Why choose PET plastic sheet rolls as drink cups?

Advantages of PET plastic sheet rolls as drink cups

PET plastic sheet rolls are widely chosen for drink cups due to several advantages:

1. Durability: PET (Polyethylene Terephthalate) plastic sheet rolls is strong, impact-resistant, and offers excellent mechanical properties, making it ideal for handling hot and cold beverages without deforming or breaking.

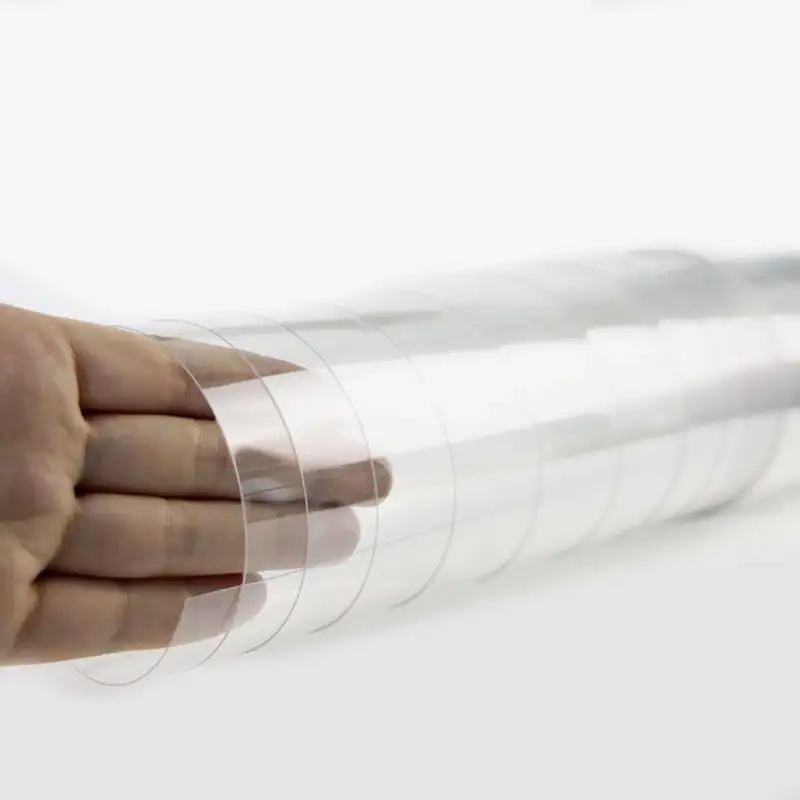

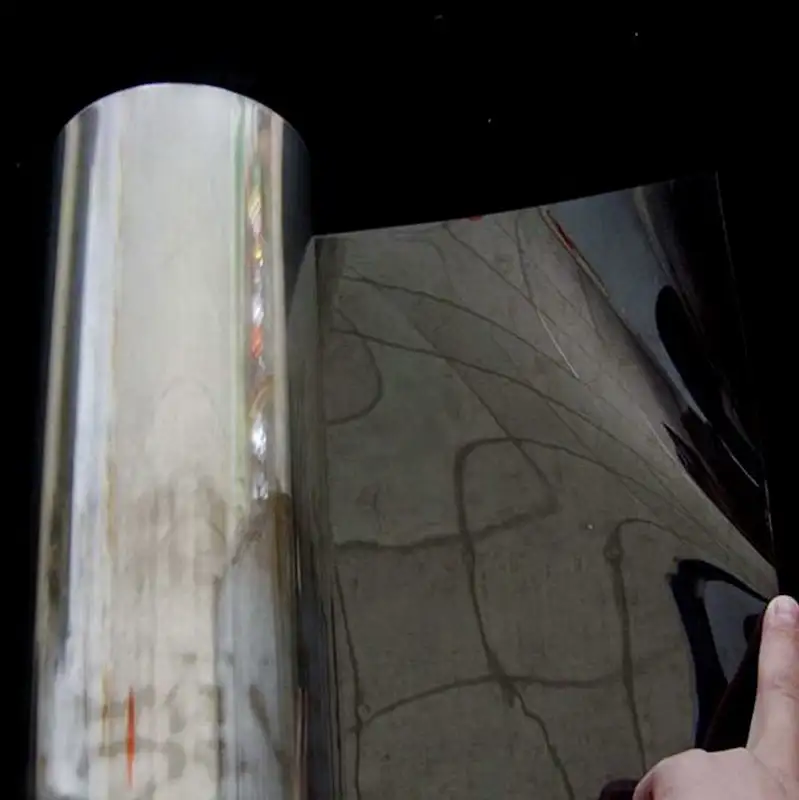

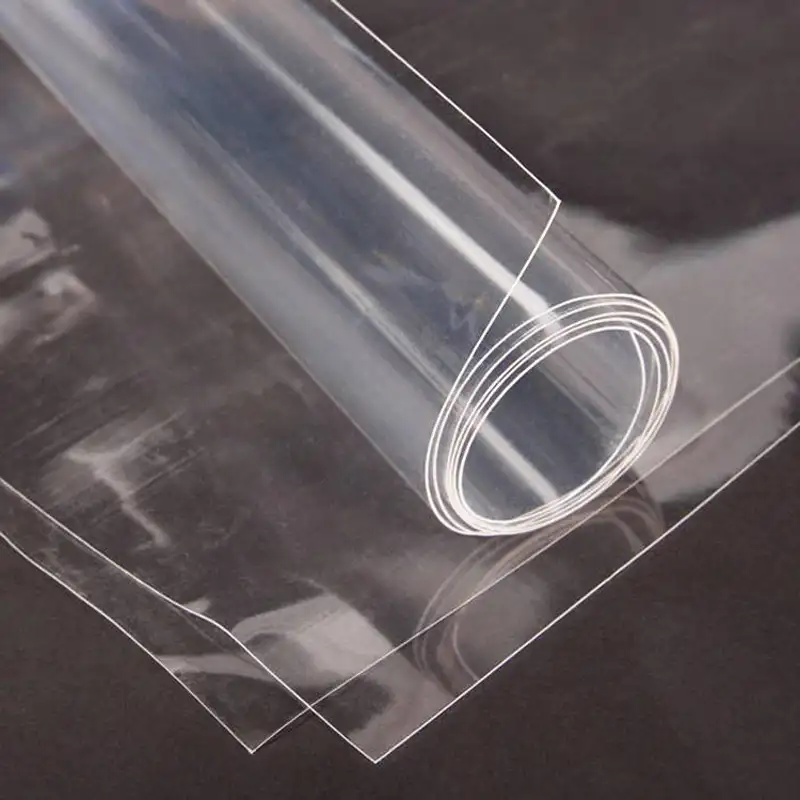

2. Clarity: PET plastic sheet rolls is highly transparent, which enhances the aesthetic appeal of drink cups by showcasing the beverage clearly, making it a popular choice for iced drinks or display purposes.

3. Lightweight: PET plastic sheet roll is lightweight compared to other materials like glass, reducing shipping costs and making it easier for consumers to handle.

4. Recyclability: PET plastic sheet roll is fully recyclable, making it an environmentally preferable option. Many recycling systems can process PET, contributing to sustainability goals.

5. Barrier Properties: PET plastic sheet rolls provides excellent resistance to moisture and gases, preserving the freshness and taste of beverages for longer periods.

6. Food Safety: PET plastic sheet roll is approved for food contact by various health authorities like the FDA, ensuring it’s safe for use with drinks.

These properties make PET plastic sheet rolls a cost-effective and versatile solution for beverage cup manufacturing.

Introduction of PET plastic sheet rolls as drink cups

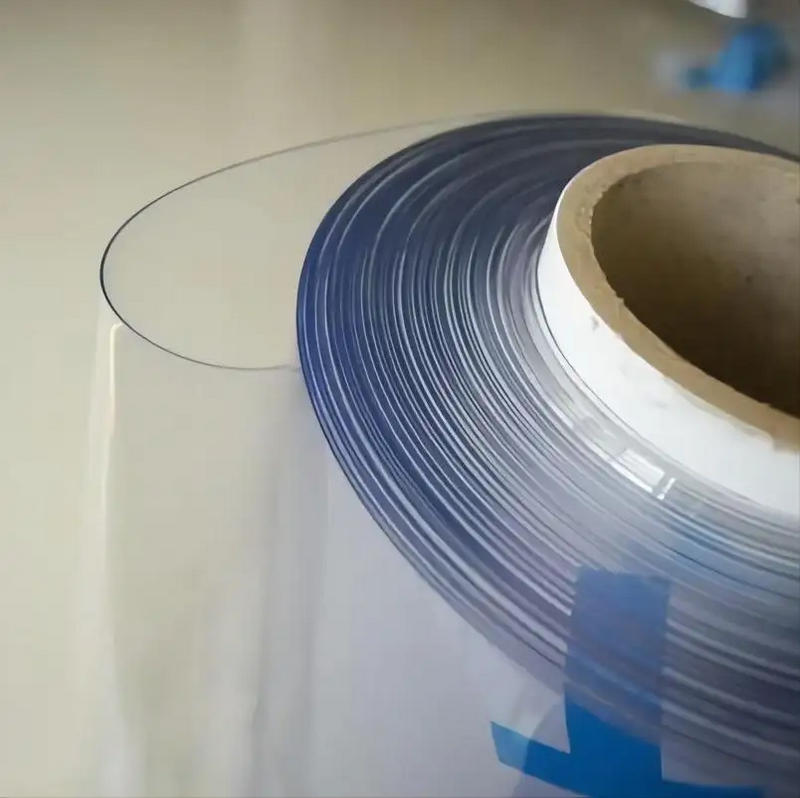

PET (Polyethylene Terephthalate) plastic sheet rolls have become a popular material for manufacturing drink cups, widely used in the beverage industry. PET stands out due to its superior transparency, strength, and food-safe properties, making it ideal for creating both hot and cold beverage containers.

PET plastic is known for its clarity, allowing consumers to see the contents of their drinks clearly, which is especially attractive for cold drinks, bubble tea, and other beverages meant for display. The material is also durable and impact-resistant, preventing cracking or breaking under pressure, which ensures the cup maintains its form during use.

Moreover, PET plastic offers excellent barrier properties, protecting drinks from contamination by moisture, gases, and odors, thus preserving the beverage’s freshness and flavor. Its lightweight nature also makes it convenient for transportation and handling, while reducing shipping costs.

Importantly, PET plastic is 100% recyclable, aligning with sustainability initiatives. This contributes to a reduced environmental footprint when compared to other single-use plastics, as it can be reused for new products through established recycling processes.

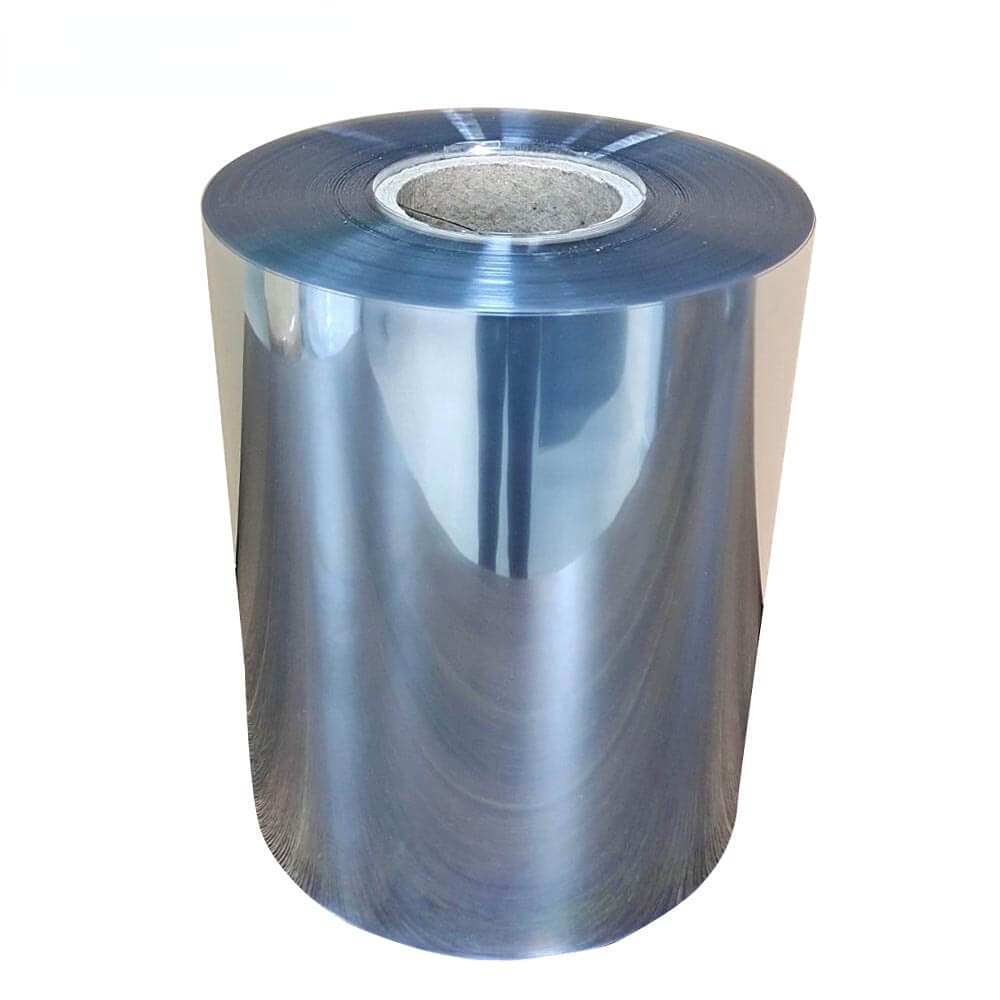

PET plastic sheet rolls as drink cups

PET plastic sheet roll is a packaging material with many advantages and are an ideal choice for toy packaging.

Thickness: 0.18-2.0mm

Width: 300-1400mm

Color: Transparent or Customized

Special performance customization: Anti-fog, Printing, Coating, High impact, Waterproof, Oil-proof, Anti-UV, etc.

Delivery time: 7~15 days since receipt of PO and down payment.

Payment Accepted: D/A, D/P, T/T, L/C, Westunion etc.

Samples: Free samples supply

In summary, PET plastic sheet rolls are widely used for drink cups due to their versatility, cost-effectiveness, and eco-friendly potential, making them a preferred choice in the packaging industry.

Precautions for storing PET plastic sheet rolls

When storing PET plastic sheet rolls, it’s important to follow specific precautions to maintain their quality and ensure they perform well during use. Here are key guidelines:

1. Temperature Control: PET plastic sheet rolls should be stored in a cool, dry environment. Exposure to high temperatures may cause deformation, warping, or degradation of the material, while low temperatures can make the material brittle.

2. Humidity and Moisture Protection: PET plastic sheet rolls are sensitive to moisture absorption, which can affect their mechanical properties and transparency. It’s best to store them in a humidity-controlled space or use moisture-proof packaging.

3. Avoid Direct Sunlight: Prolonged exposure to UV rays from sunlight can cause PET to degrade, becoming discolored or brittle over time. Store the rolls away from direct sunlight to prevent UV damage.

4. Flat Surface Storage: Always store the rolls on a flat, stable surface to prevent bending or uneven stress that could affect the uniformity of the material. Improper storage can lead to deformed rolls, affecting production quality.

5. Dust and Contaminant Prevention: To maintain hygiene and the optical clarity of PET plastic sheet rolls, keep them free from dust, dirt, and other contaminants. Use protective covers or packaging to keep the material clean during storage.

6. Proper Stacking: If stacking rolls, ensure they are stacked evenly with adequate support to avoid crushing the lower rolls. Improper stacking can lead to warping or damage over time.

7. Rotation of Inventory: Use the First-In, First-Out (FIFO) method to avoid long-term storage of PET plastic sheet rolls, which can lead to degradation over time. Regularly rotate stock to use the oldest rolls first.

8. Handling: Avoid dragging or rough handling, as it can lead to scratches or abrasions on the PET plastic sheet rolls, affecting their appearance and usability.

Following these precautions will help preserve the quality and longevity of PET plastic sheet rolls, ensuring they are ready for optimal use in manufacturing processes.

Parameter of PET plastic sheet rolls

| Product name | PET Plastic Sheet Rolls, Polyethylene Terephthalate Sheet, PET Plastic Rolls, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

More Product Recommendations

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM