Why Choose PET Plastic Rolls for Model Kit Packaging?

PET plastic rolls are an excellent choice for model kit packaging

When it comes to packaging model kits, choosing the right material is crucial for ensuring product safety, durability, and appeal. One material that has consistently proven its worth in the packaging industry is PET (Polyethylene Terephthalate) plastic. Here’s why PET plastic rolls are an excellent choice for model kit packaging:

1. Superior Strength and Durability

PET plastic is known for its robustness and resistance to impact. This makes it an ideal choice for protecting delicate model kits from physical damage during transportation and storage. Whether it’s small plastic parts or intricate components, PET rolls offer reliable protection.

2. Lightweight Yet Sturdy

Despite its strength, PET plastic is lightweight, which reduces shipping costs and makes handling easier. It ensures that model kits are protected without adding significant weight to the packaging, offering both efficiency and cost savings.

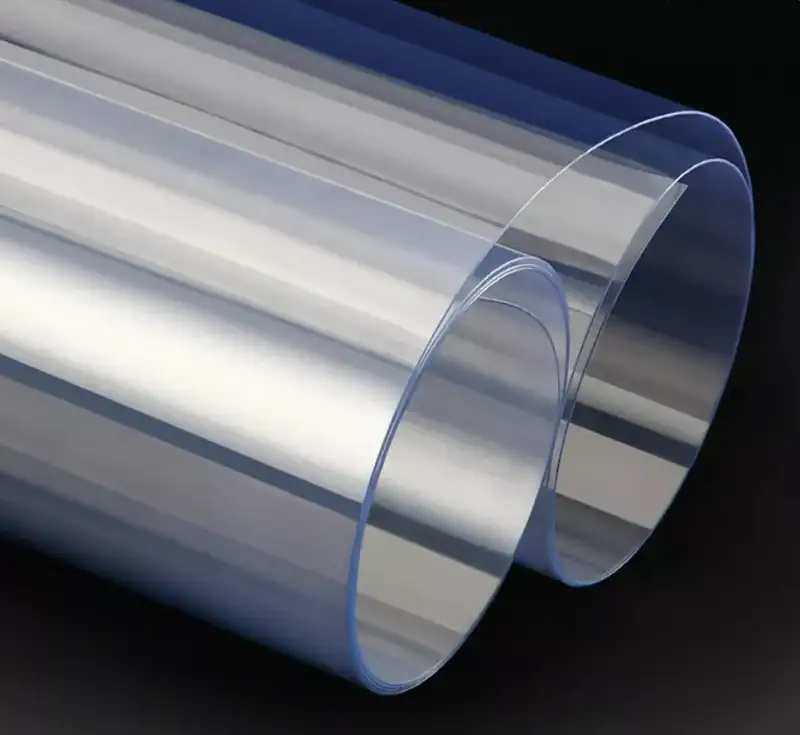

3. Transparency for Display

One of the most attractive features of PET plastic is its crystal-clear transparency. This provides customers with a full view of the product inside the packaging. For model kits, where visual appeal is key, transparent PET packaging allows customers to inspect the kit before purchase while keeping it secure.

4. Environmental Sustainability

PET plastic is highly recyclable, making it a more eco-friendly choice compared to many other packaging materials. With growing consumer concern about sustainability, using recyclable materials like PET can improve your brand image and appeal to environmentally-conscious customers.

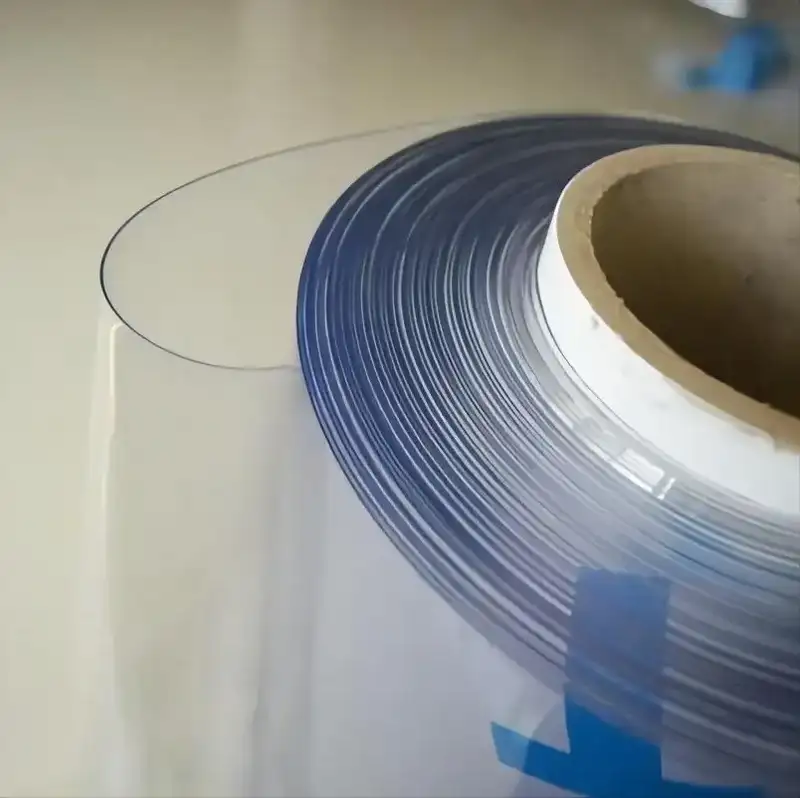

5. Customizable and Versatile

PET rolls can be easily customized in terms of size, thickness, and design. This flexibility makes it ideal for various types of model kits, whether they are toys, collectibles, or DIY projects. Furthermore, PET can be molded into different shapes or printed with logos and product information for a personalized touch.

6. Protection Against Moisture

PET plastic provides an excellent barrier against moisture and dust, preventing environmental factors from damaging model kits. This makes it especially beneficial in regions with high humidity or during long-term storage, keeping the model kits in pristine condition.

7. Cost-Effective Solution

While offering high-quality protection and visual appeal, PET plastic rolls are also cost-effective compared to other packaging materials. The combination of affordable pricing and excellent performance makes PET a budget-friendly solution for packaging model kits, especially for large-scale production.

Conclusion

Choosing PET plastic rolls for model kit packaging not only ensures protection, durability, and aesthetic appeal, but it also provides an environmentally responsible and cost-effective solution. Whether you’re a manufacturer or retailer, PET plastic rolls offer unmatched versatility and performance, making them the go-to packaging material for model kits worldwide.

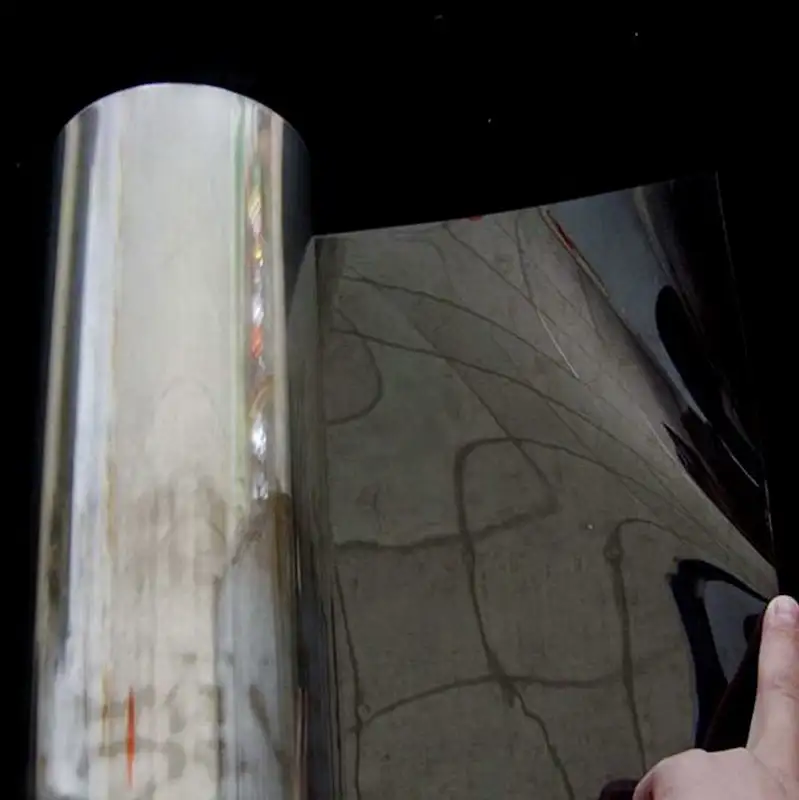

What is PET plastic rolls?

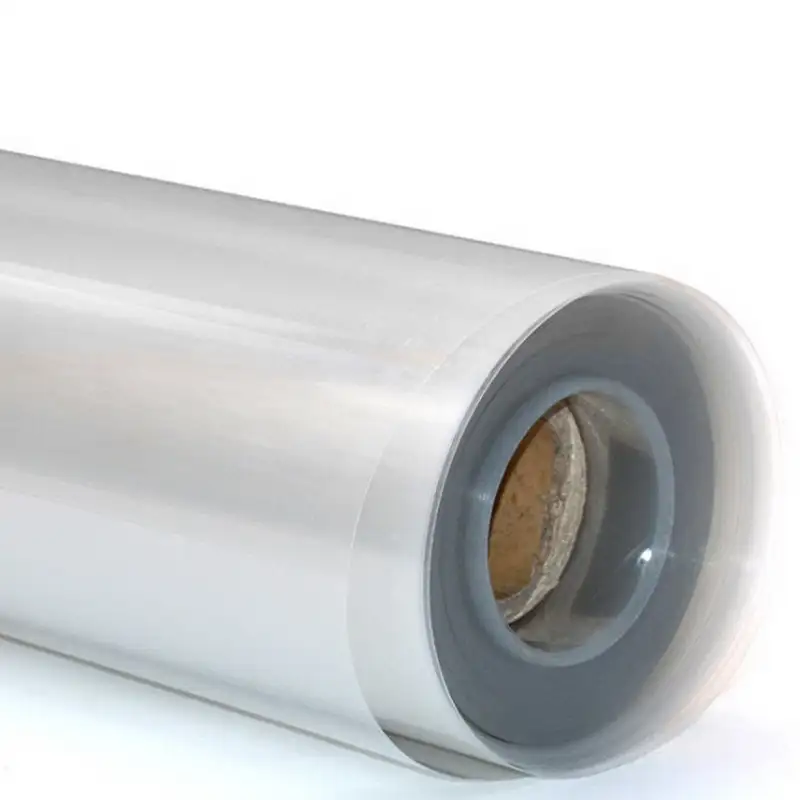

PET plastic rolls are flexible sheets made from Polyethylene Terephthalate (PET), a strong and lightweight thermoplastic material. These rolls are commonly used in various industries for packaging, as well as for producing thermoformed products.

PET plastic rolls are known for its excellent strength-to-weight ratio, clarity, and durability, making it an ideal material for protecting items during shipping and storage. The transparent nature of PET allows for clear visibility of the packaged product, which is particularly useful for retail packaging.

In addition to their use in packaging, PET plastic rolls are valued for their recyclability, offering an environmentally-friendly solution. They are resistant to moisture, dust, and other environmental factors, making them suitable for a wide range of applications, from food and cosmetic packaging to electronics and model kit packaging.

PET plastic rolls can be easily customized to meet specific requirements, such as varying thickness, size, and design, making them a versatile and cost-effective choice for manufacturers and businesses worldwide.

We can provide products

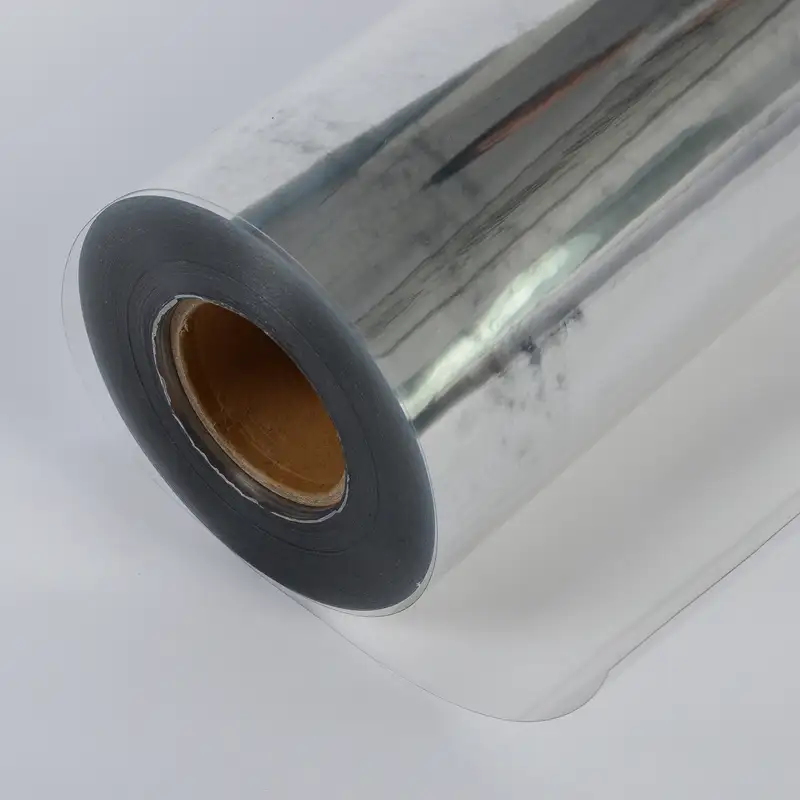

Desu (pet-sheet.com) is a leading manufacturer of PET plastic sheet rolls, offering a wide range of products designed to meet the diverse needs of our customers. Below are some of the products we can provide:

Standard PET Plastic Sheet Rolls: Clear, durable, and lightweight sheets ideal for a variety of packaging applications, including food, electronics, and retail products.

Customized PET Sheet Rolls: Tailored to specific size, thickness, and design requirements. We offer custom solutions for clients looking to create unique packaging or product displays.

Thermoforming Sheet Rolls: High quality PET sheets designed for thermoforming applications, including trays, containers, and blister packs. These sheets are heat-resistant and capable of being molded into various shapes.

Colored PET Plastic Sheet Rolls: In addition to clear sheets, we offer PET sheets in a variety of colors for more visually appealing packaging and applications.

Anti-Static PET Plastic Sheet Rolls: These sheets are specifically designed to protect sensitive electronic components by preventing static build-up during transportation and storage.

Food-Grade PET Plastic Sheet Rolls: Perfect for food packaging, offering high transparency, moisture resistance, and protection against contaminants.

UV-Coated PET Plastic Sheet Rolls: These sheets are coated with a UV protective layer, providing enhanced durability and protection against sunlight exposure for outdoor applications.

Our products are available in various thicknesses and sizes to meet the specific needs of our customers, and we offer both standard and custom solutions. Whether for packaging, thermoforming, or other industrial applications, Desu delivers high quality PET plastic sheet rolls to suit your requirements.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM