The Basic Knowledge Of Plastic PP

August 1, 2024

News

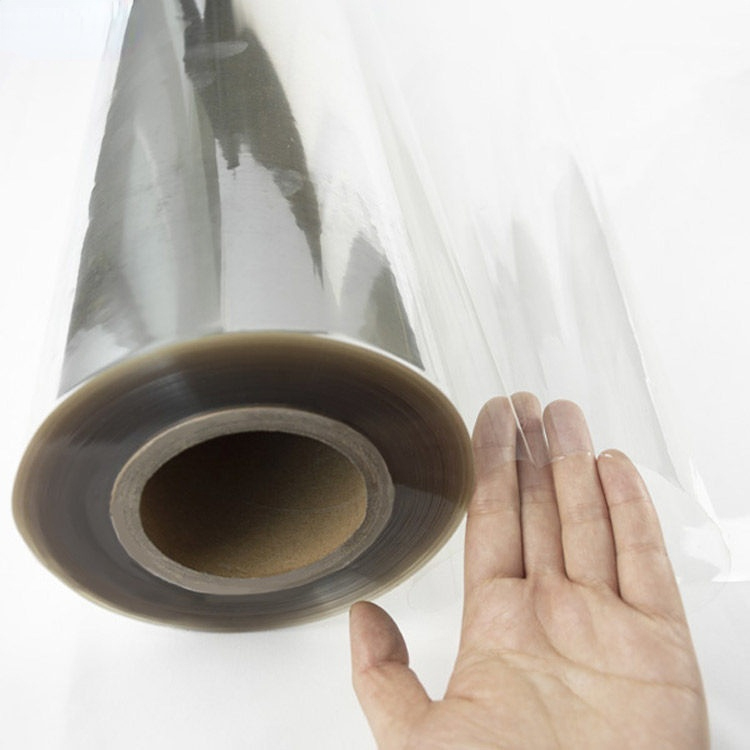

Polypropylene (PP) material is a polymer made from propylene through a polymerization reaction. It is a white waxy material, transparent and light in appearance. Chemical formula is (C3H6)n. Flammable, melting point 189℃, softening at 155℃, use temperature range is -30~140℃. It can resist the corrosion of acid, alkali, salt liquid and many kinds of organic solvents below 80℃, and can decompose under the effect of high temperature and oxidation. Polypropylene is widely used in the production of garments, blankets and other fiber products, medical equipment, automobiles, bicycles, parts, conveying pipes, chemical containers, etc. It is also used in food and drug packaging. Picture

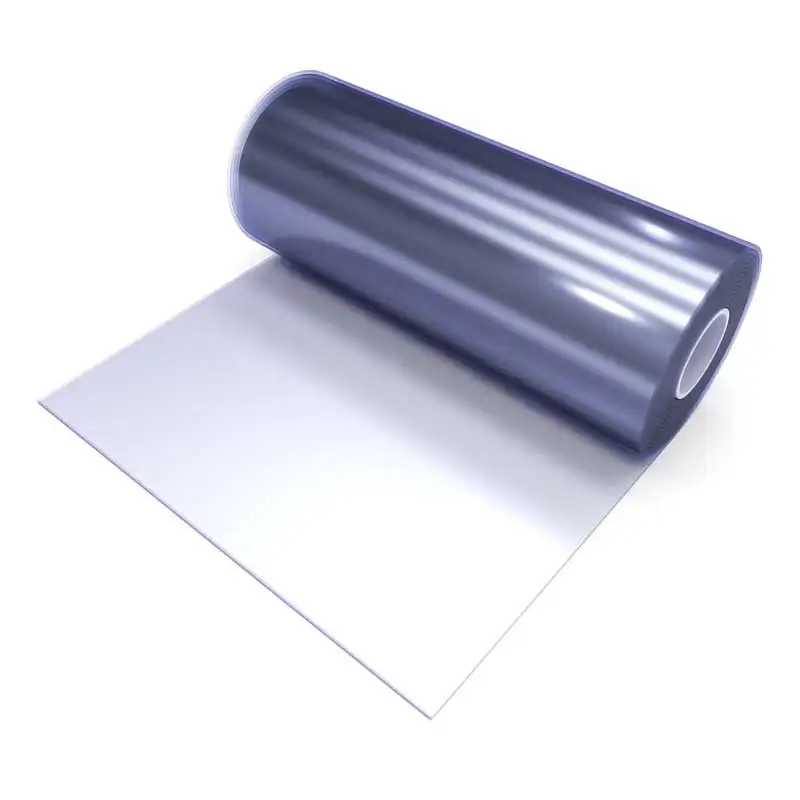

Transparent PP plastic

Plastic, is a resin as the main component, with plasticizers, fillers, lubricants, colorants and other additives as auxiliary components. PP materials have chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and high wear resistance processing properties. However, for poor impact resistance at low temperatures and poor weather resistance of polypropylene, it is modified to expand the scope of use.

1,PP physical properties

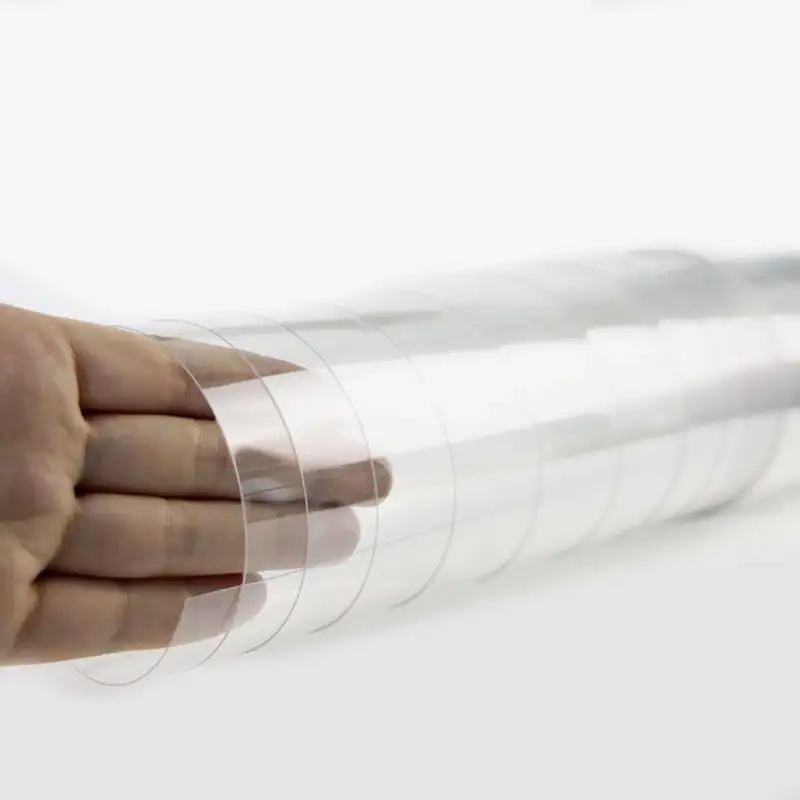

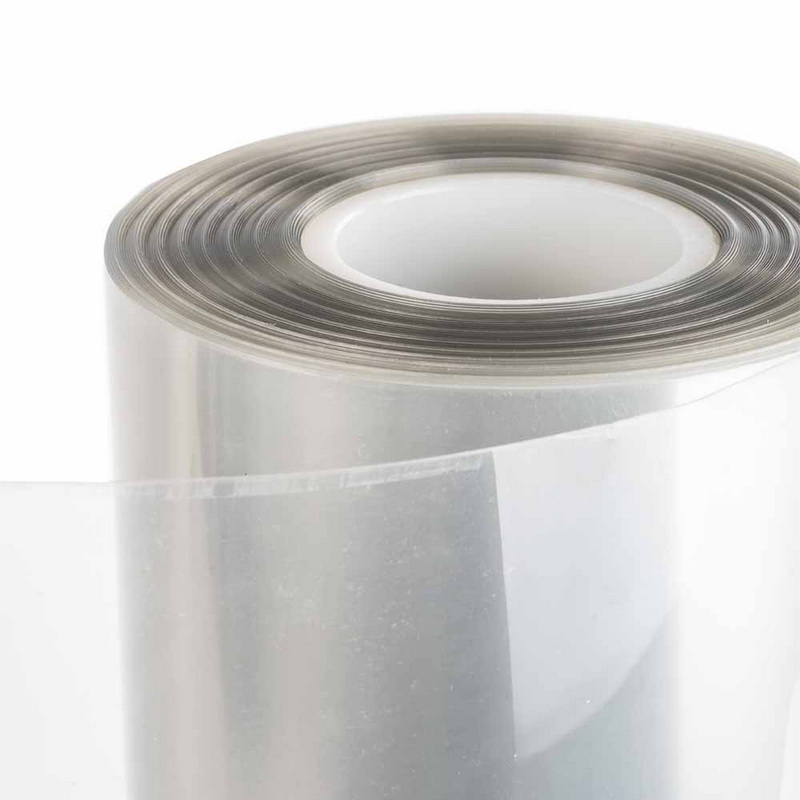

Non-toxic, odorless, tasteless, milky white, highly crystalline polymer with a relative molecular mass of about 8-15 million. Material shrinkage rate 1.5%-2.2%. Small density: 890-910kg/m3, one of the lightest varieties of plastic. Strong hydrophobicity: water absorption rate in water for 24h is only 0.01%. Good formability, but large shrinkage rate, thick-walled products are easy to dent. Good surface gloss, easy to color.

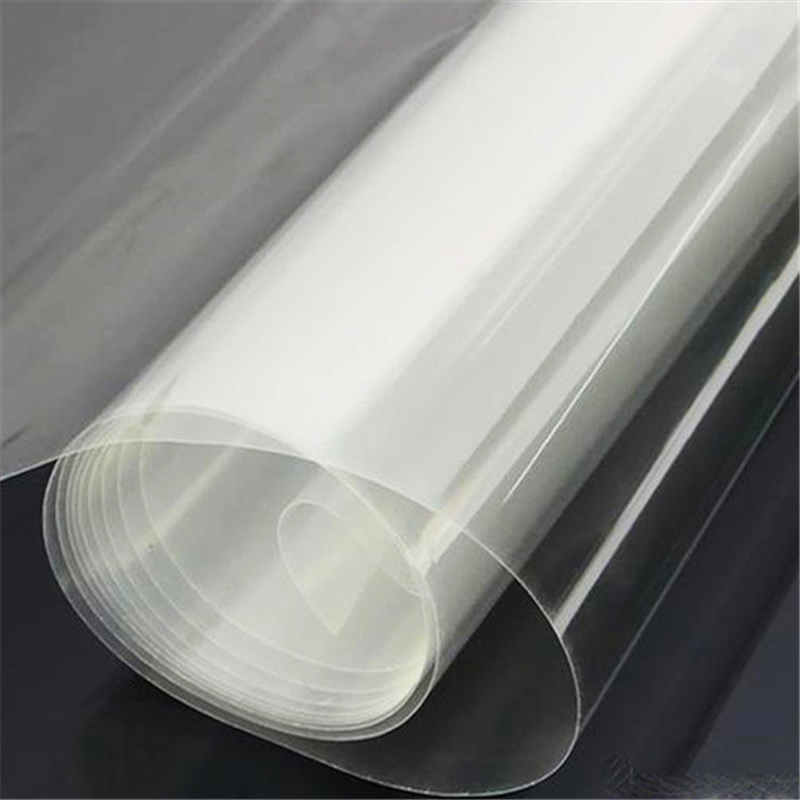

Transparent PP plastic

Plastic, is a resin as the main component, with plasticizers, fillers, lubricants, colorants and other additives as auxiliary components. PP materials have chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and high wear resistance processing properties. However, for poor impact resistance at low temperatures and poor weather resistance of polypropylene, it is modified to expand the scope of use.

1,PP physical properties

Non-toxic, odorless, tasteless, milky white, highly crystalline polymer with a relative molecular mass of about 8-15 million. Material shrinkage rate 1.5%-2.2%. Small density: 890-910kg/m3, one of the lightest varieties of plastic. Strong hydrophobicity: water absorption rate in water for 24h is only 0.01%. Good formability, but large shrinkage rate, thick-walled products are easy to dent. Good surface gloss, easy to color.

2,Mechanical properties

PP has high crystallinity and regular structure, so it has excellent mechanical properties. The most outstanding property of PP is its resistance to bending fatigue.

3,Thermal performance

PP has good heat resistance, the product can be sterilized at a temperature above 100℃, and does not deform at 150℃ under the condition of no external force. Embrittlement temperature is -35℃, embrittlement will occur below -35℃, cold resistance is not as good as PE and other gauge increase or molecular weight reduction is conducive to the improvement of thermal performance.

4,Chemical stability

The chemical stability of PP is very good, except for concentrated sulfuric acid, concentrated nitric acid erosion, to a variety of other chemical reagents are relatively stable; but low molecular weight of aliphatic hydrocarbons, aromatic hydrocarbons and chlorinated hydrocarbons can make polypropylene softening and swelling, while its chemical stability with the increase in crystallinity has also improved, so PP is suitable for making a variety of chemical pipes and fittings, good corrosion prevention.

5,Electrical performance

PP has excellent high-frequency insulation performance, and because it hardly absorbs water, the insulation performance is not affected by humidity. It has a high dielectric coefficient, and with the rise of temperature, it can be used to make electrical insulation products subject to heat. It also has a high breakdown voltage, which makes it suitable for use as electrical fittings, etc. It has good resistance to voltage and arc, but high static electricity. The presence of side methyl groups in PP causes alternating tertiary carbon atoms on the molecular chain, which are highly susceptible to oxidation reactions when in contact with copper ions, resulting in poor oxidation and radiation resistance of polypropylene. Therefore, copper inhibitors must be added for use in contact with copper.

6,Weather resistance

PP is sensitive to ultraviolet light and needs to add additives to improve its aging resistance. Commonly used are UV absorbers and UV quenching agents, etc. PP-TD20 is an enhanced modified material of PP material, TD20 is 20% talcum powder, which means 20% talcum powder filling.

7,High temperature performance

Specimen (150±2) × (70±2) × (3.2±0.2) mm × 3 pieces, PP material at 90±2°C, the shape and surface are not allowed to damage the change of performance, no discoloration. PP-TD20 at 110±2°C, the shape and surface are not allowed to damage the change of performance, no discoloration.

8,Low temperature performance

Specimen (150±2) × (70±2) × (3.2±0.2) mm × 3 pieces, test temperature at (-40±2) °C storage time of (24±2) h, and then immediately after heating to (23±2) °C, the sample does not appear cracks and other defects.

9,Heat resistance aging

Test in accordance with GB/T 7141 test method, size (150±2) × (70±2) × (3.2±0.2) mm × 3 specimens in (150±2) ° C circulating air, the specific requirements of the specimen and the parts of the ambient temperature, such as cabin > = 1000h, near the cabin parts > = 700h, other parts > = 400h.

10,Light aging resistance

Specific and parts affected by the intensity of sunlight, the horizontal and vertical surface, etc.

11,Scratch resistance

According to the method specified in Q/JLY J7110536, Δ<=1.5 (load 10N, scratch head 1.0mm).

12.Burning performance

According to Q/JLY J7110335B-2019, the burning rate is required to be 80mm/min.CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM