Pharmaceutical tray packaging – PET plastic sheet rolls

Background

A new generation of Pharmaceutical tray packaging is made of PET plastic sheets to improve the market competitiveness and environmental image of the product. After market research and technical evaluation, the customer determined the following design requirements:

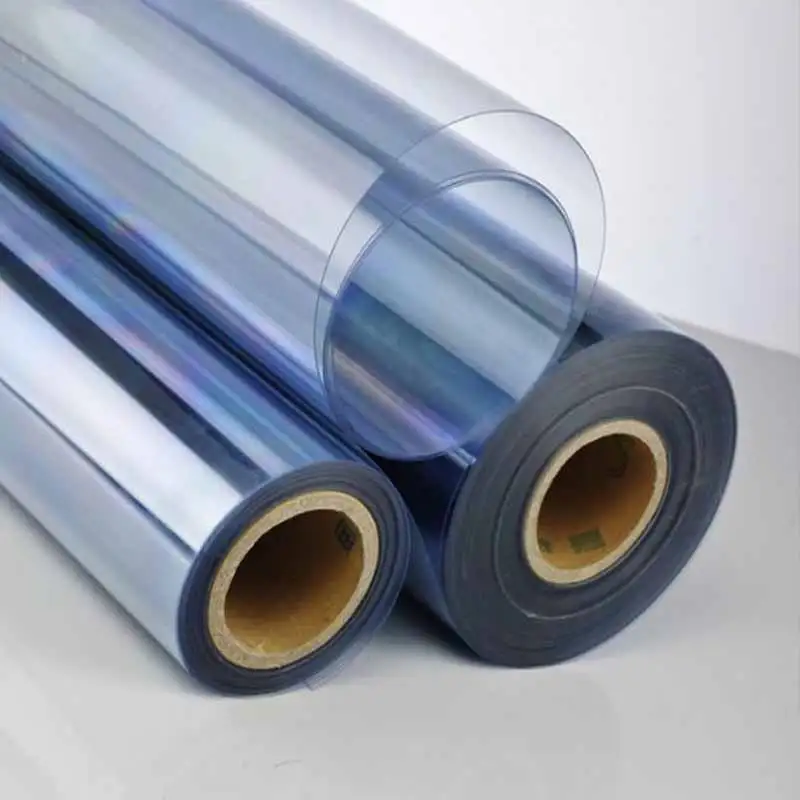

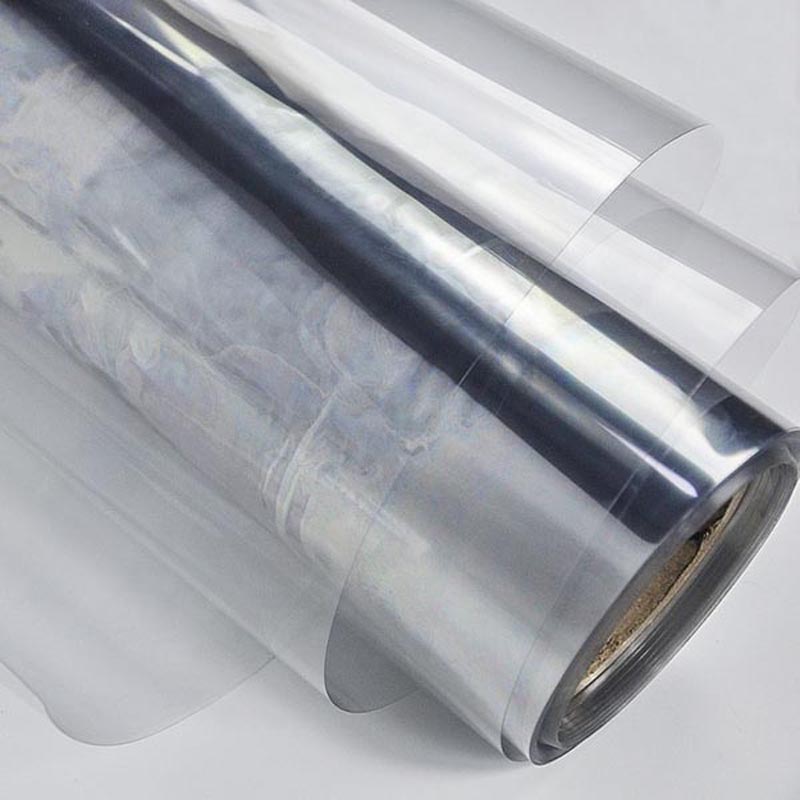

Transparent display effect:

Medicine trays usually need to have good transparency to facilitate the inspection and identification of medicines and ensure the integrity and correctness of medicines before use.

Sterilization and cleanliness:

The tray must be able to withstand high temperature sterilization or other disinfection methods to ensure the sterile environment of the medicine during the packaging process. At the same time, the surface of the tray should be smooth and non-porous to avoid the residue of bacteria or contaminants.

Strength and stability:

The packaging box must be able to withstand physical impact during transportation and storage and is not easy to break.

Environmental protection requirements:

Use recyclable materials to comply with environmental regulations and consumer green consumption needs.

Design and production

After understanding the customer’s needs, our sales team recommended PET plastic sheet rolls and designed a medicine packaging tray with grooves that can safely hold and clearly display each item. Each groove is designed with finger grooves for easy access.

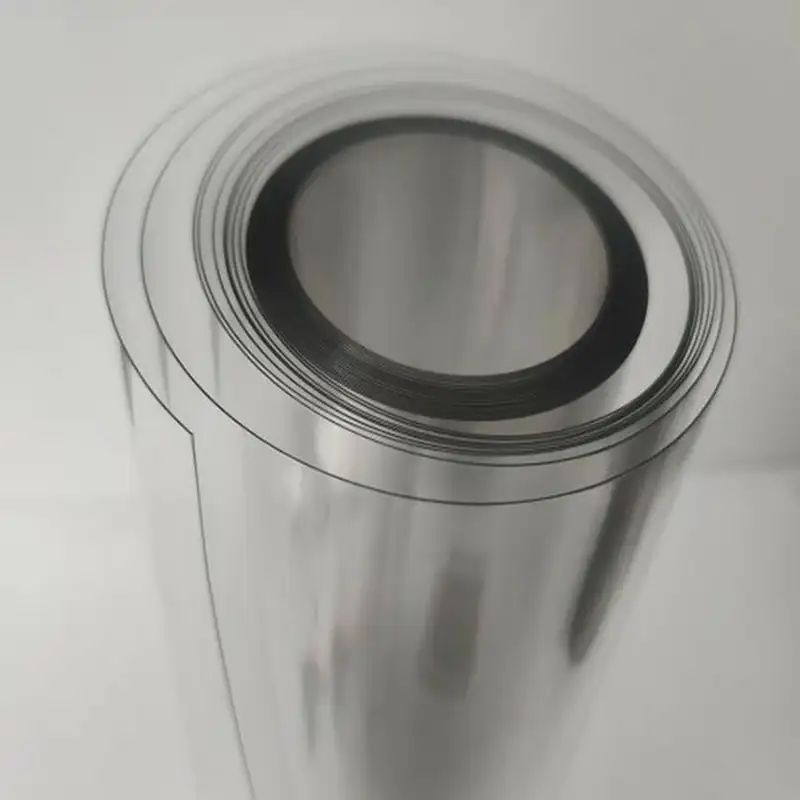

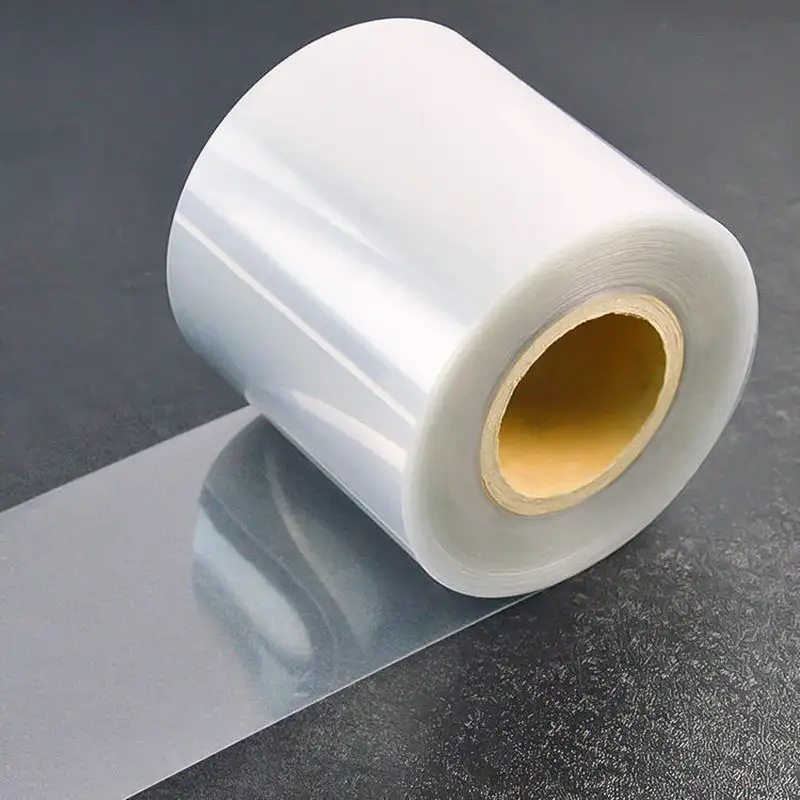

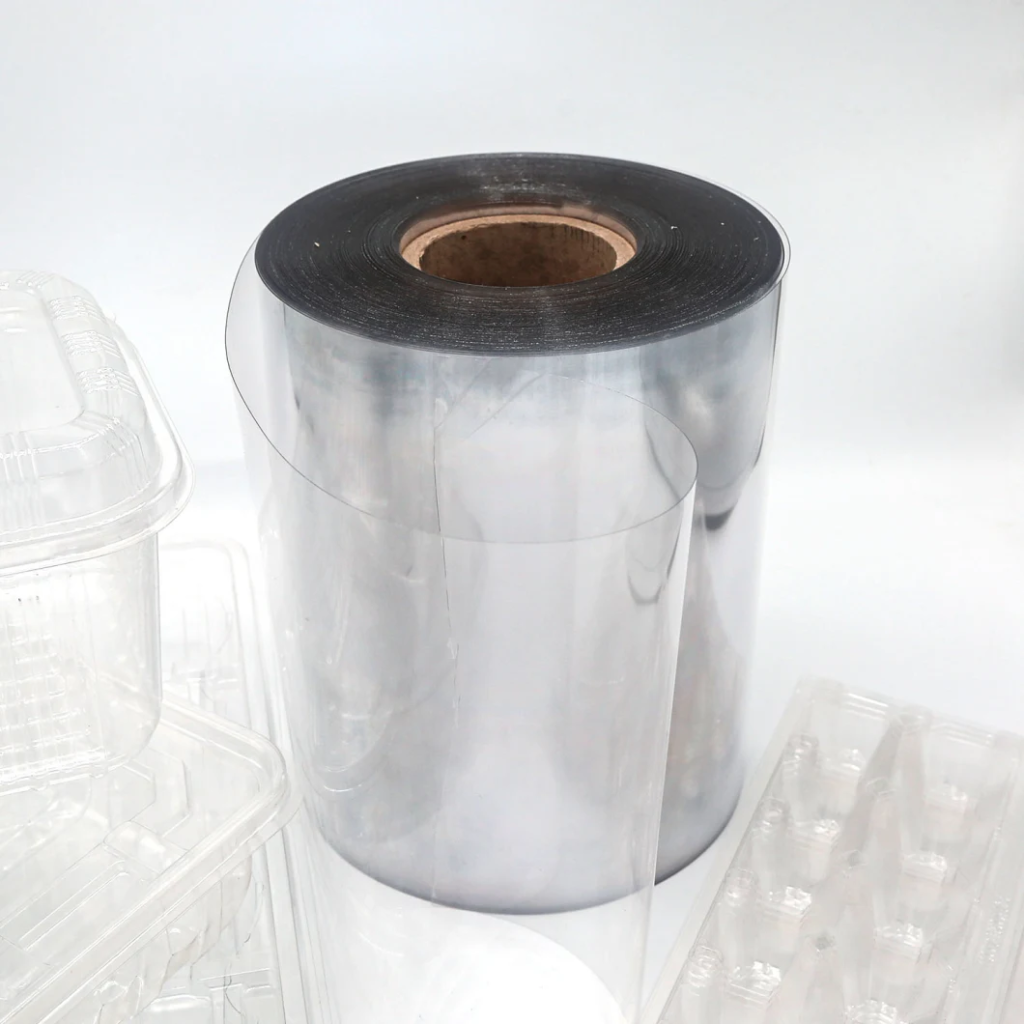

Pharmaceutical Tray Packaging – PET Plastic Sheet Rolls

Material: PET (Polyethylene Terephthalate) Plastic Rolls

Usage: Pharmaceutical Tray Packaging

Unique Features of PET Plastic Sheet Rolls for Pharmaceutical Tray Packaging

In addition to meeting the above needs of customers, our PET Plastic Rolls can also provide customers with the following advantages, which can better meet customer needs in an all-round way.

Sterilization Compatibility:

PET plastic roll is compatible with various sterilization methods, including gamma radiation, E-beam, and ethylene oxide (EtO), making it suitable for pharmaceutical applications that require sterile packaging.

Chemical Resistance:

PET plastic roll provides strong resistance to many chemicals, ensuring that the tray packaging does not react with the pharmaceutical products, maintaining the integrity and safety of the medications.

Excellent Barrier Properties:

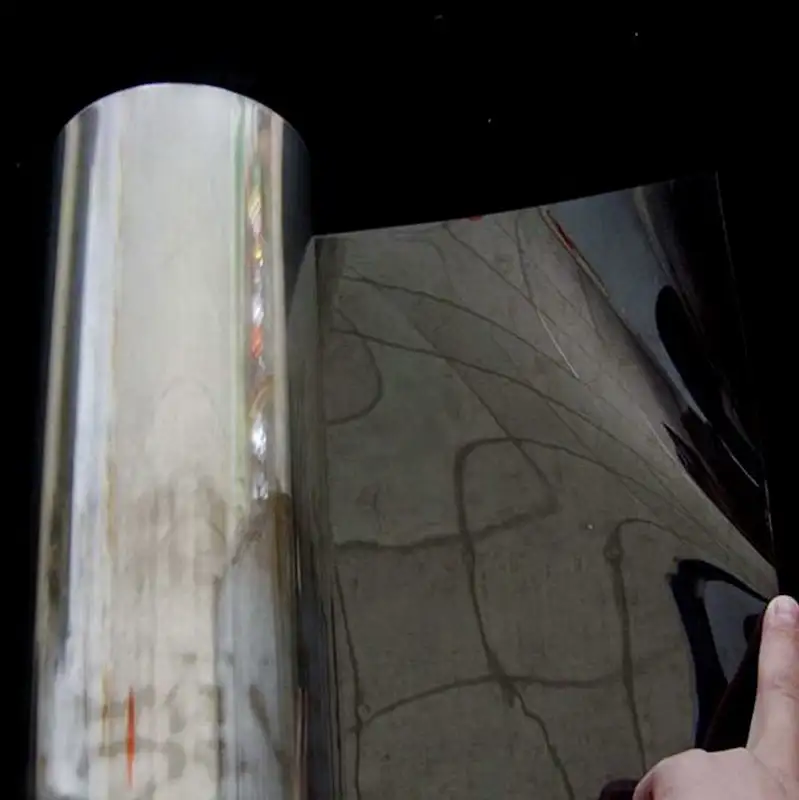

PET plastic sheet rolls offer a strong barrier against moisture and gases, which is essential for protecting pharmaceuticals from environmental factors that could compromise their efficacy or shelf life.

Lightweight:

Despite its strength, PET plastic roll is lightweight, making it easier and more cost-effective to transport pharmaceutical products.

Customization:

PET plastic sheet rolls can be easily thermoformed into various tray shapes and sizes, tailored to specific pharmaceutical products, whether for individual doses, vials, syringes, or blister packs.

Safety and Compliance:

PET plastic roll is a food and medical-grade material that meets stringent regulatory requirements, making it safe for pharmaceutical use. It complies with global standards, including FDA and EU regulations.

Tamper-Evident Features:

PET plastic roll can be designed to include tamper-evident features, providing an additional layer of security for pharmaceutical products, ensuring that they have not been altered or compromised before reaching the end-user.

Results and feedback

These unique features make PET plastic sheet rolls an ideal material for manufacturing pharmaceutical tray packaging, ensuring the safety, integrity, and visibility of pharmaceutical products throughout their lifecycle.

More Product Recommendations

In addition to providing you with ordinary PET plastic sheet rolls, we can also provide you with PET plastic rolls of other properties and sizes. We look forward to your consultation.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM