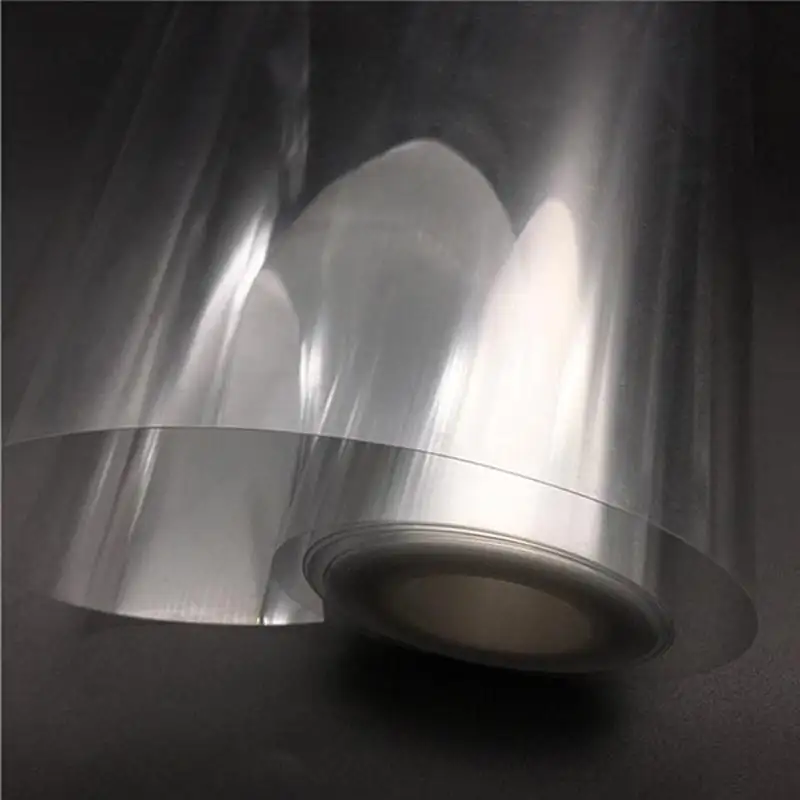

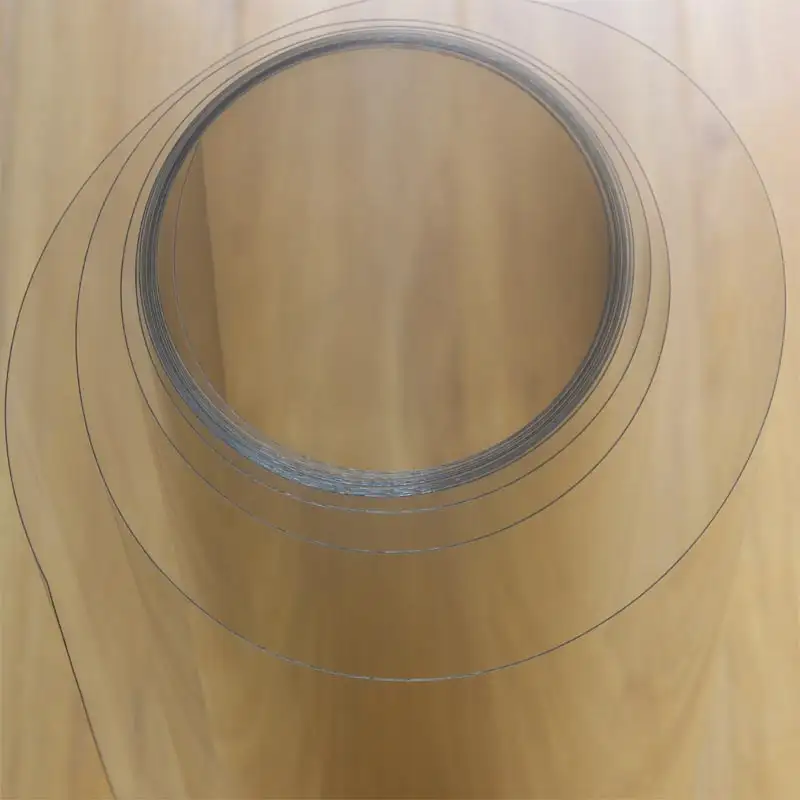

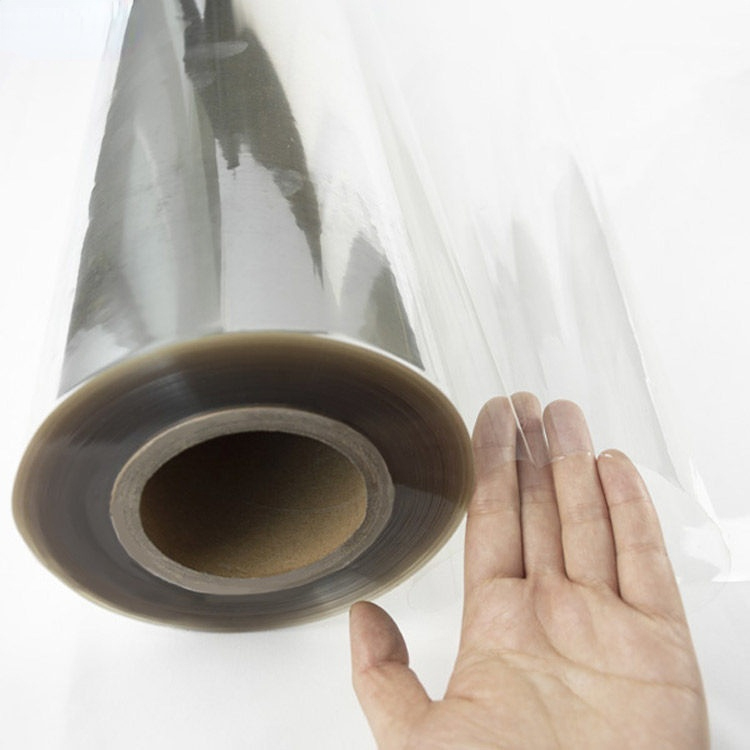

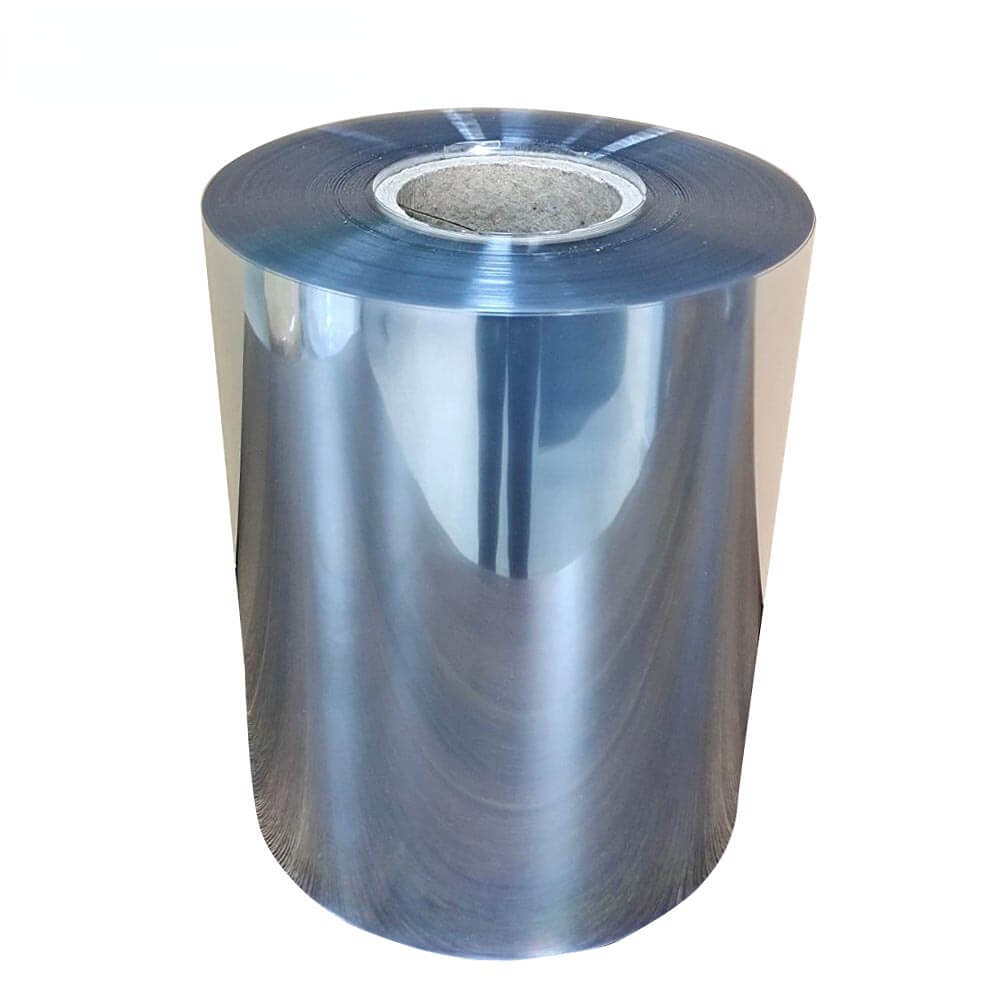

PET plastic sheet rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

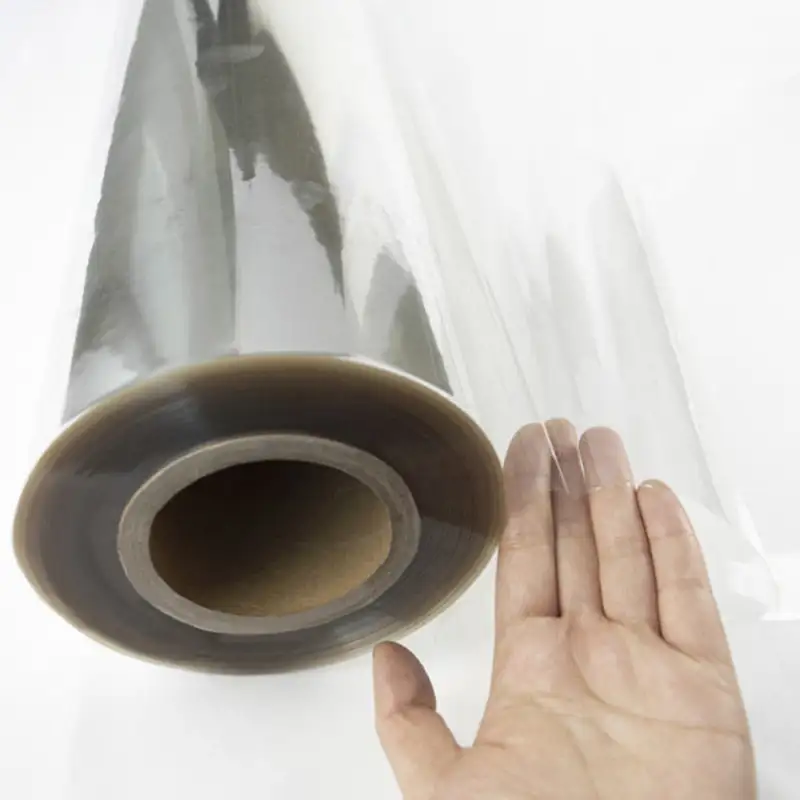

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "PET plastic sheet rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of PET plastic sheet rolls

PET plastic sheet rolls are made from polyethylene terephthalate (PET) and are widely used in various packaging and industrial applications. Their characteristics include:

- Heat Resistance: PET has good heat resistance, suitable for high-temperature processing.

- Transparency: Typically offers excellent transparency, ideal for packaging that requires visual display.

- Strength and Toughness: Exhibits high mechanical strength and toughness, providing protection for internal products.

- Environmental Friendliness: PET is recyclable, aligning with sustainable development trends.

5. Recyclability: PET plastic sheet roll is recyclable, in line with the trend of sustainable development, and is favored by the market and consumers.

PET Plastic Sheet Rolls

- Thickness: 0.18-2.0mm

- Width: 300-1400mm

- Color: Transparent or Customized

- Special performance customization: Anti-fog, Printing, Coating, High impact, Waterproof, Oil-proof, Anti-UV, etc.

- Delivery time: 7~15 days since receipt of PO and down payment.

- Payment Accepted: D/A, D/P, T/T, L/C, Westunion etc.

- Samples: Free samples supply

Common applications include food packaging, electronic product packaging, and other consumer goods packaging.

Advantages of PET plastic sheet rolls

The advantages of PET plastic sheet rolls include:

1. Excellent Clarity: PET plastic sheet rolls has provides high transparency, enhancing product visibility and appeal.

2. Good Barrier Properties: Offers resistance to moisture, gases, and UV light, protecting contents from spoilage and degradation.

3. High Strength and Durability: Withstands impact and puncture, ensuring the safety of packaged goods.

4. Heat Resistance: PET plastic sheet rolls suitable for various applications that require high-temperature processing or storage.

5. Lightweight: Reduces shipping costs and makes handling easier.

6. Recyclability: Can be recycled, contributing to sustainability and reducing environmental impact.

7. Chemical Resistance: Resistant to many chemicals, making it versatile for different applications.

8. Cost-Effectiveness: Provides good performance at a competitive price, making it a popular choice for manufacturers.

These advantages make PET plastic sheet rolls ideal for a wide range of packaging and industrial applications.

Application of PET plastic sheet rolls

PET plastic sheet rolls have the following uses:

1. Blister Packaging: PET plastic rolls are used to create transparent blister packs for items like electronics, medical devices, and food products. They offer a secure yet visible packaging solution.

2. Food Trays and Containers: PET plastic sheet rolls are widely used to produce plastic trays and containers for fresh food, such as fruits, vegetables, and bakery items. They are lightweight and provide a barrier that helps maintain freshness.

3. Beverage Lids: PET plastic sheet rolls can be thermoformed into lids for beverage cups, offering transparency and strength to protect the contents.

4. Pharmaceutical packaging: used in the pharmaceutical industry to package drugs and medical devices to ensure product safety and effectiveness.

5. Cosmetic packaging: used for containers and lids of cosmetics and skin care products, providing good sealing and display effects.

6. Electronic product packaging: protect electronic components and equipment from moisture and damage.

7. Industrial component packaging: used to package mechanical parts and accessories to ensure safety during transportation.

8. Label and sticker packaging: can be used to make water-resistant and wear-resistant label packaging.

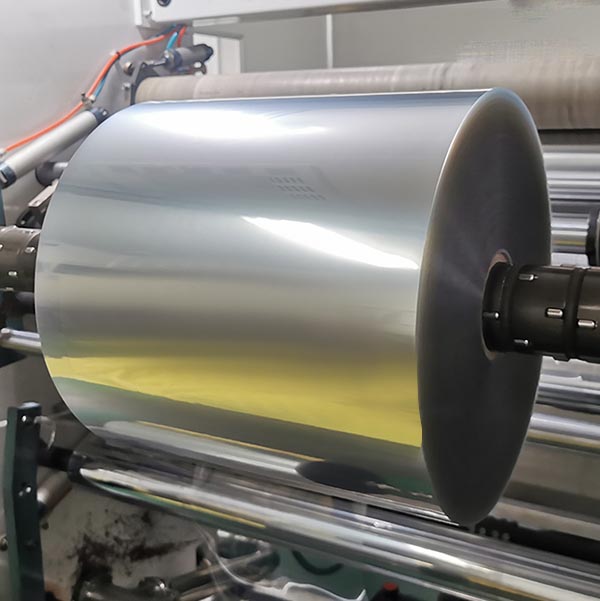

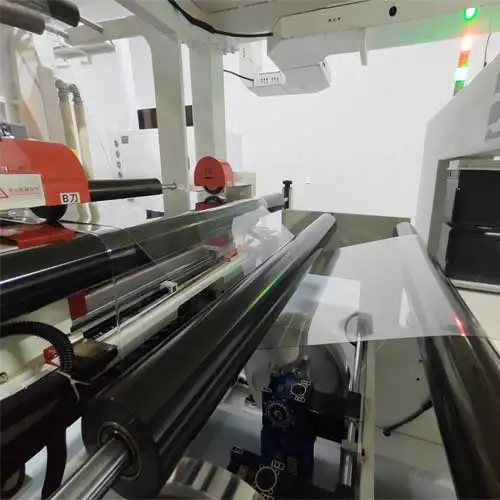

Production and processing of PET plastic sheet rolls

The production and processing of PET (Polyethylene Terephthalate) plastic sheet rolls involve several key steps:

1. Raw Material Preparation: PET resin is produced through a polymerization process, typically from purified terephthalic acid (PTA) and ethylene glycol (EG).

The resin is often in pellet form, which is the starting point for sheet production.

2. Extrusion: The PET pellets are fed into an extruder, where they are heated to a molten state.

The molten PET is then forced through a die to form a continuous sheet.

3. Calendering: The extruded sheet is passed through a series of heated rollers (calenders) to achieve the desired thickness and smoothness.

This process also allows for the adjustment of sheet width.

4. Cooling: The pet palstic sheets are cooled, usually by air or water, to solidify the material and maintain its shape.

5. Trimming and Slitting: After cooling, the edges of the sheets are trimmed, and they are cut into desired widths, resulting in rolls of PET plastic sheet rolls.

6. Quality Control: Samples from the production batch undergo testing for thickness, clarity, strength, and other specifications to ensure quality standards.

7. Packaging and Shipping: The finished PET plastic sheet rolls are packaged for shipment, ensuring protection against moisture and physical damage.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

- 0.7mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM