2) Not Suitable for Hot Drinks: PET cups are generally not suitable for hot drinks like coffee or tea, as the heat can cause the plastic to warp or leach chemicals. For hot beverages, alternative materials such as polypropylene (PP) are recommended.

2. Proper Storage of PET Plastic Rolls

(1) Avoid Direct Sunlight: PET plastic rolls should be stored in a cool, dry place, away from direct sunlight. UV exposure can degrade the material, leading to discoloration, loss of clarity, and reduced strength.

(2) Maintain Ideal Storage Conditions: PET plastic rolls should be stored in controlled environments to avoid extreme heat or cold. Temperature fluctuations can affect the roll’s performance during the thermoforming process, causing uneven cup formation or structural issues.

3. Chemical Exposure

(1) Avoid Harsh Chemicals: Although PET has good resistance to most chemicals, it can be affected by certain substances like strong acids, alkalis, and some solvents. Care should be taken to prevent contact with these chemicals during production and storage.

(2) Ensure Compatibility with Beverages: While PET is safe for most beverages, compatibility testing should be done for specialized drinks or additives that may react with the plastic, especially alcoholic or acidic beverages.

4. Thermoforming Process Controls

(1) Monitor Forming Temperatures: During the thermoforming process, ensure the correct temperature is maintained to avoid under- or over-processing. Inconsistent temperatures can result in uneven thickness, cracks, or defects in the finished drink cups.

(2) Control Mold and Tooling Maintenance: Ensure that molds and tools used in thermoforming are properly maintained to avoid defects like burrs or uneven surfaces on the PET cups. Regular cleaning and calibration of equipment are essential.

5. Recycling Considerations

(1) Use of Recycled PET (rPET): When incorporating recycled PET in production, ensure that the material meets food-grade standards. rPET should be processed under strict controls to avoid contamination and ensure product safety.

(2) Labeling for Recycling: Clearly label PET drink cups with the recycling symbol (♳) to encourage proper disposal and recycling by consumers. Improper disposal can contribute to environmental pollution.

6. Food Safety Regulations

(1) Compliance with Food Contact Standards: Ensure that the PET plastic rolls used for drink cups comply with regional food safety regulations, such as the U.S. FDA or European Union food contact materials directives. This ensures that the PET material does not leach harmful chemicals into beverages.

(2) Hygienic Manufacturing Environment: Maintain a clean and hygienic production environment to prevent contamination of PET drink cups. This includes regular sanitation of production areas and adherence to food-grade manufacturing protocols.

7. Transportation and Handling

(1) Prevent Roll Damage: During transportation, handle PET plastic rolls carefully to avoid physical damage such as dents or tears, which could affect the quality of the cups during thermoforming.

(2) Avoid Compression: Store PET plastic rolls in a way that avoids excessive pressure or stacking, as this can lead to deformation or wrinkling of the material, resulting in defects during production.

8. Disposal and Environmental Responsibility

(1) Encourage Proper Disposal: Educate consumers about the recyclability of PET cups and encourage proper disposal to reduce environmental impact. Providing clear recycling instructions on packaging can help.

(2) Minimize Waste in Production: Optimize production processes to reduce scrap and waste. Any excess PET material should be recycled whenever possible to minimize environmental footprint.

While PET plastic rolls offer numerous benefits for drink cup production, careful attention must be paid to handling, processing, and storage to maintain product quality and safety. By adhering to these precautions, manufacturers can ensure the production of durable, safe, and environmentally friendly PET drink cups.

Development Trend of PET plastic Roll for Drink Cups

The use of PET (Polyethylene Terephthalate) plastic rolls in the production of drink cups has evolved significantly due to technological advancements, environmental concerns, and changing consumer preferences. As the demand for sustainable and high-quality packaging solutions grows, PET plastic rolls are expected to play an even greater role in the beverage industry.

Related video- PET plastic rolls production line

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Food Grade PET Plastic Rolls for Thermoforming Packaging

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM