The Worlds Most Useful Plastics PET And Polyester

August 1, 2024

News

Polyethylene terephthalate (PETE or PET) is the world’s most commonly used thermoplastic polymer, known in the textile industry by the trade name “polyester”. It is a naturally clear, semi-crystalline plastic that is widely used as a garment fiber, an effective moisture barrier, widely used in bottling and packaging (in these cases called PET or “PET resin”), and as an engineering plastic that can significantly improve the strength of materials when combined with other materials such as glass fibers or carbon nanotubes. It is a naturally colorless, semi-crystalline material. Some of its most important properties include its water resistance, its high strength-to-weight ratio, the fact that it is virtually shatterproof (it does not break like glass packaging), and its wide availability as an economical and recyclable plastic (resin identification code “1”).

PET was first polymerized in the 1940s by DuPont chemists to develop a polymeric material for textile fibers. It is synthesized from ethylene glycol and terephthalic acid. Even without additives to increase its strength, PET is still very strong due to its light weight. This means that less material is needed for applications such as plastic film for packaging. This means that less fuel is required for transportation when using PET for packaging. In addition, even though the material is petroleum-based, about 40 percent of the energy is stored internally and can be reused after recycling. According to PETresin.org, “Life cycle studies of PET have consistently shown it to be a highly sustainable material with positive environmental benefits.”

According to some reports, the current global demand for this material generates a market of approximately 56 million tons per year. The main end-user of polypropylene is the textile industry, which (according to Wikipedia) consumes about 60 percent of the total. Other major uses include the bottling and packaging industry, which accounts for about 30%.

Some of the most important properties of polyethylene terephthalate (PETE or PET) are

Chemical resistance: PET does not react with water or food, which is one of the reasons it is used in consumable packaging.

Strength-to-weight ratio: PET is very strong due to its light weight.

Shatterproof: PET will not break or fracture. This makes it a great alternative to glass containers.

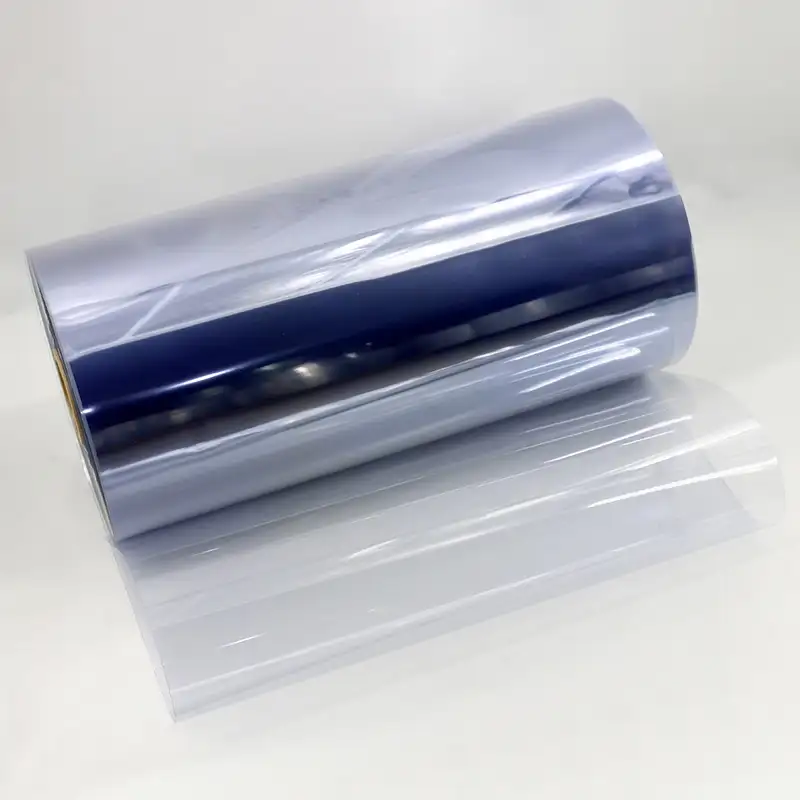

Transmittance: Polyethylene terephthalate (PETE or PET) is naturally transparent. That said, if high translucency is required, plastics such as acrylic or polycarbonate may be a better choice.

Polyethylene terephthalate is usually a “thermoplastic” (as opposed to “thermoset”) material, which is related to the way the plastic reacts to heat. That said, some variants of the material (such as certain types of polyesters) are thermosetting. Thermoplastic materials become liquid at their melting point (in the case of PET, about 260 degrees Celsius). One of the main useful properties of thermoplastics is that they can be heated to their melting point, cooled and reheated without significant degradation. Thermoplastics such as polypropylene do not burn, but rather liquefy, which makes them easy to injection mold and then subsequently recycle. In contrast, thermoset plastics can only be heated once (usually during the injection molding process). The first heating causes the thermoset material to solidify (similar to a two-part epoxy resin), resulting in a chemical change that cannot be reversed. If you try to heat a thermoset plastic to a high temperature again, it will just burn. This property makes thermosets a poor candidate for recycling.

Why is polyethylene terephthalate (PETE or PET) often used?

PET is unique in that it is virtually shatterproof, has an extremely high strength-to-weight ratio, and does not react with food or water. In addition to its wide availability and low price, the combination of these material properties makes it an almost unbeatable packaging solution for consumer products. Polyester for fabrics is strong and flexible, and when used in combination with materials such as cotton, it reduces wrinkling and shrinkage and makes fabrics more resistant to tearing. That’s why PET materials can be used for many folding box applications.

Is PET toxic?

No. PET is an environmentally friendly material and is widely accepted by health authorities as a safe plastic, which is one of the reasons it is so commonly used in food and beverage packaging. Similar to glass, it is hygienic and generally resistant to attack by bacteria and other microorganisms. It does not biodegrade, even when in direct contact with food and beverages. Special variants of take-home plastic containers made from PET are also available for microwavable foods and are FDA-approved for single-use and reuse.

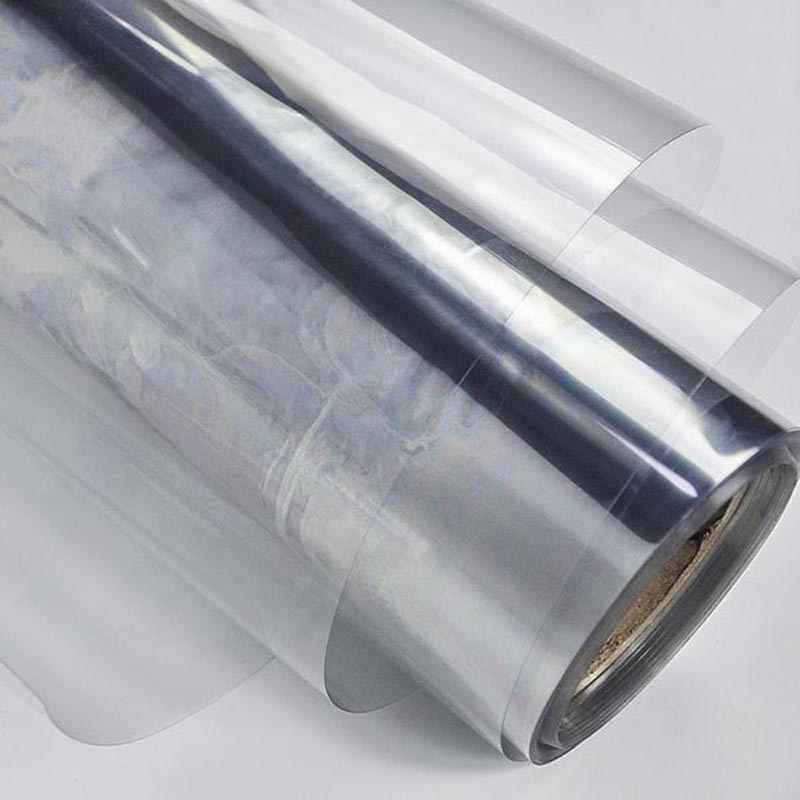

PET plastic sheet is a thermoplastic and environmentally friendly plastic material. It is odorless and tasteless when burned and does not produce toxic gases. It can be used in many fields such as blistering, packaging, printing and folding boxes. With its low price and high transparency, it is gradually replacing PVC material as one of the most common general-purpose plastics.

Desu Technology Co,. Ltd is a leading manufacturer of PET and PETG plastics, we offer a wide range of PET plastics such as transparent PET sheet, UV-protected PET sheet, color PET sheet, color PETG sheet, laminated PET sheet, etc.

1. Good transparency and glossy surface.

2. Friendly to the environment and recyclable.

3. Competitive price.

4. Excellent physical properties.

5. Good chemical resistance.

If you need PET as a material, Desu Technology Co,. Ltd is proud to produce it for you.

We understand that plastics are deeply integrated into our global economy and touch almost every aspect of our lives. We must address the plastic waste problem in a targeted way. Because it plays such an important and necessary role in today’s world, we must focus our attention on changing plastic for the betterment of our planet.

We believe that the only footprint we should leave behind is our own. That’s why we are relentless in our quest to retain all the positive benefits of plastic while putting an end to global plastic waste.

PET was first polymerized in the 1940s by DuPont chemists to develop a polymeric material for textile fibers. It is synthesized from ethylene glycol and terephthalic acid. Even without additives to increase its strength, PET is still very strong due to its light weight. This means that less material is needed for applications such as plastic film for packaging. This means that less fuel is required for transportation when using PET for packaging. In addition, even though the material is petroleum-based, about 40 percent of the energy is stored internally and can be reused after recycling. According to PETresin.org, “Life cycle studies of PET have consistently shown it to be a highly sustainable material with positive environmental benefits.”

According to some reports, the current global demand for this material generates a market of approximately 56 million tons per year. The main end-user of polypropylene is the textile industry, which (according to Wikipedia) consumes about 60 percent of the total. Other major uses include the bottling and packaging industry, which accounts for about 30%.

Some of the most important properties of polyethylene terephthalate (PETE or PET) are

Chemical resistance: PET does not react with water or food, which is one of the reasons it is used in consumable packaging.

Strength-to-weight ratio: PET is very strong due to its light weight.

Shatterproof: PET will not break or fracture. This makes it a great alternative to glass containers.

Transmittance: Polyethylene terephthalate (PETE or PET) is naturally transparent. That said, if high translucency is required, plastics such as acrylic or polycarbonate may be a better choice.

Polyethylene terephthalate is usually a “thermoplastic” (as opposed to “thermoset”) material, which is related to the way the plastic reacts to heat. That said, some variants of the material (such as certain types of polyesters) are thermosetting. Thermoplastic materials become liquid at their melting point (in the case of PET, about 260 degrees Celsius). One of the main useful properties of thermoplastics is that they can be heated to their melting point, cooled and reheated without significant degradation. Thermoplastics such as polypropylene do not burn, but rather liquefy, which makes them easy to injection mold and then subsequently recycle. In contrast, thermoset plastics can only be heated once (usually during the injection molding process). The first heating causes the thermoset material to solidify (similar to a two-part epoxy resin), resulting in a chemical change that cannot be reversed. If you try to heat a thermoset plastic to a high temperature again, it will just burn. This property makes thermosets a poor candidate for recycling.

Why is polyethylene terephthalate (PETE or PET) often used?

PET is unique in that it is virtually shatterproof, has an extremely high strength-to-weight ratio, and does not react with food or water. In addition to its wide availability and low price, the combination of these material properties makes it an almost unbeatable packaging solution for consumer products. Polyester for fabrics is strong and flexible, and when used in combination with materials such as cotton, it reduces wrinkling and shrinkage and makes fabrics more resistant to tearing. That’s why PET materials can be used for many folding box applications.

Is PET toxic?

No. PET is an environmentally friendly material and is widely accepted by health authorities as a safe plastic, which is one of the reasons it is so commonly used in food and beverage packaging. Similar to glass, it is hygienic and generally resistant to attack by bacteria and other microorganisms. It does not biodegrade, even when in direct contact with food and beverages. Special variants of take-home plastic containers made from PET are also available for microwavable foods and are FDA-approved for single-use and reuse.

PET plastic sheet is a thermoplastic and environmentally friendly plastic material. It is odorless and tasteless when burned and does not produce toxic gases. It can be used in many fields such as blistering, packaging, printing and folding boxes. With its low price and high transparency, it is gradually replacing PVC material as one of the most common general-purpose plastics.

Desu Technology Co,. Ltd is a leading manufacturer of PET and PETG plastics, we offer a wide range of PET plastics such as transparent PET sheet, UV-protected PET sheet, color PET sheet, color PETG sheet, laminated PET sheet, etc.

1. Good transparency and glossy surface.

2. Friendly to the environment and recyclable.

3. Competitive price.

4. Excellent physical properties.

5. Good chemical resistance.

If you need PET as a material, Desu Technology Co,. Ltd is proud to produce it for you.

We understand that plastics are deeply integrated into our global economy and touch almost every aspect of our lives. We must address the plastic waste problem in a targeted way. Because it plays such an important and necessary role in today’s world, we must focus our attention on changing plastic for the betterment of our planet.

We believe that the only footprint we should leave behind is our own. That’s why we are relentless in our quest to retain all the positive benefits of plastic while putting an end to global plastic waste.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM