Why choose PET plastic sheet for ESD antistatic electronic parts packing?

In today’s fast-paced electronics industry, the protection of sensitive components from electrostatic discharge (ESD) is of paramount importance. Whether transporting, storing, or handling products such as semiconductors, integrated circuits, or hard drives, ensuring that electronic parts are shielded from static charges is critical to maintaining product integrity.

One of the most effective materials used in ESD protection packaging is PET (Polyethylene Terephthalate) plastic sheet. Here’s why PET plastic sheets are rapidly becoming the material of choice for antistatic electronic parts packaging.

Reason of PET plastic sheet for ESD antistatic electronic parts packing

1. Superior Antistatic Performance

PET plastic sheets offer outstanding ESD protection, preventing static electricity buildup and shielding electronic components from electrostatic discharge. With an excellent rate of static dissipation, PET material helps reduce the risk of ESD-related damage, safeguarding sensitive electronics during handling, transportation, and storage.

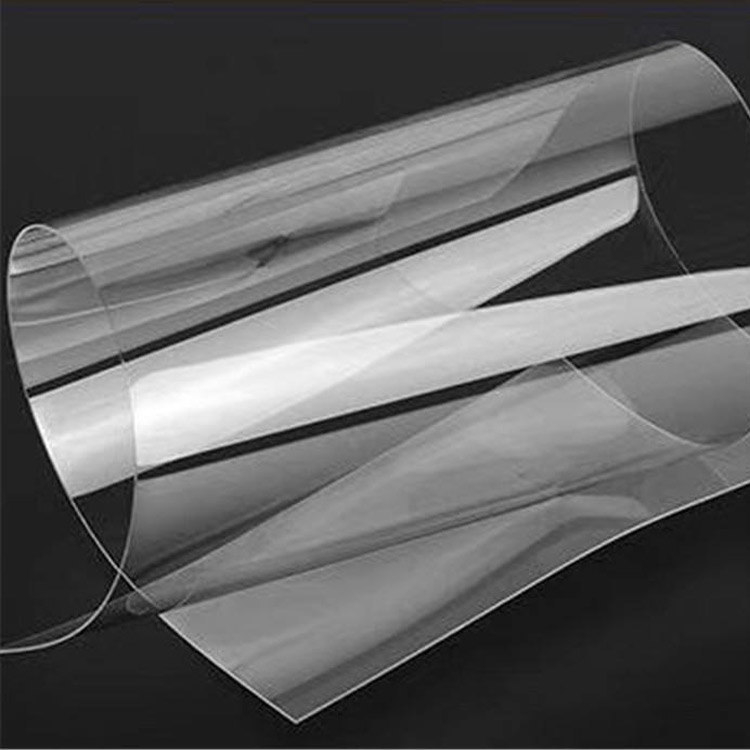

2. High Transparency for Easy Inspection

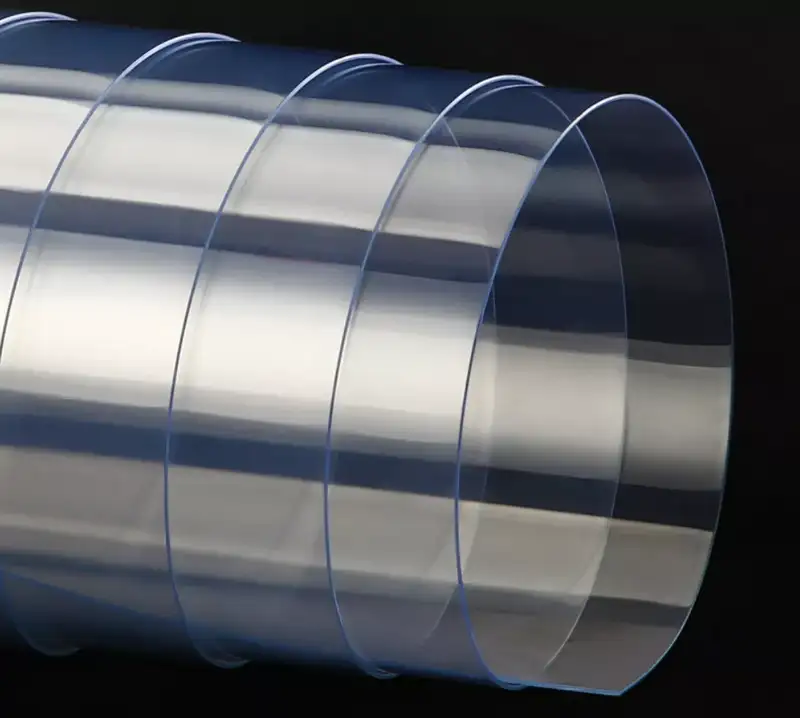

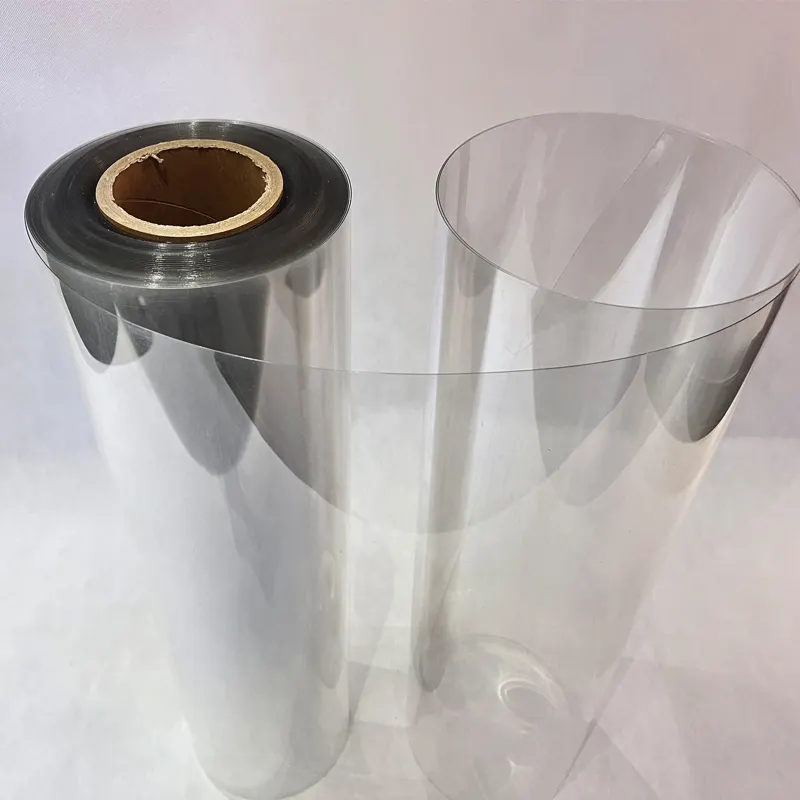

One of the key advantages of PET plastic is its high level of transparency. This allows for easy visual inspection of the electronic parts inside the packaging without the need to open the package. In industries where quality control and verification are critical, the ability to see the contents can save time and prevent damage caused by unnecessary handling.

3. Strength and Durability

Beyond its antistatic properties, PET plastic is known for its impressive strength and durability. PET sheets are tough, resistant to breaking or cracking, and offer long-lasting protection during the shipping and storage of electronic components. This robust material ensures that the integrity of the package remains intact even under rough handling conditions.

4. Environmentally Friendly and Recyclable

As environmental concerns continue to rise, PET stands out as an eco-friendly option. PET plastic is fully recyclable, making it a sustainable choice for businesses looking to reduce their environmental impact. This recyclable nature not only benefits the planet but also supports companies’ green initiatives, aligning with global trends toward sustainability.

5. Customization Options

PET plastic sheets are highly customizable, allowing manufacturers to create packaging solutions tailored to specific needs. Whether it’s creating customized sizes, shapes, or additional protective features, PET can be easily adapted to suit a wide range of electronic parts, offering a versatile solution for packaging that meets both technical and aesthetic requirements.

In the competitive and fast-evolving electronics industry, choosing the right packaging material for sensitive components is crucial. PET plastic sheets provide superior antistatic performance, transparency, durability, and environmental benefits, making them an ideal choice for ESD protection. As the demand for secure and sustainable packaging grows, PET plastic sheets are quickly becoming the material of choice for electronic parts packaging, ensuring that products arrive safely and in optimal condition.

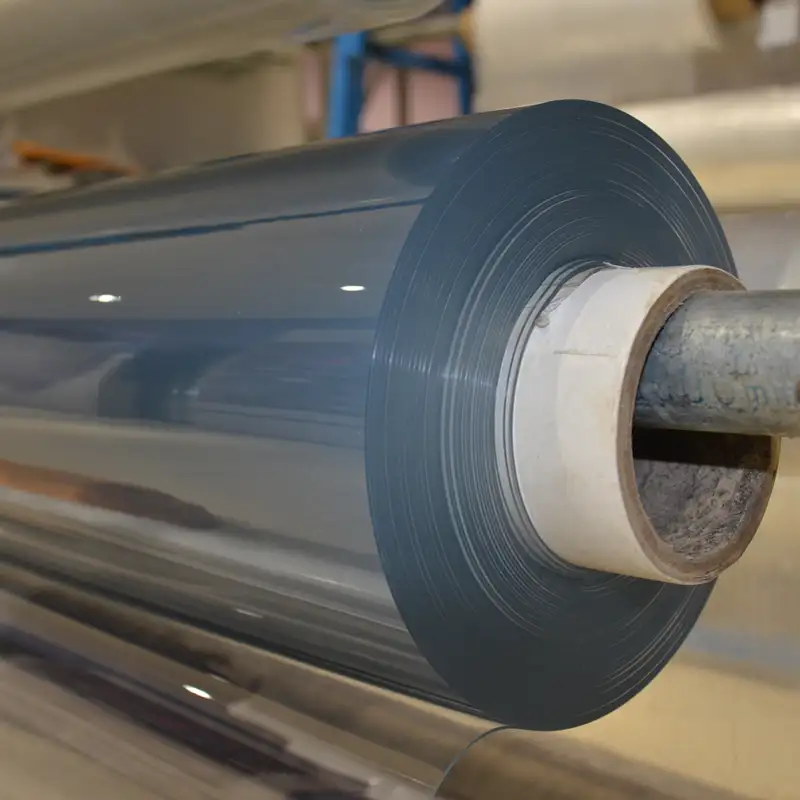

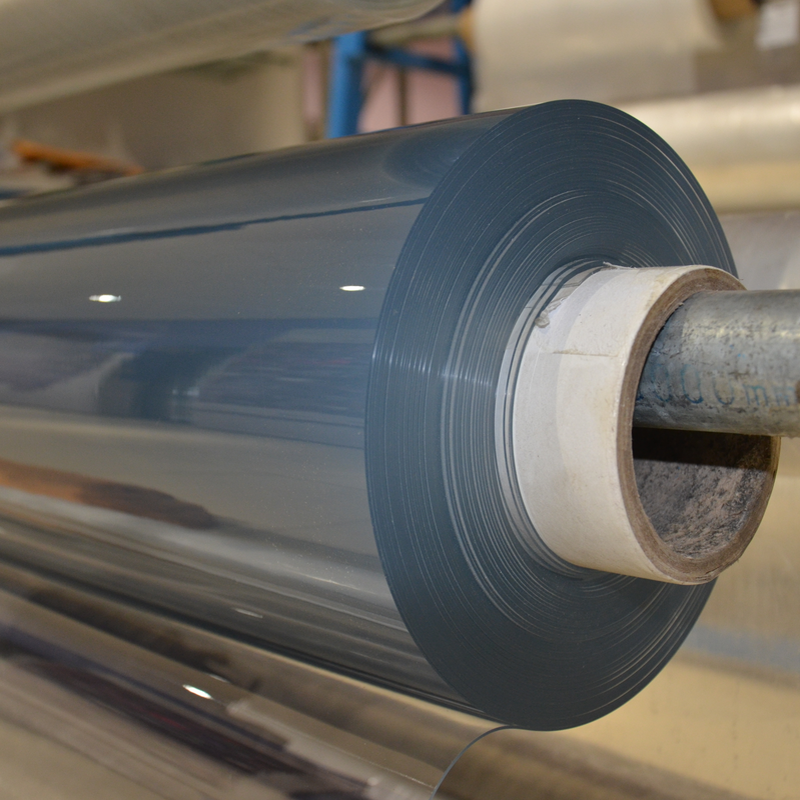

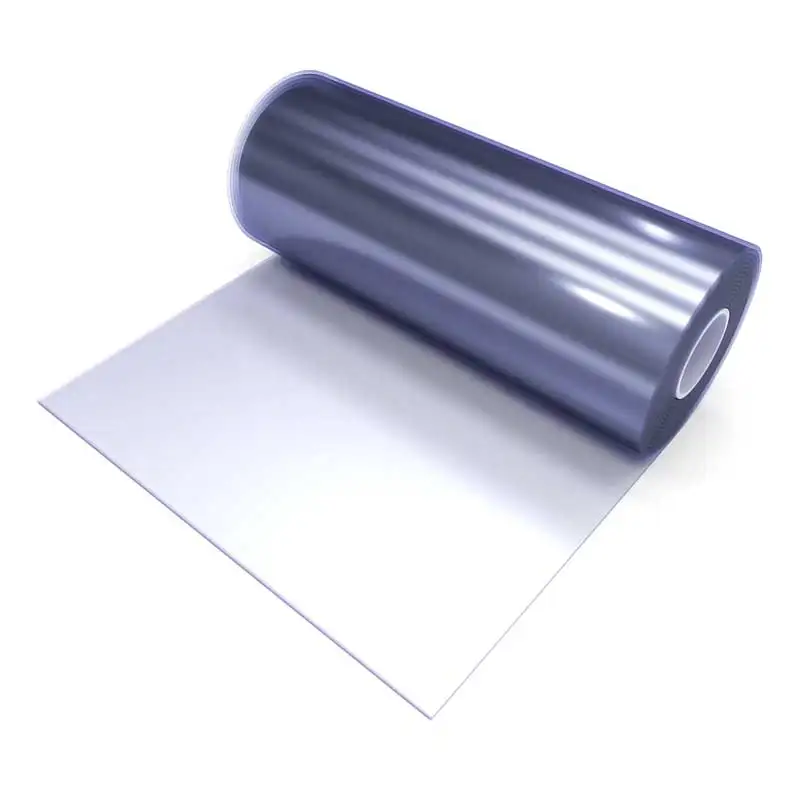

Product Of PET plastic sheet

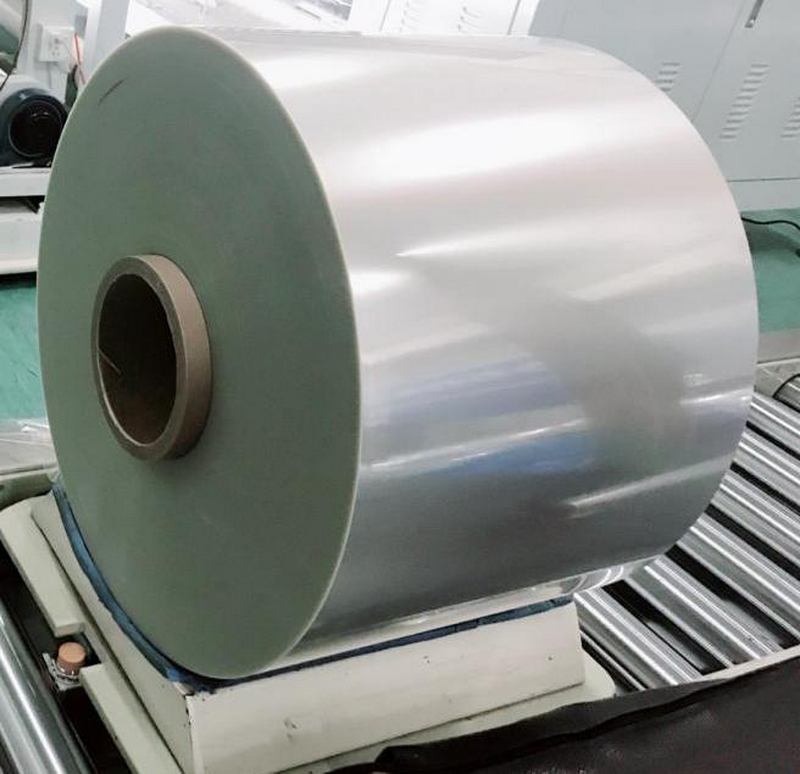

PET plastic sheet (Polyethylene Terephthalate) is a transparent, strong, and durable thermoplastic widely used in packaging, industrial, and consumer goods sectors. It offers excellent transparency, high impact resistance, and abrasion resistance, effectively protecting contents from damage.

In addition, PET sheets are chemically resistant, UV-resistant, and suitable for use in various environments. They also feature excellent antistatic properties, making them ideal for packaging sensitive electronic components. As a recyclable and eco-friendly material, PET aligns with sustainable development trends.

Manufacturing process:

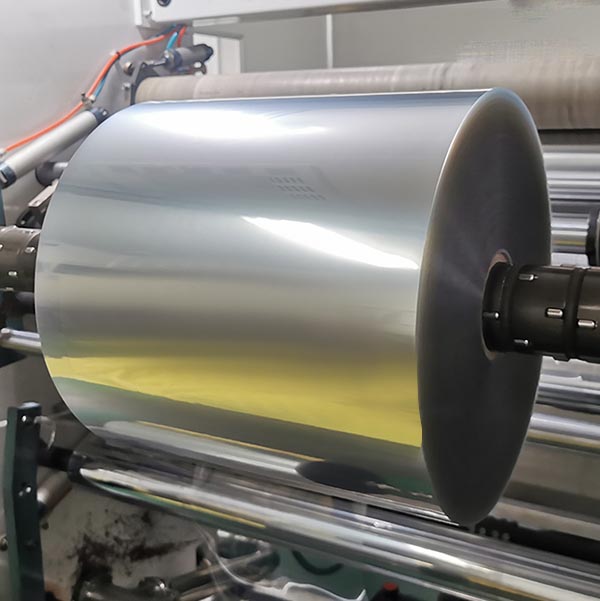

The production process of PET plastic sheets includes: First, polyethylene terephthalate (PTA) and ethylene glycol (EG) are polymerized at high temperature to produce PET resin. Then, the molten resin is extruded into a film, and after cooling, it is stretched and heat-treated to improve its strength, transparency and stability. Finally, the sheet is cut or rolled into the required size and prepared for packaging.

This process ensures that PET sheets have excellent physical properties and are widely used in food packaging, electronic product packaging, pharmaceutical packaging, advertising display and other fields.

What types of PET plastic sheets can be used for ESD anti-static electronic parts packaging?

For ESD anti-static electronic parts packaging, the following types of PET plastic sheets are commonly used:

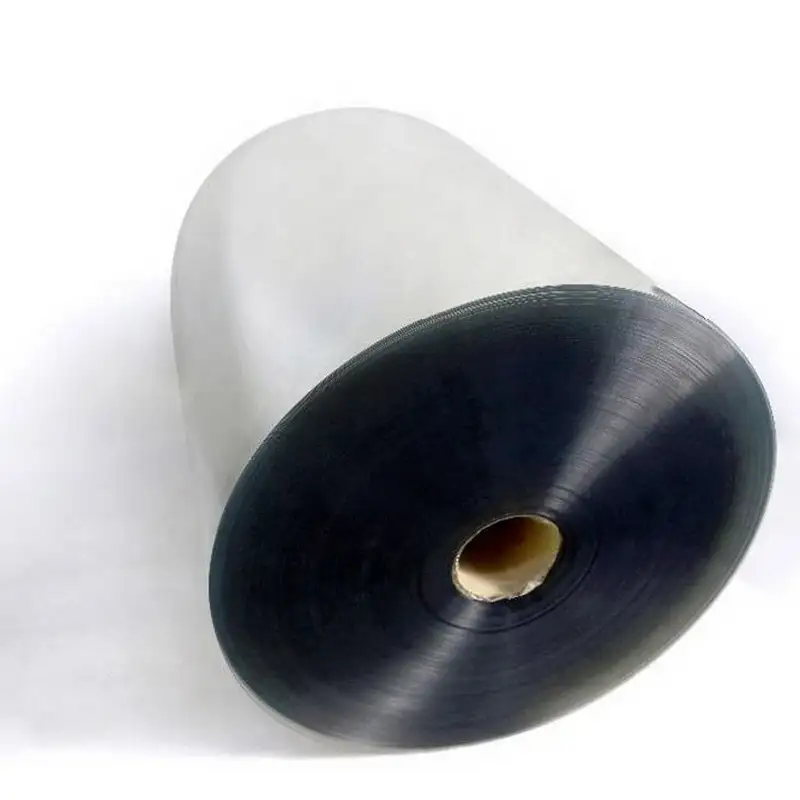

1. Anti-Static PET Plastic Sheets: Treated with additives to prevent static buildup, suitable for general electronic components.

2. Static-Dissipative PET Plastic Sheets: Higher conductivity to slowly dissipate static charges, ideal for sensitive electronics.

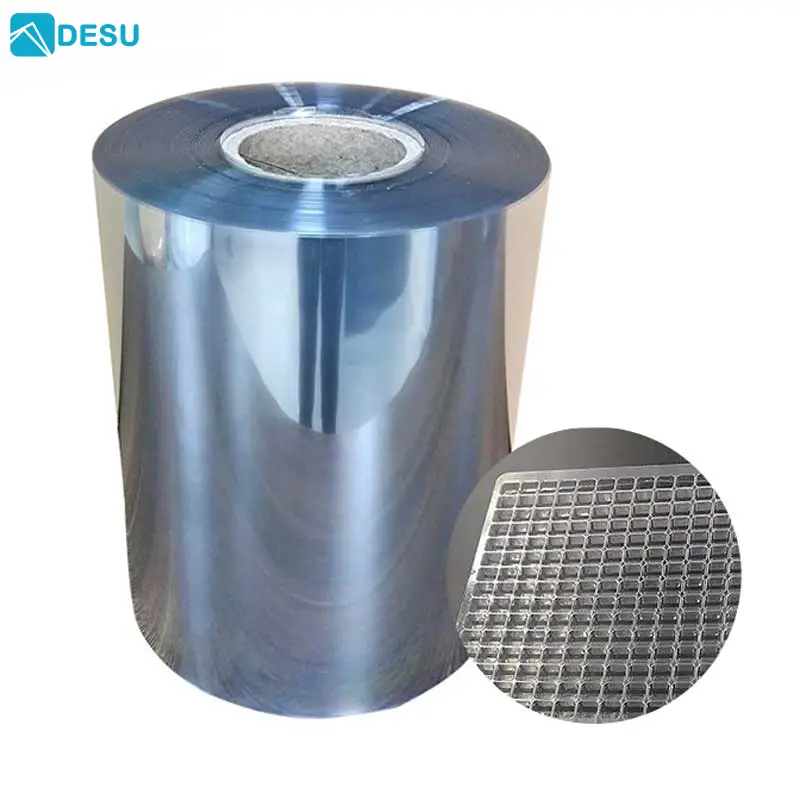

3. Conductive PET Plastic Sheets: Embedded with conductive materials for maximum ESD protection, used in high-precision industries.

4. Coated PET Plastic Sheets: Standard PET with anti-static coatings, balancing transparency and ESD protection.

5. Laminated PET Plastic Sheets: PET laminated with anti-static layers, offering added durability and protection.

Choose based on the required surface resistivity, transparency, and durability for your application.If you would like more information please contact us.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM